You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rango.....1942 Willys MB

- Thread starter Metcalf

- Start date

Metcalf

Expedition Leader

Tonight I also got the carb back on the intake and did some retuning....

Lesson learned: If you have a vacuum leak, or even think you do, fix it!

With the pesky vacuum leak eliminated under the carb, adapter, and intake I started to tune the carb in again. I am going old school and generally using the autometer vacuum gauge I have installed in the dash ( GREAT IDEA on a carbureted engine! ), my tach, and my ear....

I started by resetting the idle mixture screws to two turns out. I think it works better to be a little rich at idle to start with rather than too lean.

Idle speed was set at about 750rpm

The engine is brought up to full operating temperature on the rich setting.

Once the engine was up to temp I slowly started turning the idle mixture screws in an 1/8 turn at a time on each screw. I noted the vacuum reading with each adjustment. I stopped after the 1st adjustment where I saw no change. This was max vacuum plus 1/8 turn in. For me and my engine this was a rock solid 15" of vacuum on the gauge. There was NO needle bounce this time....none.....

I VERY slightly advanced my base timing at this point causing a slightly idle speed increase.....but no pinging. The vaccum reading SLIGHTY increased. I probably would have tried more advance but ran out of adjustment room. That HEI is TIGHT in there. I will probably need to jump back a tooth and reset base timing again.

Then I lowered the idle speed down to 550-600rpm. At this point I tried one more idle mixture adjustment but didn't see a vacuum increase going 1/8 turn either way so I left the idle mixture alone at this point.

All in all this is the best tune I have seen on the engine so far. All my odd-fire idle roughness went away. The vacuum gauge is ROCK steady at 15". That may sound a little low but I live at 7000ft. The motor just purrs at a 550-600rpm idle......it has never done that before.

Drive-ability is also better than it has ever been. No stumble that I can detect. It's not super 'snappy' really, but it has a 50lb+ flywheel so I am not holding my breath on that one. Power seems good overall. idle to 3000 is great. 3000-4000 is fair. 4000+ starts to feel a bit flat.

I did a little bit of testing in low range 2wd. I don't know if its good or bad but I could NOT stall the motor with the brakes? The front tires just skid and the rear brakes get overridden by the engine. It usually alternates side to side through the Powr-Lok diff. Kinda odd. The engine was pulling down into the 300-400rpm range but that is as low as it would go?

All in all VERY happy!

I think I had an intake leak under the carb AND under the carb adapter.

Now that I have it running sweet I have a few mods I want to try on the carb for better off road performance......

Lesson learned: If you have a vacuum leak, or even think you do, fix it!

With the pesky vacuum leak eliminated under the carb, adapter, and intake I started to tune the carb in again. I am going old school and generally using the autometer vacuum gauge I have installed in the dash ( GREAT IDEA on a carbureted engine! ), my tach, and my ear....

I started by resetting the idle mixture screws to two turns out. I think it works better to be a little rich at idle to start with rather than too lean.

Idle speed was set at about 750rpm

The engine is brought up to full operating temperature on the rich setting.

Once the engine was up to temp I slowly started turning the idle mixture screws in an 1/8 turn at a time on each screw. I noted the vacuum reading with each adjustment. I stopped after the 1st adjustment where I saw no change. This was max vacuum plus 1/8 turn in. For me and my engine this was a rock solid 15" of vacuum on the gauge. There was NO needle bounce this time....none.....

I VERY slightly advanced my base timing at this point causing a slightly idle speed increase.....but no pinging. The vaccum reading SLIGHTY increased. I probably would have tried more advance but ran out of adjustment room. That HEI is TIGHT in there. I will probably need to jump back a tooth and reset base timing again.

Then I lowered the idle speed down to 550-600rpm. At this point I tried one more idle mixture adjustment but didn't see a vacuum increase going 1/8 turn either way so I left the idle mixture alone at this point.

All in all this is the best tune I have seen on the engine so far. All my odd-fire idle roughness went away. The vacuum gauge is ROCK steady at 15". That may sound a little low but I live at 7000ft. The motor just purrs at a 550-600rpm idle......it has never done that before.

Drive-ability is also better than it has ever been. No stumble that I can detect. It's not super 'snappy' really, but it has a 50lb+ flywheel so I am not holding my breath on that one. Power seems good overall. idle to 3000 is great. 3000-4000 is fair. 4000+ starts to feel a bit flat.

