You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Skersfan's build for Old Sarge, May 2012...

- Thread starter SWITAWI

- Start date

It is a little stronger than the prototype, and a little heavier, but this is a trailer for staying inside, carrying nice things that makes the off road challenges a little easier. Most would never take this type of a trailer on the toughest trails, it is a large investment, most would protect that investment I think. So I am not as concerned about the weight as I once was. I have drug mine places that under normal circumstances I would not have, but testing and finding out what worked and what did not forces you push the envelope.

I weighed the frame yesterday on my way to have it rhino lined. With 35's, axle, brakes and the spare carrier it came in at 1040 pounds, my guess with water it will hit 23-2500 pounds when finished. Mine loaded when I last weighed it was 2200. And I never had any problem getting it anywhere we took it. It actually got better mileage than my tent trailer due to the sloped front end I think. Mileage on the Kokopelli run was just under 11 mpg, including running around town for a week in Moab. I drive it at 60-65 towing.

On the doors, I bought them directly from Little Guy Tear Drops, so I imagine they are specially made for them. I will research a number on them for you if I can.

I weighed the frame yesterday on my way to have it rhino lined. With 35's, axle, brakes and the spare carrier it came in at 1040 pounds, my guess with water it will hit 23-2500 pounds when finished. Mine loaded when I last weighed it was 2200. And I never had any problem getting it anywhere we took it. It actually got better mileage than my tent trailer due to the sloped front end I think. Mileage on the Kokopelli run was just under 11 mpg, including running around town for a week in Moab. I drive it at 60-65 towing.

On the doors, I bought them directly from Little Guy Tear Drops, so I imagine they are specially made for them. I will research a number on them for you if I can.

Last edited:

theicecreampeople

Adventurer

old sarge is going to be a happy boy ,cant wait to see it in person ....

Bob

I have been and will continue to watch your progress.

thanks

Don

:Wow1:Me too! :drool::wings::lurk::jumping::arabia:

GeoTracker90

Adventurer

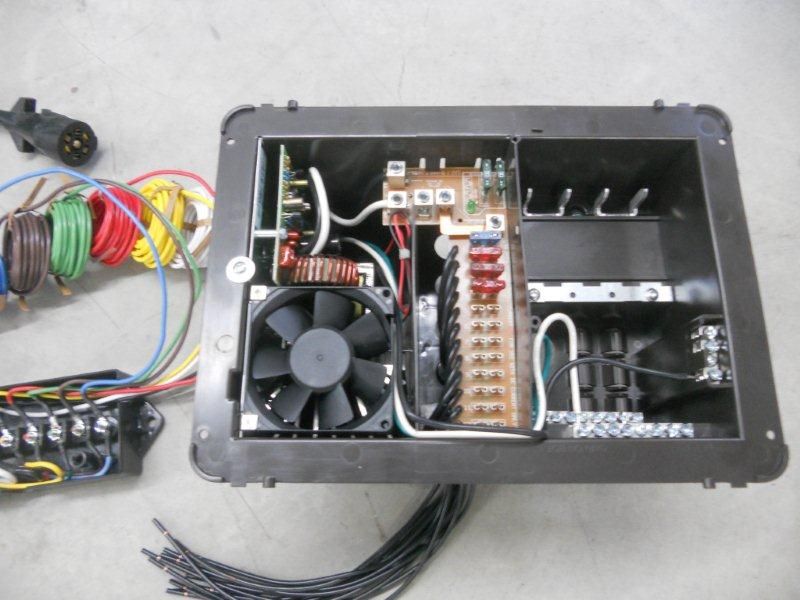

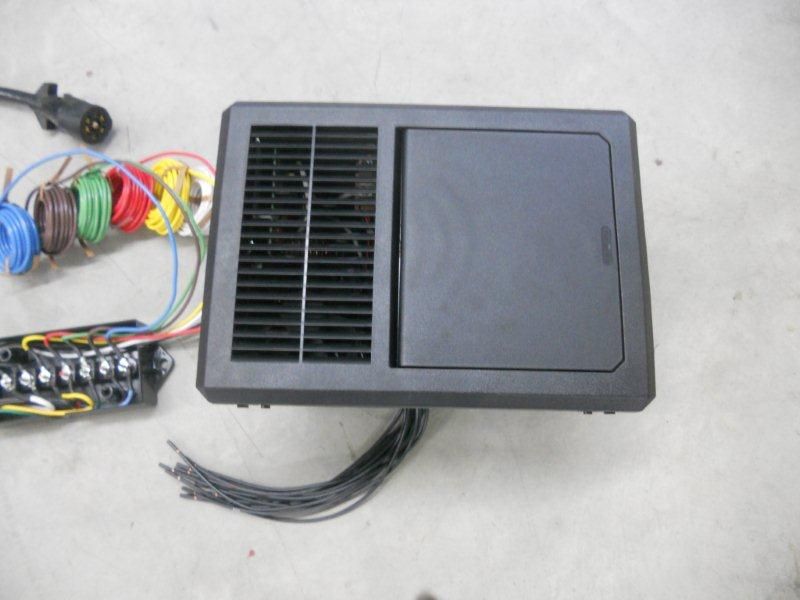

That power box with the fuses, fan, etc. looks very nice. Do you have a link to a vendor for it?

