K2RVR

Adventurer

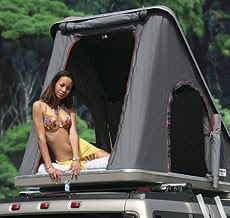

I have the Roof-top-tent (car-top-tent) second generation product in my hands and it is very nice. I think it will compare extremely well with the hannibal and Eazi-Awn, with some aspects being even better.

It is very well thought out and sturdy. the only issues I found are some minor stiching overuns in the changing room, but the tent itself seems very well constructed. Being 300d Ripstop Poly with a PVC coating, it is very durable and dry, but I would recommend seam sealing as you would do with any non-wax fabric or thread.

I know there is some skepticism with a similar but cheaper product, and I agree in many instances. In this case, the quality really impressed me, however. So much so that I decided to become a reseller (in addition to the Oasis line I sell).

I have owned many different Roof Tents and used several more. I still have a loyal fondness for my old canvas Brownchurch RTT, and will probably never let it go, but for winter camping in the brutally wet NW, I think this new tent will be my choice for refuge from the elements and ease of use.

Todd

It is very well thought out and sturdy. the only issues I found are some minor stiching overuns in the changing room, but the tent itself seems very well constructed. Being 300d Ripstop Poly with a PVC coating, it is very durable and dry, but I would recommend seam sealing as you would do with any non-wax fabric or thread.

I know there is some skepticism with a similar but cheaper product, and I agree in many instances. In this case, the quality really impressed me, however. So much so that I decided to become a reseller (in addition to the Oasis line I sell).

I have owned many different Roof Tents and used several more. I still have a loyal fondness for my old canvas Brownchurch RTT, and will probably never let it go, but for winter camping in the brutally wet NW, I think this new tent will be my choice for refuge from the elements and ease of use.

Todd