Lots o' fun today! I went out to the shop about 10am and the next time I looked up it was 4pm....

I had some annoyingly large holes I needed to weld up. I made some plugs buy turning down some small round stock in the lathe and then cutting them to thickness on the bandsaw. This seems to work really well. If you make them a touch thicker than the base metal they clean up a little nicer.

If I can I hole them in place with a magnet on the back of the panel. You can also use a corner of the magnet of you have to hold from the front of the panel. Remove the magnet after you get it tacked in place.

A little primer and paint and things looked a little bit better than before. One of these days I would love have a straight new tub to work from....

I threw the spare engine up on my new engine stand. Anyone need any misc stock parts? This had a lot of the little OE stuff.....fuel lines, brackets, a stock carb, points distributor, etc.

After a few hours I had this....

It seems pretty clean. It is still 3.750" bore. The cylinders are smooth with no nicks or gouges. Cylinder #4 had a water mark in it and a touch of rust. I don't know if this was from a leaky head gasket. The pistons are stock units with the nipple in the middle. There was some light carbon flakes on the top of a few pistons. The plugs looked like it was running rich.

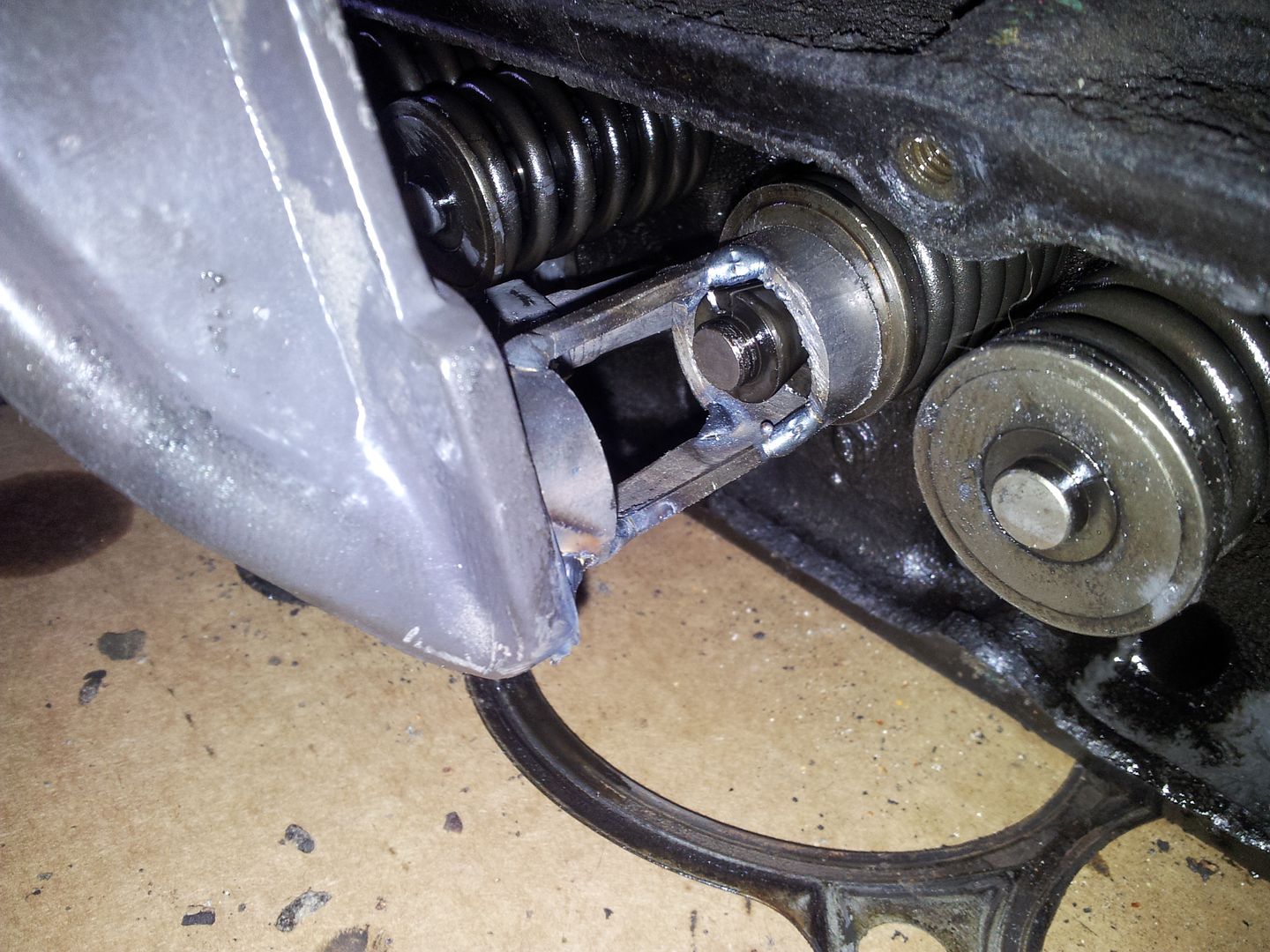

The story I got on this engine was that it perhaps skipped on the timing at some point. I ran the timing chain around and both dots lined up. The timing chain looked newer with metal sprockets. The heads had modern multi-layer gaskets, so did the intake manifold.

The only thing I found that looked 'wrong' is that a few pushrods looked bent? They are suppose to be arrow straight right? I need to measure all of them and see what I come up with.