I did a little bit of testing in low range 2wd. I don't know if its good or bad but I could NOT stall the motor with the brakes? The front tires just skid and the rear brakes get overridden by the engine. It usually alternates side to side through the Powr-Lok diff. Kinda odd. The engine was pulling down into the 300-400rpm range but that is as low as it would go?

All in all VERY happy!

I think I had an intake leak under the carb AND under the carb adapter.

Now that I have it running sweet I have a few mods I want to try on the carb for better off road performance......

Sean VHA #60013

Adventurer

What you are doing with your mechanical carb is almost a lost art in today's world of computer controlled garbage - good work! BTW, how are the tranny & T-Case doing? Did you ever find a suitable sollution to your front drive-shaft output issue from the t-case?

:coffeedrink:

:coffeedrink:

Metcalf

Expedition Leader

What you are doing with your mechanical carb is almost a lost art in today's world of computer controlled garbage - good work! BTW, how are the tranny & T-Case doing? Did you ever find a suitable sollution to your front drive-shaft output issue from the t-case?

:coffeedrink:

Thanks. I do like the mechanical nature of a simple carb vehicle BUT it has to work well. Re-learning all that has been tough. You don't find many old school people around anymore to gain knowledge from. I have had to do LOTS of reading, thinking, and tinkering.

I am going to run my existing transmission and t-case for a bit longer. This fall/winter I am going to swap it out. The current plan is to use a T18 transmission from an FSJ with the factory D20 adapter which will work for a D18 transfer case also. I will have to change the input shaft out for a short version, drill the GM bolt pattern in the transmission housing, and probably turn down the input retainer a bit.

I have a D20 case ( stronger, large bore, etc ) that I am going to try and make into a 3.15 geared D18 with a set of tera gears.

Using an overdrive is possible with the Tera gears. I am still on the fence about the overdrive......its a lot of money for something I don't really know if I need for my driving style and this vehicle.

These things are never done....

Metcalf

Expedition Leader

Evening test drive....

Opposite lock drifting on loose gravel around a 180 degree hairpin corner isn't as fun as it sounds......good thing I was going uphill. That little ditch on the outside really slowed me down luckily.

A light jeep, big wide tires with a little too much air, a rear Powr-Lok and a good bit more power than before made for an interesting drive!

All in all the carb tuning paid off. It wasn't a fluke. The engine fired right up after sitting for 24 hours or more with just a tap of the accelerator pedal. The idle is nice and clean at 550-600rpm with 15-15.5" of vacuum. The engine temp seemed stable in the 170-190 range for the most part. I didn't try and push it for a long time, like the gentle up canyon drive in 4th gear at 45 home coming home from work. In general I think the engine runs a little bit cooler than before but that might be a stretch.

If anything the carb feels a little fat/rich now. I have #47 jets, 1.08 primary autolite 2100, 225" motor, 7000ft elevation. My gut feeling is I need to drop down the jet size or three. I should probably order up a few different sizes. With these jets being factory on a 302(ish) motor I think I will only need to go down in size? I can't imagine needing to go up with this motor currently. Is there any kind of calculation for jet size changes by elevation?

I also played around with the brake proportioning valve. I got the front brakes dialed in a little bit more now. It seems to stop much better but still locks up the rear tires on gravel first with the weight transfer?

Anyways....fun....

Opposite lock drifting on loose gravel around a 180 degree hairpin corner isn't as fun as it sounds......good thing I was going uphill. That little ditch on the outside really slowed me down luckily.

A light jeep, big wide tires with a little too much air, a rear Powr-Lok and a good bit more power than before made for an interesting drive!

All in all the carb tuning paid off. It wasn't a fluke. The engine fired right up after sitting for 24 hours or more with just a tap of the accelerator pedal. The idle is nice and clean at 550-600rpm with 15-15.5" of vacuum. The engine temp seemed stable in the 170-190 range for the most part. I didn't try and push it for a long time, like the gentle up canyon drive in 4th gear at 45 home coming home from work. In general I think the engine runs a little bit cooler than before but that might be a stretch.

If anything the carb feels a little fat/rich now. I have #47 jets, 1.08 primary autolite 2100, 225" motor, 7000ft elevation. My gut feeling is I need to drop down the jet size or three. I should probably order up a few different sizes. With these jets being factory on a 302(ish) motor I think I will only need to go down in size? I can't imagine needing to go up with this motor currently. Is there any kind of calculation for jet size changes by elevation?

