Metcalf

Expedition Leader

not a ton tonight. I had some dog containment upgrades to do....

I did get a pair of setup bearings made for the Dana 30 carrier. I used the Jantz method of honing the bearings out with a flap wheel in a die grinder. It took a little bit but worked well!

I also measured the free space in the carrier. That was between .060" and .061"

Hopefully tomorrow I can get the pinion in place using the headstamp as a base, measure the carrier to pinion space, and get the 1st set of shims on the carrier. I am very interested to see how close the Dana/Spicer head measurement is?

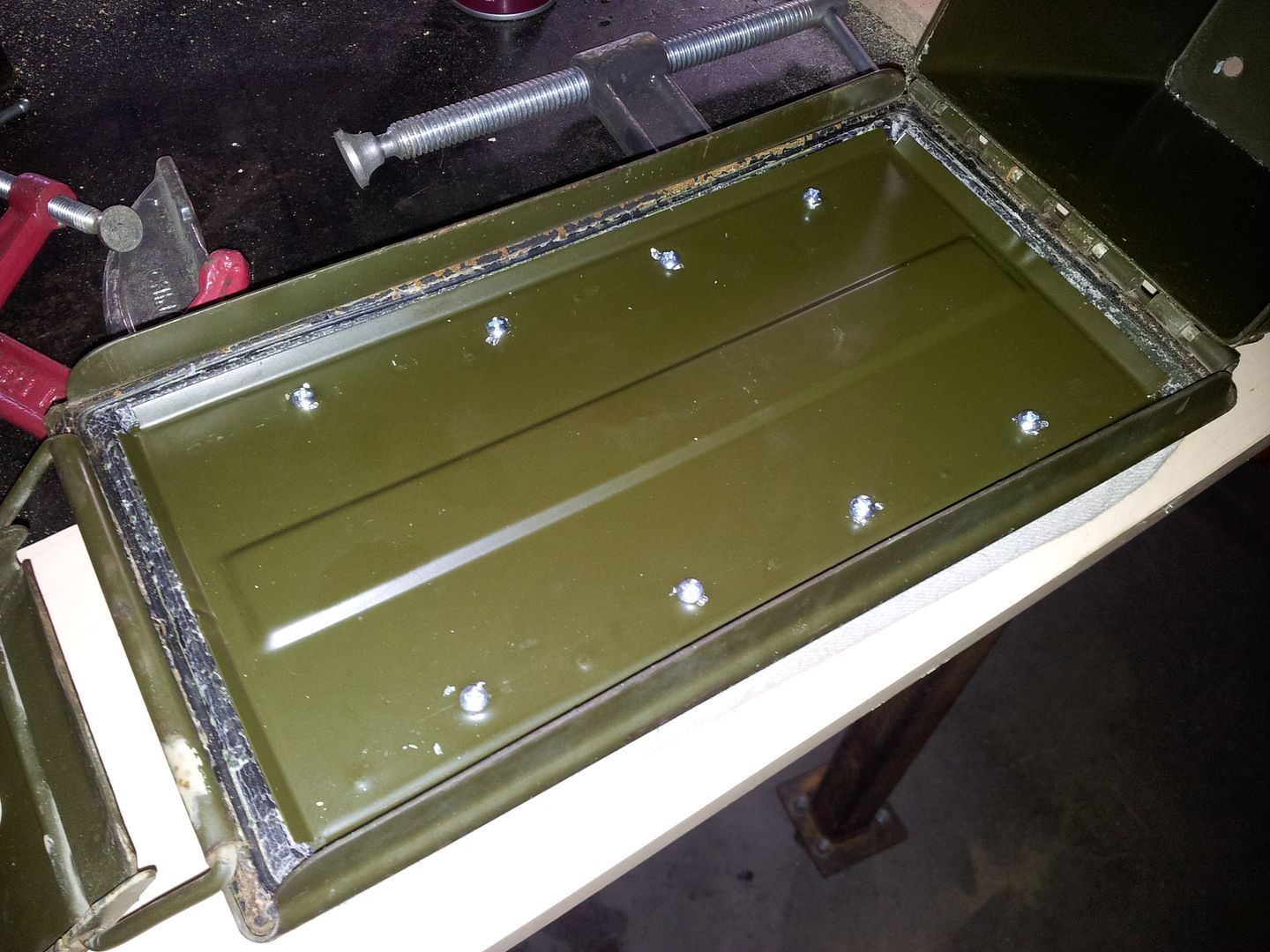

I did finally get my shovel and axe brackets in the mail. I will have to see if I can find the right hardware tomorrow after work. It will be nice to have that stuff mounted. I guess I need to make some straps too.

More tomorrow....

I did get a pair of setup bearings made for the Dana 30 carrier. I used the Jantz method of honing the bearings out with a flap wheel in a die grinder. It took a little bit but worked well!

I also measured the free space in the carrier. That was between .060" and .061"

Hopefully tomorrow I can get the pinion in place using the headstamp as a base, measure the carrier to pinion space, and get the 1st set of shims on the carrier. I am very interested to see how close the Dana/Spicer head measurement is?

I did finally get my shovel and axe brackets in the mail. I will have to see if I can find the right hardware tomorrow after work. It will be nice to have that stuff mounted. I guess I need to make some straps too.

More tomorrow....