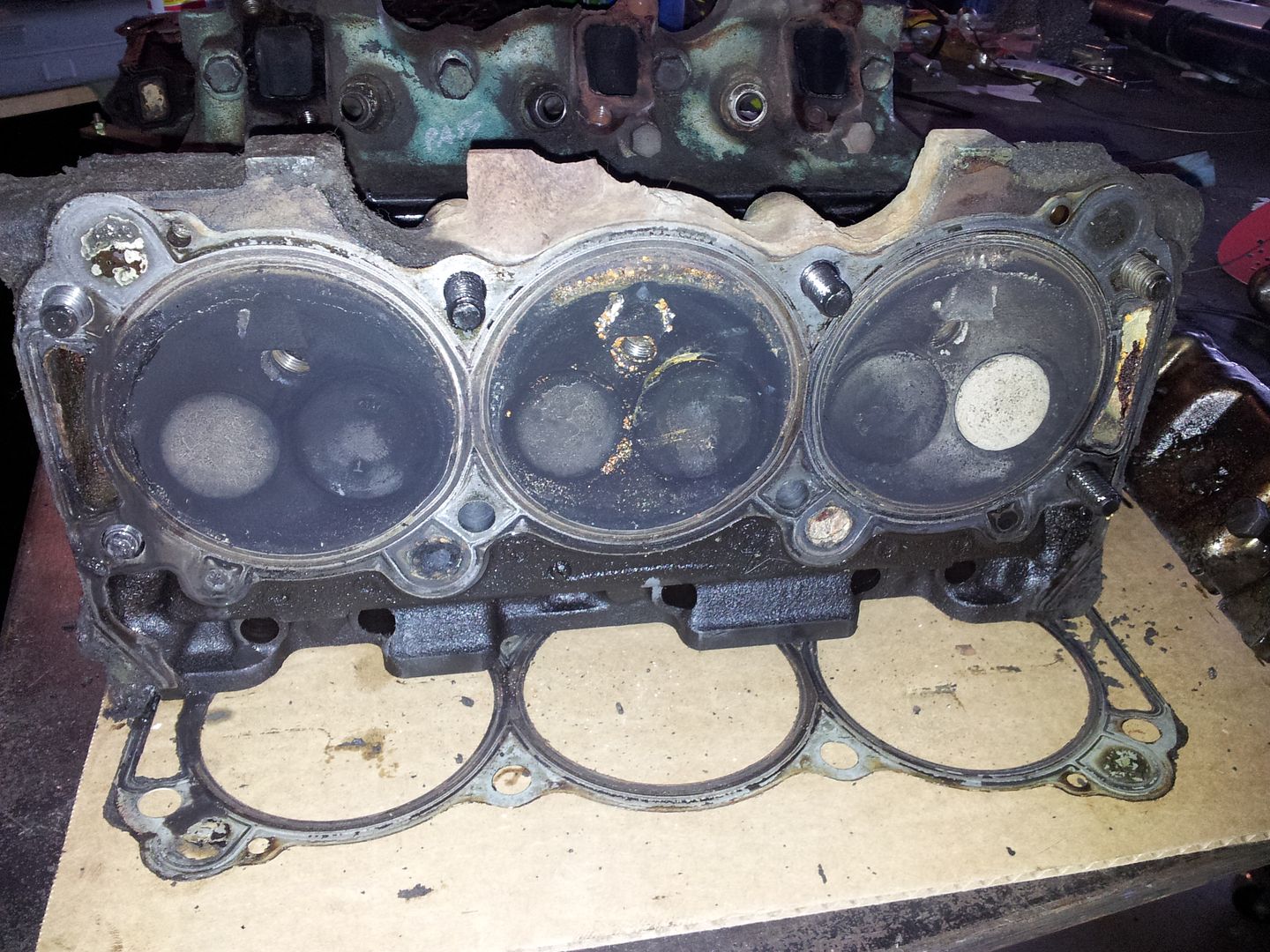

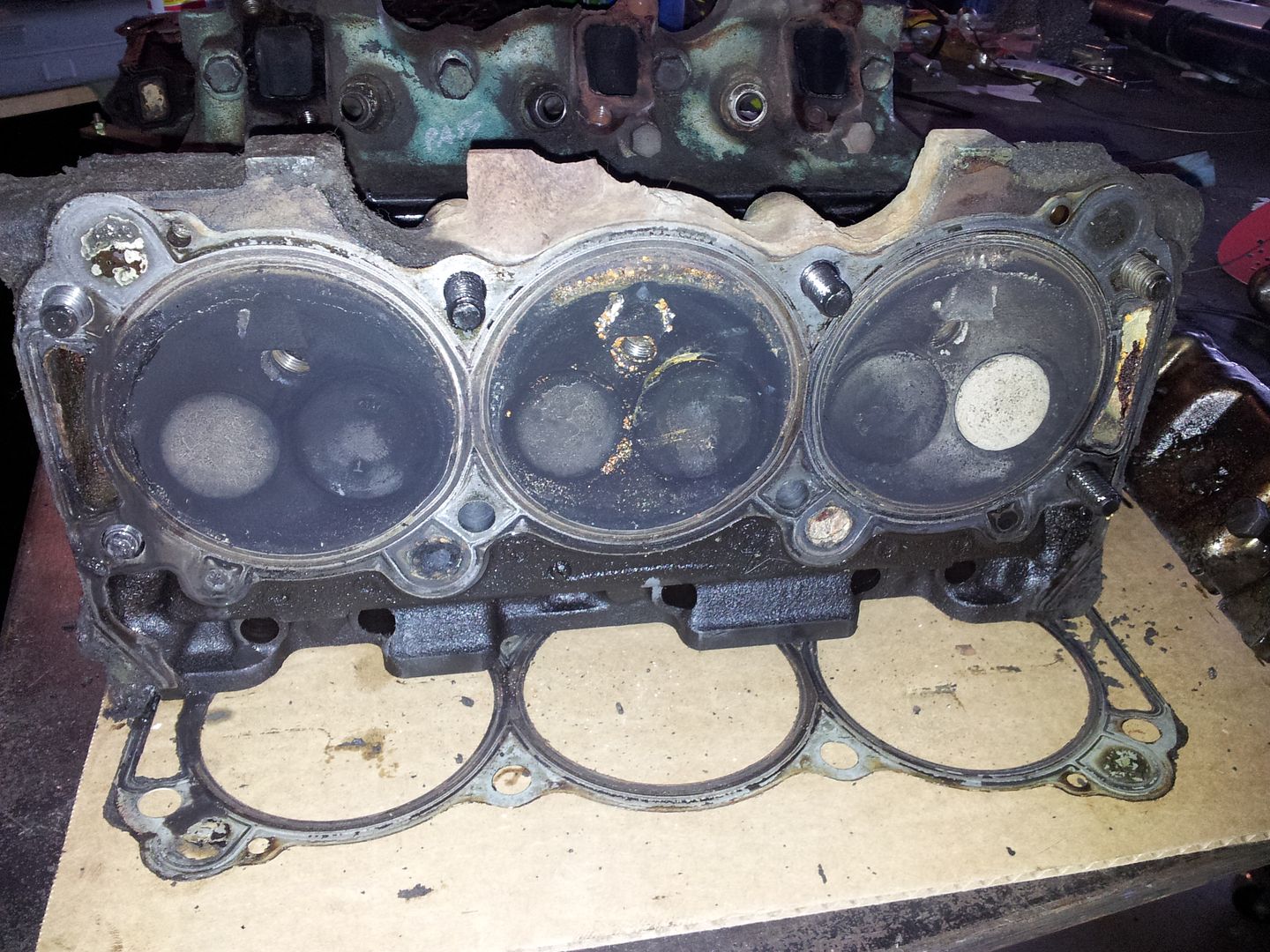

The heads looked pretty good. I need to get something to help take valve spring keepers out so I can inspect the valve seats. Everything looked ok on the heads...maybe a little gunked up but not that bad.

Here are a few more pics....

Plugs. Engine forward to the top.

Water stain on cylinder #4. You can feel just a little something with your finger in that area.