I also played around with the brake proportioning valve. I got the front brakes dialed in a little bit more now. It seems to stop much better but still locks up the rear tires on gravel first with the weight transfer?

Anyways....fun....

give it a week and read the plugs before ya go and order up some jets. I would also get a bit off camber on some hill sides and do a few climbs to make sure its not sputtering out on you. You can always raise the float a bit to help with the off camber situations, but that will make it run rich so you will have to go deeper into the jets to compensate for the higher float setting.

If you can get hold of a dial timing light you could figure out your total advance and then get the base into the area you want.

If you can get hold of a dial timing light you could figure out your total advance and then get the base into the area you want.

Metcalf

Expedition Leader

It is drive your Willys to work friday again...

I think if I had a transmission and transfer case I trusted more I would drive it to work every day! I think now I am starting to get a lot of the bugs ironed out and its really starting to be enjoyable to drive.

Things that I noticed today...

-The new steering ratio is for sure a little quicker. Having all my steering side to side is nice. Now its starting to feel like a short wheelbase maneuverable vehicle.

-The new carb tuning seems to be paying off. I'm fairly sure its rich, but even with just the vacuum leak fixed and the idle mixture tuned it seems to have more power in the 1750-2000rpm range when driving at 45ish in 4th gear. I will be interesting to see how the trip home goes this afternoon when its warmer. All in all though I think I am getting somewhere with the engine tuning now. I didn't notice any pinging or anything with the slightly advanced timing. Light throttle cruise is in the 14" range. Part throttle ( most of my normal driving ) seem to be in the 11" range. You have to get into the throttle pretty heavy to get the powervalve to kick in. I think its working right however. Before I think with the lower vacuum I was seeing I was driving on the power valve more.....

-The transmission and t-case I just don't really trust for high speed stuff. I need to check the gear oil level again. I need to get my replacements built. I think with a nice new transmission and t-case using normal adapter parts and gears.....it should be really enjoyable to drive around. 5.38 gears will help that too. If only I had $3000 to spend today. A nice fresh T18 from Novak and a 3.15 geared D18 transfer case ( and throw in an overdrive too...why not )

-I am pretty sure I want to try and pull off an external hydraulic clutch when I swap the motor. I have the spare motor to mock things up on now. I need to get to measuring all that stuff. The novak kit for $200 seems a little ridiculous. Factory parts....just don't know. Maybe a pull type external slave from the racing market?

-The rear suspension feels better with the longer shackles. I think with two people and some gear it will be even better. I am kinda hoping the springs break in a little more. Its still a little choppy on concrete. I need to get some bumpstops on it all around for the really big bumps. I have been looking at the Belltech 4923 units. They are a foam progressive bumpstop. 2.5" dia, 2" tall. That should give me just about 2-3" uptravel before the bumpstops hit and then 2" of nice foam bumpstop. They look like a rebadged OEM unit but off what I have no idea.

-Having an extra inch of suspension height on the rear end helped the visibility a bit. Now at my normal lazy seating position I can see the end of the hood. I find it funny all the small things you notice when driving this thing.

Fun Fun.

I think if I had a transmission and transfer case I trusted more I would drive it to work every day! I think now I am starting to get a lot of the bugs ironed out and its really starting to be enjoyable to drive.

Things that I noticed today...

-The new steering ratio is for sure a little quicker. Having all my steering side to side is nice. Now its starting to feel like a short wheelbase maneuverable vehicle.

-The new carb tuning seems to be paying off. I'm fairly sure its rich, but even with just the vacuum leak fixed and the idle mixture tuned it seems to have more power in the 1750-2000rpm range when driving at 45ish in 4th gear. I will be interesting to see how the trip home goes this afternoon when its warmer. All in all though I think I am getting somewhere with the engine tuning now. I didn't notice any pinging or anything with the slightly advanced timing. Light throttle cruise is in the 14" range. Part throttle ( most of my normal driving ) seem to be in the 11" range. You have to get into the throttle pretty heavy to get the powervalve to kick in. I think its working right however. Before I think with the lower vacuum I was seeing I was driving on the power valve more.....