Thanks,

Mike

Thanks,

Mike

SWITAWI

Doesn't Get Out Enough

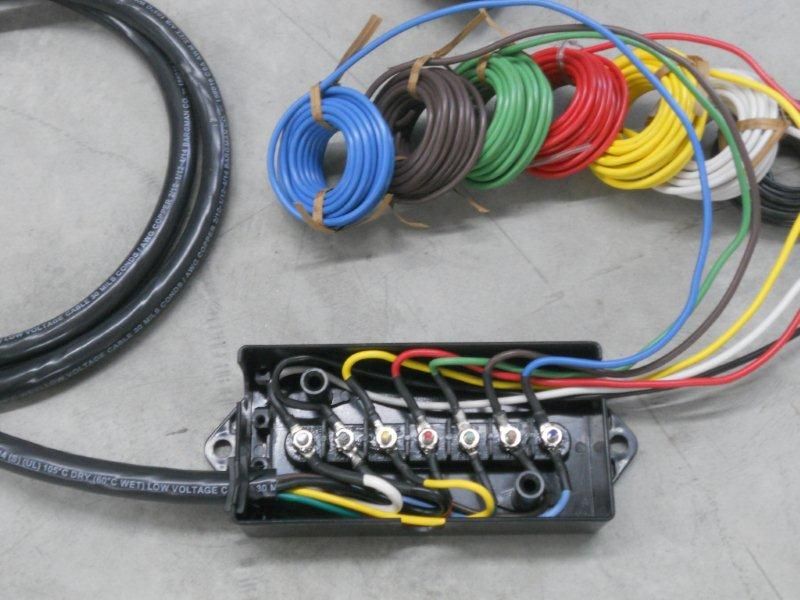

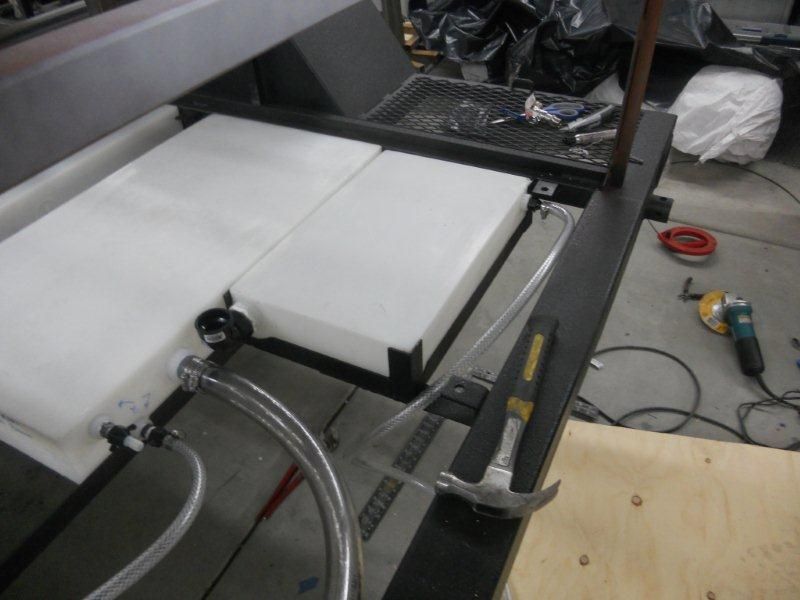

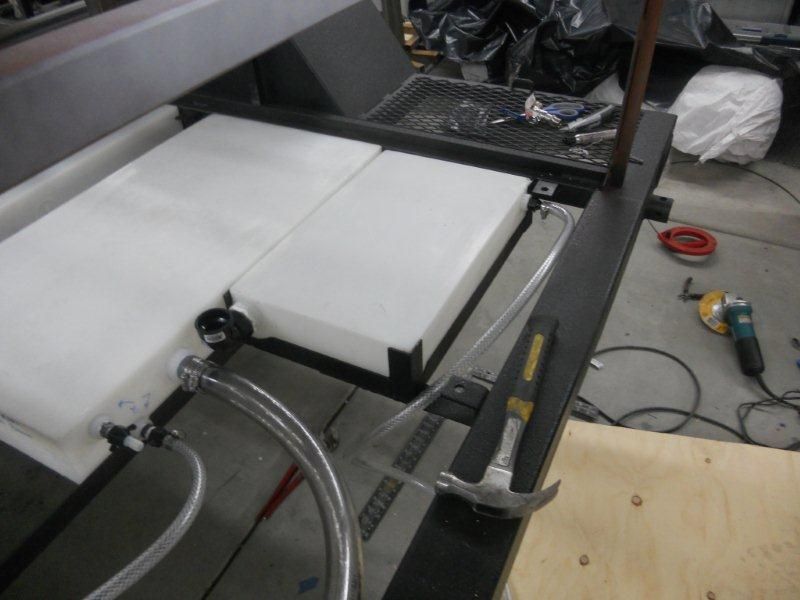

06/09... "Here are a couple of pictures, I forgot to take pictures of the set up in the bumper. I welded a bolt to the top of the 4"x4" on the inside, this way the ground will always be dry and out of water or rust that develops on the inside, also all wiring was soldered. I used crimp type, split them, but crimped and then soldered over them.

The Plywood is marine grade with water seal on it. Then I take 8mil black plastic and cover the bottom, after that I will run a heavy bead of construction-grade black silicone around the base, sealing water out from the bottom, then I will cover the top with black plastic and aluminum insulation, that will be last before installing the mattress. The silicone will be placed in the little troughs made with angle iron to see the water out from the outside.

Will send a couple more pictures shortly. - Bob"

The Plywood is marine grade with water seal on it. Then I take 8mil black plastic and cover the bottom, after that I will run a heavy bead of construction-grade black silicone around the base, sealing water out from the bottom, then I will cover the top with black plastic and aluminum insulation, that will be last before installing the mattress. The silicone will be placed in the little troughs made with angle iron to see the water out from the outside.

Will send a couple more pictures shortly. - Bob"

hollaback55

Explorer

i didn't see the 7 pin wiring and junction box setup on either website. did you buy that as well or make it yourself?

Aspen Trails Trailers

Supporting Sponsor

I bought the box at Fleet Metal Box truck outfitters in Colton, California, they make my metal boxes for this trailer and the box trailer I build.

But the name on the box is Phoenix USA, Inc, Cookeville, TN.

Hope that helps

Bob

But the name on the box is Phoenix USA, Inc, Cookeville, TN.

Hope that helps

Bob

SWITAWI

Doesn't Get Out Enough

More progress and pictures...