Matching head with #4 in the middle. Maybe a slight head gasket leak?

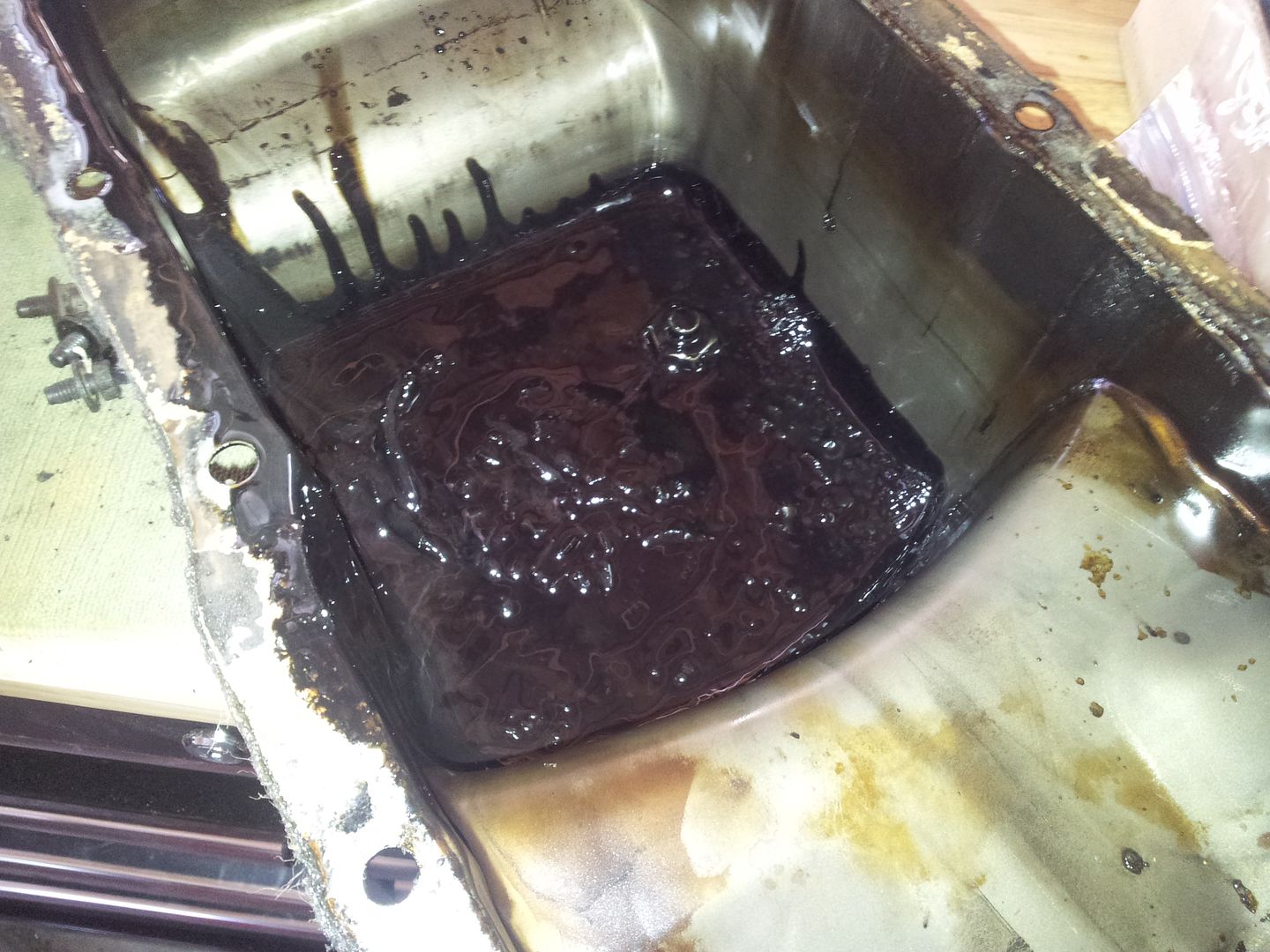

I drained the rest of the oil out of the pan. I will flip the engine over and pull the pan tomorrow night.

So what to do with this engine? The bores look pretty good, maybe run a ball hone down it and stick new rings in it? There is no ridge on the top of the bore so everything should come apart easy. Plastigauge the all the bearings on the bottom end and slip stick in some new bearings? What about the wrist pins? What wears out in there....wrist pin? It looks like the crank needs new seals on each end too? There are modern versions now instead of the rope seals.

Fun stuff.