I spent some time engineering the windows for a successful build. The windows open from the top, the bottom doesn't open.

The windows are cut out of the main body, leaving a 3" flap at the bottom and a generous seam allowance around the opening. This material is offcut, to be used for patching/reinforcement. This allows me to finish the openings by rolling the edge. I designed a 15" dia on the corners to facilitate rolling. Each opening is rolled & ironed before sewing. This turned out better than I expected and I credit that to using canvas. This approach wouldn't be possible with the Vinyl Coated Polyester (VCP) i'm used to.

Each window panel is cut from a different piece of material, again with seam allowances to fold over the edge. Each edge is folded and ironed then the zipper is pinned on. The zipper flap covers the raw edge of the window panel. I sew two seams, one as close to the sipper as I can with a zipper foot, the other at the edge of the sipper flap to capture the raw edge.

The window panels are then pinned back into the main tent body, all around the zipper and lower flap. I start by sewing around the zipper, close to the teeth with a zipper foot. Next is to sew one straight seam at the flap to window panel join. Then I roll the remaining flap over a couple of times to capture the raw edge and add a second seam. Next is to add a faux bar-tack to the edge where the flap is slit on the opening. Final step is to sew the second seam on the zipper.

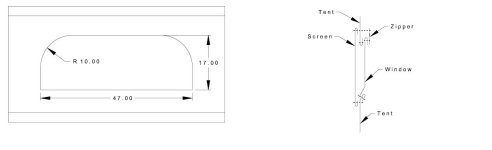

Here's the drawing I made. The radius switched to 15, and there seam diagram on the right has changed. I decided to not try to get the window and the screen on the same seam.

View attachment 844395

-this is as far as I have gotten, the rest is only a plan-

Once all the windows are in the main tent, I will come back and add reinforcing patches where the zippers terminate at the flap. This closes a small hole and will prevent the silt from the flap from migrating.

After patches are in, I'll cut the screens. They will need have the edges rolled, and I may use bias tape and a binder attachment to keep the edge tidy. They will get sewn on the outside.

I acknowledge that this all may not be the best set up for a tent, the selection of cotton canvas being a possible source of mold, etc... But this is the easiest part of the camper build and if I need to make a new tent in a year or two, it's not the end of the world.