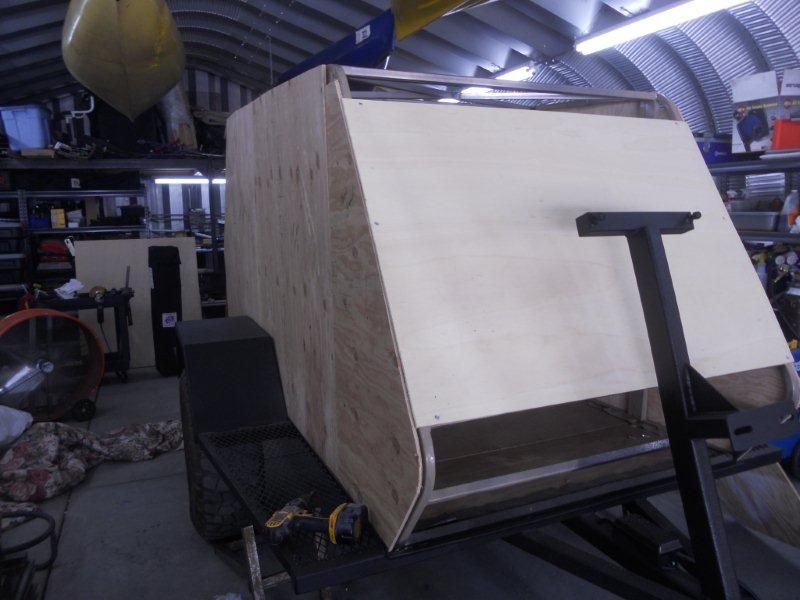

Pictures show some progress, walls temporarily up for cutting and fitting. The board in the middle of the trailer covers the wiring system, all openings will be covered with this plain sanded board. I will stain it when I am done and then seal it in. I have found a thin plastic seal sheet that is waterproof. The side walls in the galley area will have it on if I can get it to fit, not much room in the trough that it sets in on the side.

Working on the back door, setting locks and putting in gas struts to keep the back door up. Cannot find the ones I used on my prototype, so I will have to go shop for them today. Have not received the ARB fridge slider, which is not a bad thing. I discovered that I will need to make a bracket for it as I can no longer drill through the floor now that the gray water tank is there. And the learning process goes on... Not a big deal but I just realized it would make a change to the inside compartment as well as the under flooring setup.

I will continue to work on the siding, the small filler box fronts and possibly the wiring today. Will find the struts and get the back door done by tonight hopefully. I have to pick up the accessories box, so I'll do that when I pick up the glass.

Got a lot done yesterday and this morning, moving at a good pace. Still

looking for outside lights, not easy to find. - Bob

Pictures show some progress, walls temporarily up for cutting and fitting. The board in the middle of the trailer covers the wiring system, all openings will be covered with this plain sanded board. I will stain it when I am done and then seal it in. I have found a thin plastic seal sheet that is waterproof. The side walls in the galley area will have it on if I can get it to fit, not much room in the trough that it sets in on the side.

Working on the back door, setting locks and putting in gas struts to keep the back door up. Cannot find the ones I used on my prototype, so I will have to go shop for them today. Have not received the ARB fridge slider, which is not a bad thing. I discovered that I will need to make a bracket for it as I can no longer drill through the floor now that the gray water tank is there. And the learning process goes on... Not a big deal but I just realized it would make a change to the inside compartment as well as the under flooring setup.

I will continue to work on the siding, the small filler box fronts and possibly the wiring today. Will find the struts and get the back door done by tonight hopefully. I have to pick up the accessories box, so I'll do that when I pick up the glass.

Got a lot done yesterday and this morning, moving at a good pace. Still

looking for outside lights, not easy to find. - Bob

SWITAWI

Doesn't Get Out Enough

These are pictures of the walls being attached for fitting, they are not permanent and will be removed to do wiring and have light in the trailer. Will rough in one of the doors possibly yet today, but need to get the rear struts figured out, so need to drive to town.

Once I am ready to attach the walls, they will get a #10x1" self-tapping screw every 10in around the outside of the trailer, then the same on all uprights and horizontal runs about every 15in. Around the doors, I do not attach the door itself this was as it has more than enough to make it solid and sealed. When the glass goes on the system is used for the outer rim, but alternating so none are on top of each other. I will also run screws into the fender wells to attach the uprights when the fiber glass is on. Those will not be visible, but it just makes me feel better about the seal on the trailer. All joints of the plywood will be siliconed under and between the junctions, making the trailer as water-resistant and airtight as possible.

I have realized that I have made a huge mistake, welding the spare carrier in place already is going to make installing the window a huge pain in the ********. I will have to jig saw it in where I normally just router it in. Oh well that is what you get for thinking out of the box.

I will try to get the barrier wall in this afternoon, but I wanted to get walls up to stop the overspray from the kitchen and side walls. All have been painted on the outside and now just the inside and top remain. The top will be the last to go on as I need light to do the wiring and soldering.

