Metcalf

Expedition Leader

Tonight's progress....

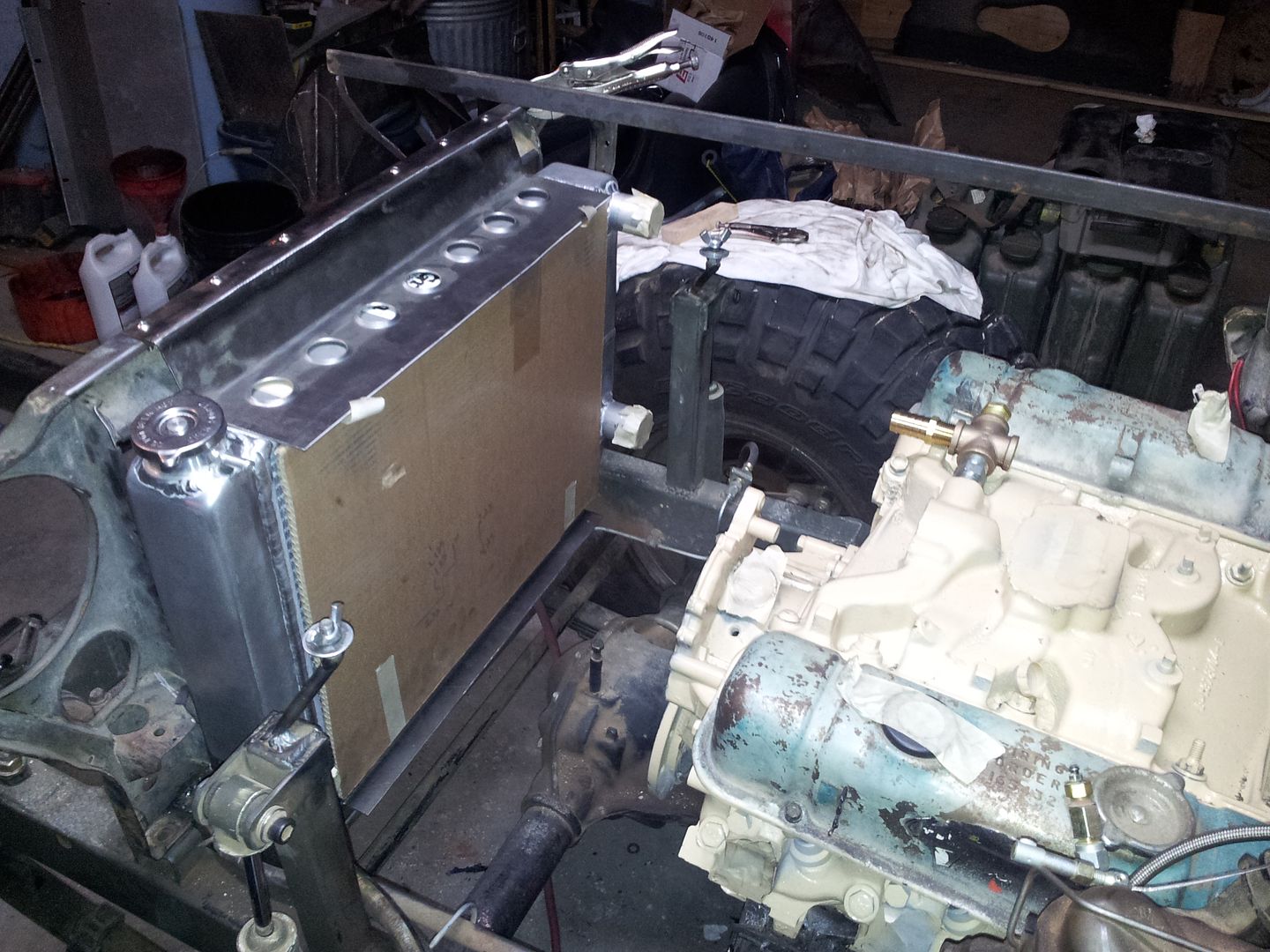

The upper mount is getting close. It will also form the upper mount for the radiator shroud if all goes according to plan. It was kinda a pain in the rear to make. It is two parts. There is a slight curve to the top of the flat fender grill shell so that flange couldn't really be bent. There was a lot of grinding and fitting of the two parts. They where then tack welded on the outside. Then I pulled the bracket and welded the back side of the seam. The top was welded and ground down smooth.