-The transmission and t-case I just don't really trust for high speed stuff. I need to check the gear oil level again. I need to get my replacements built. I think with a nice new transmission and t-case using normal adapter parts and gears.....it should be really enjoyable to drive around. 5.38 gears will help that too. If only I had $3000 to spend today. A nice fresh T18 from Novak and a 3.15 geared D18 transfer case ( and throw in an overdrive too...why not )

-I am pretty sure I want to try and pull off an external hydraulic clutch when I swap the motor. I have the spare motor to mock things up on now. I need to get to measuring all that stuff. The novak kit for $200 seems a little ridiculous. Factory parts....just don't know. Maybe a pull type external slave from the racing market?

-The rear suspension feels better with the longer shackles. I think with two people and some gear it will be even better. I am kinda hoping the springs break in a little more. Its still a little choppy on concrete. I need to get some bumpstops on it all around for the really big bumps. I have been looking at the Belltech 4923 units. They are a foam progressive bumpstop. 2.5" dia, 2" tall. That should give me just about 2-3" uptravel before the bumpstops hit and then 2" of nice foam bumpstop. They look like a rebadged OEM unit but off what I have no idea.

-Having an extra inch of suspension height on the rear end helped the visibility a bit. Now at my normal lazy seating position I can see the end of the hood. I find it funny all the small things you notice when driving this thing.

Fun Fun.

Metcalf

Expedition Leader

I've been playing around with some mods on my autolite 2100 to hopefully make it work even better....

When I rebuilt the carb I noticed that I had a few different options in the kit for the top cover gasket.....

This is the one that fit. Notice the hole at the back of the bowl and the large window cut out over the float.

This one almost fit. The rear holes don't line up. I was looking at the gasket thinking that the three holes might be a better idea. Basically, on an autolite/motorcraft 2100 the gasket could provide a baffle between the fuel in the fuel bowl and the vent tubes in the carb top. My autolite has two identical vent tubes that are in the rear corners of the bowl.

In the version that fits the carb there is a fairly direct path for the fuel to slosh through the gasket that fits. In the version that didn't fit ( because of the bolt pattern ) the fuel sloshing would have to take a longer path from the bowl and out of the vents.

So, why not improve it even more.....

I cut a piece of flat gasket material and used the gasket that fit to make a template.

A little silver sharpie and I had a nice outline. You just have to remember what side of the line to cut on for the best fit.