Moving at a good pace, but doing everything I can think of to make this the soundest Alaskan trip trailer ever. - Bob

Once I am ready to attach the walls, they will get a #10x1" self-tapping screw every 10in around the outside of the trailer, then the same on all uprights and horizontal runs about every 15in. Around the doors, I do not attach the door itself this was as it has more than enough to make it solid and sealed. When the glass goes on the system is used for the outer rim, but alternating so none are on top of each other. I will also run screws into the fender wells to attach the uprights when the fiber glass is on. Those will not be visible, but it just makes me feel better about the seal on the trailer. All joints of the plywood will be siliconed under and between the junctions, making the trailer as water-resistant and airtight as possible.

I have realized that I have made a huge mistake, welding the spare carrier in place already is going to make installing the window a huge pain in the ********. I will have to jig saw it in where I normally just router it in. Oh well that is what you get for thinking out of the box.

I will try to get the barrier wall in this afternoon, but I wanted to get walls up to stop the overspray from the kitchen and side walls. All have been painted on the outside and now just the inside and top remain. The top will be the last to go on as I need light to do the wiring and soldering.

Moving at a good pace, but doing everything I can think of to make this the soundest Alaskan trip trailer ever. - Bob

Last edited:

SWITAWI

Doesn't Get Out Enough

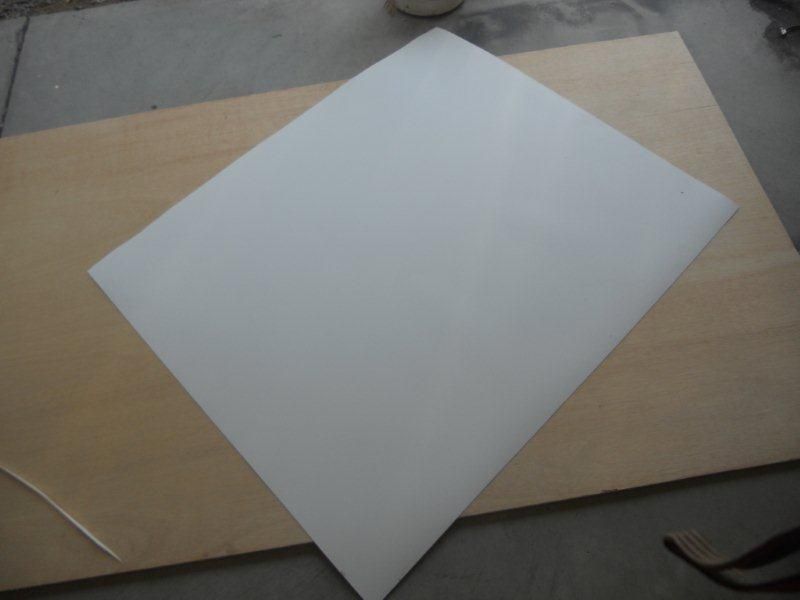

Well this really looks nice, and will make keeping the kitchen clean easier. It is water proof and supposed to be fire retardant. One thing it does is increase time on the build. I had to spray it with 3M 90 grade contact cement then wait one hour for it to dry, trim it, and then stick it on the trailer. I have not sawed through it or used a router on it yet, that will be the extreme test of whether I use it as a regular part of the trailer or not.

Again this was not on the prototype, and this is just another step to make it better than what I had in mind originally. My concern is the trough for the walls. It adds about a 16th of an inch so I may have to do some grinding to get the fiberglass to slip in. Can work around that on the next trailer, but this one is the guinea pig so to speak. I hope it fits and works out as it does make the kitchen look much nicer.

I will let it dry a little longer then cut away the excess and see what happens. - Bob

Again this was not on the prototype, and this is just another step to make it better than what I had in mind originally. My concern is the trough for the walls. It adds about a 16th of an inch so I may have to do some grinding to get the fiberglass to slip in. Can work around that on the next trailer, but this one is the guinea pig so to speak. I hope it fits and works out as it does make the kitchen look much nicer.

I will let it dry a little longer then cut away the excess and see what happens. - Bob

Similar threads

- Replies

- 65

- Views

- 7K

- Replies

- 18

- Views

- 3K

- Replies

- 4

- Views

- 1K

- Replies

- 6

- Views

- 3K