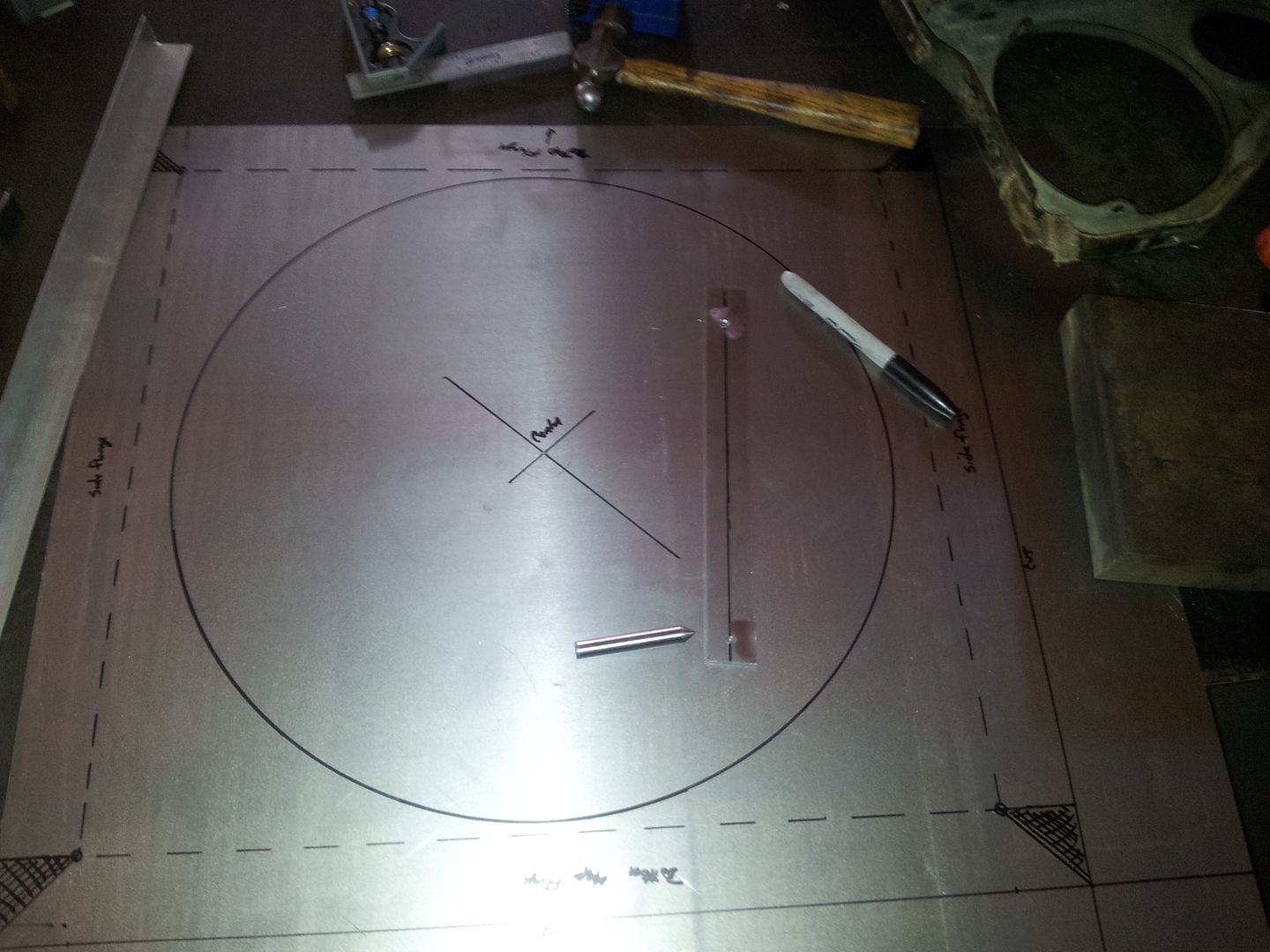

I added some dimpled holes. I slightly reconfigured my dimple die so that there was a little LESS clearance between the die. This have a MUCH flatter finished product.

All in all I am pretty happy so far.

