Well, it still runs like crap, but it runs!

I probably drove it around for about a little over an hour tonight. I also re-spooled the winch line under tension. I almost pulled my Dodge down the driveway....I didn't think that was possible with a small flat fender. The winch seems to work pretty decent for a $175 39 year old winch.

I think I stumbled on why it just wouldn't run before...or at least stay running. The plug over the full vacuum port on the passenger side of the carb was missing. That was causing a major vacuum leak into the carb that was causing some issue with it staying running. Once I plugged that things where a lot better.

It still stumbles and runs pretty rough on the low end, but it runs. I don't think that carb has run in like 2+ years, and it never ran very well before.

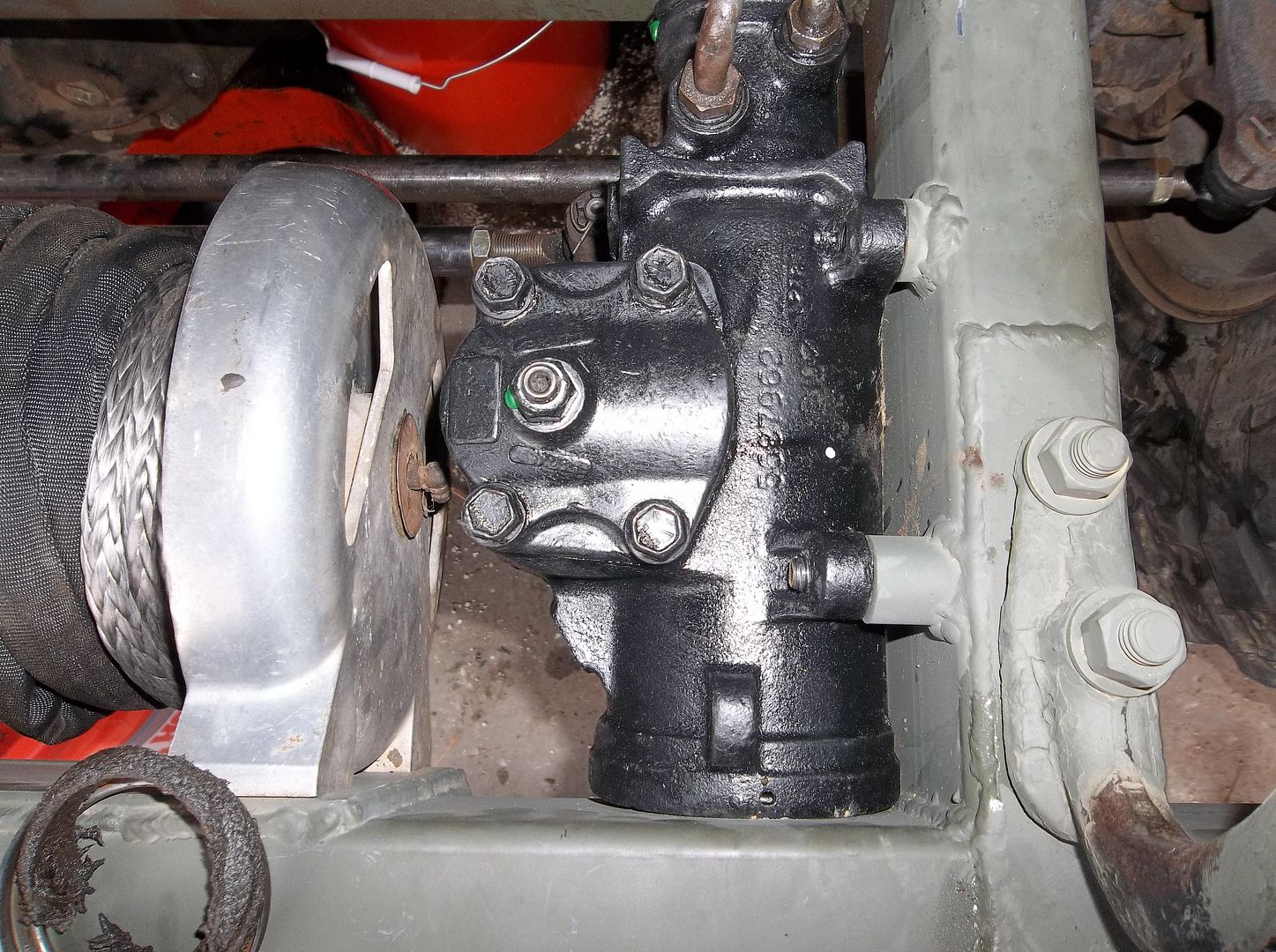

I took my girlfriend for a drive around the neighborhood too. The new steering box feels much better than the old one. The new 4 turn ratio makes it feel much less twitchy with the small steering wheel. I think the steering travel on the box is a little different? I think I need to look for a slightly longer pitman arm...and maybe shorten up the drag link just a little bit.

4wd, hi and low, seemed to work pretty decent. I tried crawling it around next to the road and in the ditch. I think I got the rear end compressed most of the way. I still think I need to add about 1" of shackle to the rear (and add some bumpstops). It twists up pretty decent, at least I never lifted a tire yet

The exhaust leak is still there. I am probably going to need to dig into that one a little bit more, maybe a shim or better clamp or something.

Still need to fix the transmission adapter leak. I am going to tackle that tomorrow evening.

I also need more fuel. I think I am almost out! I do like the sight gauge, it just feel right to check the fuel level like that....

Overall, it feels really good to actually drive it a little bit and put a few more miles on it.

I need to get the motor running better ( mainly carb issues ) and I will be much more happy. I came pretty close to sticking the motorcraft on tonight just to see, but I didn't have an inlet fitting or filter ( and I did try the one from the tank vent...it wasn't the right one )

It did feel REALLY good to get some more seat time and I think it will give me a little more motivation for all the little stuff.