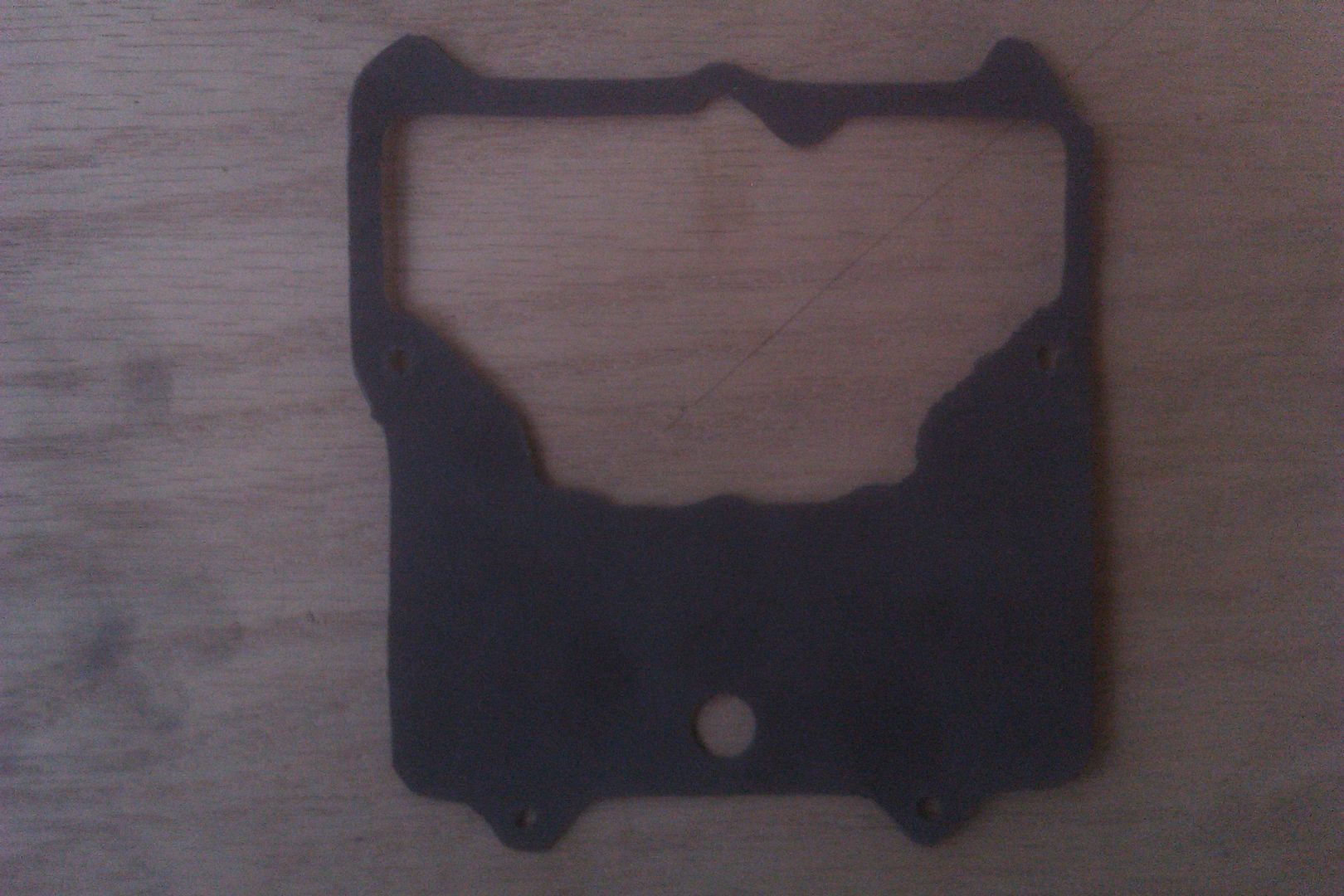

After a few minutes on the couch with a plywood scrap base and a razor blade I had this.

Here is version 1.0 of my new slosh-proofer autolite 2100 wiz bang top cover gasket. The thinking behind is that in order for the fuel to slosh out of the bowl through the vents it has to travel the maximum distance possible. The vent hole in the gasket is at the forward part of the bowl. On a steep up hills the fuel bowl has to be totally full, far beyond normal float level I hope. I can't quite predict how the float act with high nose up carb angles but I am working on a way to test that. This should also help keep the fuel from just randomly bouncing and sloshing out of the bowl when going over rough roads better than the original gasket I think.

Going down hill the vents are at the rear of the bowl so it should be nearly impossible for fuel to slosh out the vents. Having the fuel slosh away from the jets is another thing....working on that. One other thing that the 2100 has going for it is that the jets are both in the bottom middle of the bowl. This SHOULD keep the jets in fuel more often than your typical Holley jet location up on the side of the bowl and farther apart from each other.

The size of the vents is another area I am working on. Your typical Holley fuel bowl has a vent tube less than 1/4" in diameter I think? My autolite has two .390 diameter vents! I don't see why these can't be reduced in diameter significantly to help with the rate at which fuel can slosh out of the bowl, or run out of the bowl into the throat at steep nose up angles?

One of my other favorite things about the autolite is that the carb design has no gasket under the fuel in the bowl ( other then the power valve and accelerator pump which are secondary ). You can pull the top off the carb and visually inspect your float level. I have found that that with the engine at 200F and shut off the engine.....most of the fuel will boil out of the bowl. Not all of it, but most of it is gone. I am adding a heat isolating gasket to help with this. The next step is a non-metal carb adapter.

With a pair of vise grips on the fuel input line you can also remove the float and needle and change out the jets without spilling a drop of fuel.

More soon....

When I rebuilt the carb I noticed that I had a few different options in the kit for the top cover gasket.....

This is the one that fit. Notice the hole at the back of the bowl and the large window cut out over the float.

This one almost fit. The rear holes don't line up. I was looking at the gasket thinking that the three holes might be a better idea. Basically, on an autolite/motorcraft 2100 the gasket could provide a baffle between the fuel in the fuel bowl and the vent tubes in the carb top. My autolite has two identical vent tubes that are in the rear corners of the bowl.

In the version that fits the carb there is a fairly direct path for the fuel to slosh through the gasket that fits. In the version that didn't fit ( because of the bolt pattern ) the fuel sloshing would have to take a longer path from the bowl and out of the vents.