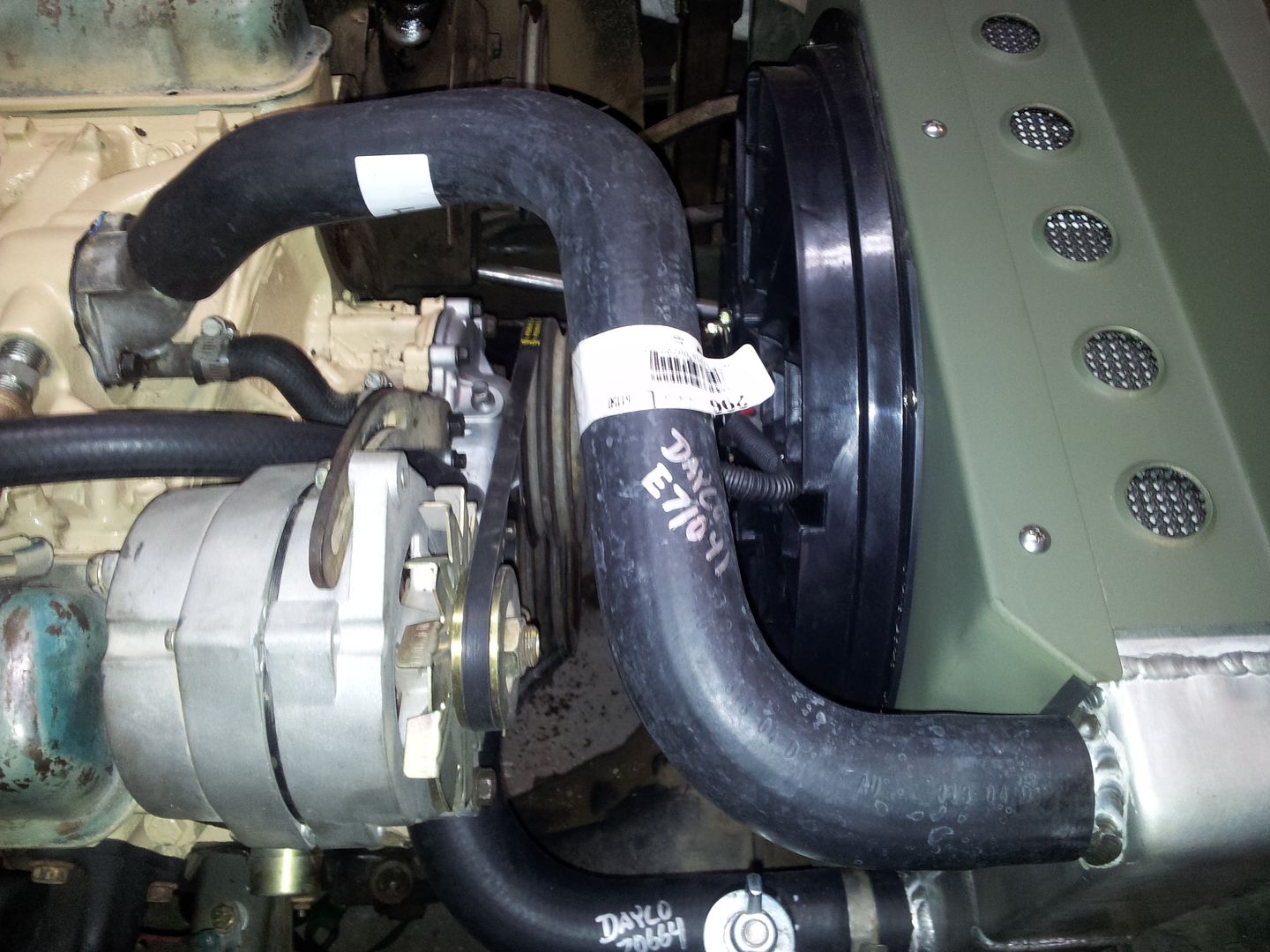

I need to work on putting the mounting hardware for the bottom bracket in tomorrow. I have an idea for an inner brace for the bottom bracket I want to try so that all the weight of the radiator isn't on the bottom flange alone. Then I should be able to move onto the shroud and fan mount.

The upper mount is getting close. It will also form the upper mount for the radiator shroud if all goes according to plan. It was kinda a pain in the rear to make. It is two parts. There is a slight curve to the top of the flat fender grill shell so that flange couldn't really be bent. There was a lot of grinding and fitting of the two parts. They where then tack welded on the outside. Then I pulled the bracket and welded the back side of the seam. The top was welded and ground down smooth.

I added some dimpled holes. I slightly reconfigured my dimple die so that there was a little LESS clearance between the die. This have a MUCH flatter finished product.

All in all I am pretty happy so far.

I need to work on putting the mounting hardware for the bottom bracket in tomorrow. I have an idea for an inner brace for the bottom bracket I want to try so that all the weight of the radiator isn't on the bottom flange alone. Then I should be able to move onto the shroud and fan mount.