So, why not improve it even more.....

I cut a piece of flat gasket material and used the gasket that fit to make a template.

A little silver sharpie and I had a nice outline. You just have to remember what side of the line to cut on for the best fit.

After a few minutes on the couch with a plywood scrap base and a razor blade I had this.

Here is version 1.0 of my new slosh-proofer autolite 2100 wiz bang top cover gasket. The thinking behind is that in order for the fuel to slosh out of the bowl through the vents it has to travel the maximum distance possible. The vent hole in the gasket is at the forward part of the bowl. On a steep up hills the fuel bowl has to be totally full, far beyond normal float level I hope. I can't quite predict how the float act with high nose up carb angles but I am working on a way to test that. This should also help keep the fuel from just randomly bouncing and sloshing out of the bowl when going over rough roads better than the original gasket I think.

Going down hill the vents are at the rear of the bowl so it should be nearly impossible for fuel to slosh out the vents. Having the fuel slosh away from the jets is another thing....working on that. One other thing that the 2100 has going for it is that the jets are both in the bottom middle of the bowl. This SHOULD keep the jets in fuel more often than your typical Holley jet location up on the side of the bowl and farther apart from each other.

The size of the vents is another area I am working on. Your typical Holley fuel bowl has a vent tube less than 1/4" in diameter I think? My autolite has two .390 diameter vents! I don't see why these can't be reduced in diameter significantly to help with the rate at which fuel can slosh out of the bowl, or run out of the bowl into the throat at steep nose up angles?

One of my other favorite things about the autolite is that the carb design has no gasket under the fuel in the bowl ( other then the power valve and accelerator pump which are secondary ). You can pull the top off the carb and visually inspect your float level. I have found that that with the engine at 200F and shut off the engine.....most of the fuel will boil out of the bowl. Not all of it, but most of it is gone. I am adding a heat isolating gasket to help with this. The next step is a non-metal carb adapter.

With a pair of vise grips on the fuel input line you can also remove the float and needle and change out the jets without spilling a drop of fuel.

More soon....

jeepdreamer

Expedition Leader

Simple is good.

I read in JP magazine where DUI is working on a smaller cap HEI for the Buick motor. It also has a longer shaft area to clear the manifold which gives ya more room to adjust the dizzy. Just thought you'd maybe be interested?

I read in JP magazine where DUI is working on a smaller cap HEI for the Buick motor. It also has a longer shaft area to clear the manifold which gives ya more room to adjust the dizzy. Just thought you'd maybe be interested?

jeepdreamer

Expedition Leader

Yeah... sounds steep. Esp. when you think you find all the CHI-knock offs on fleabay for less than half. There is honestly a huge difference in quality. DUI does it right, builds it specifically for the odd odd fire, and engineers them to work and last. IIRC, you actually get the specs/performance sheet from where they bench test it before it leaves their QC and ships. I've run a few of them I bought used on AMC motors and have never been disappointed. Hard to swallow the buy in cost, sure. But it is an outstanding set up worth its cost IMHO. Maybe not so warranted in your mostly stock situation but there is huge potential in that lil V6... the grand father of the Buick Grand National, remember?  But for the cost of a new (not reman) stock dizzy and a HP coil your probably not ridiculously far off. Plus a self contained unit does help clean up the clutter. Just thought I'd toss the idea out to ya.

But for the cost of a new (not reman) stock dizzy and a HP coil your probably not ridiculously far off. Plus a self contained unit does help clean up the clutter. Just thought I'd toss the idea out to ya.

Metcalf

Expedition Leader

I already have an odd-fire HEI conversion though  I think I paid $20 for it from the pick and pull....

I think I paid $20 for it from the pick and pull....

The only thing that is a pain is getting the distributor in a spot where you can adjust it enough. You have to replace one of the intake bolts with a small button head and grind the corner of the intake down slightly. Then....you just pick a rotation that works best. The upper radiator hose is a tight fit with the large HEI cap also. It works though....

The only thing that is a pain is getting the distributor in a spot where you can adjust it enough. You have to replace one of the intake bolts with a small button head and grind the corner of the intake down slightly. Then....you just pick a rotation that works best. The upper radiator hose is a tight fit with the large HEI cap also. It works though....

Similar threads

- Replies

- 7

- Views

- 787

- Replies

- 4

- Views

- 2K

- Replies

- 65

- Views

- 6K