luthj

Engineer In Residence

I don't think any suburban came with 1410 ujoints and I think only the 2500hd and up trucks came with 1410 on the rear shaft only. Worth a double check on that.

You are probably right. I wast doing a few googles trying to roughly estimate driveline torque. I do need to work out what GM used on the front, but thats a ways down the road at this point.

Just curious, what Factor of Safety are you using for the subframe and other fab parts that will see dynamic loads?

Honestly I am not sure yet. The issue with dynamic loads on a vehicle are their unpredictability. Especially with regards to shock loading. Thankfully the tires and wheels serve as buffers, bending or deforming to absorb energy. Same goes for suspension bushings.

Right now I am going to simulate worst case loading. Such a single wheel catching a rock/curb during a lateral slide, hitting a curb at speed, etc. From there I am looking for a FOS of at least 1.5 for these. For cyclic loading, like shock towers, etc. I would use FOS of 2 as the minimum value. The endurance limit for steel is usually about half the ultimate tensile strength, so staying above 2 takes fatigue failure mostly out of the picture.

Other worst case scenarios would be a bogged recovery using on lower A-arm, dropping the subframe on a rock, and jacking from one of the cross-overs.

I am more accustomed to working with aluminum, which has no fatigue/endurance limit, and has much lower toughness. Steel is so much more forgiving, as it can absorb so much more energy in deformation, and still carry a load.

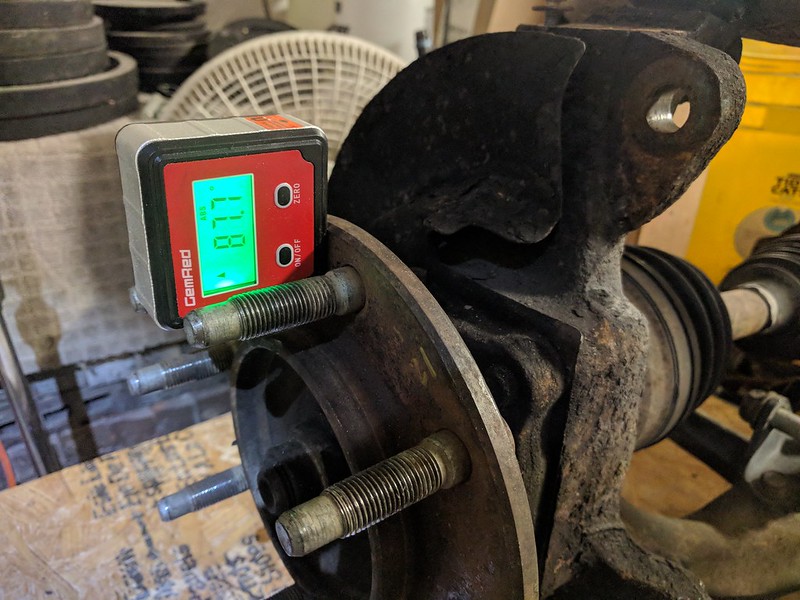

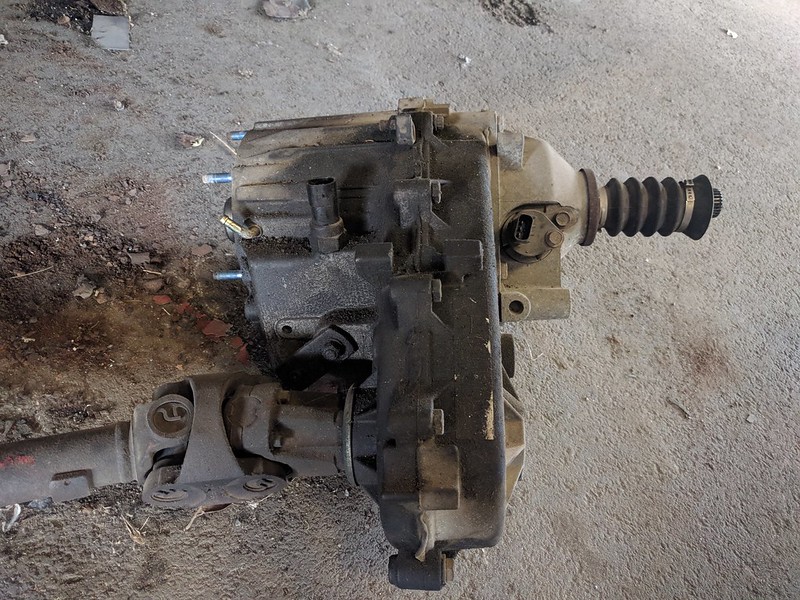

IMG_20190123_144721

IMG_20190123_144721 IMG_20190123_144620

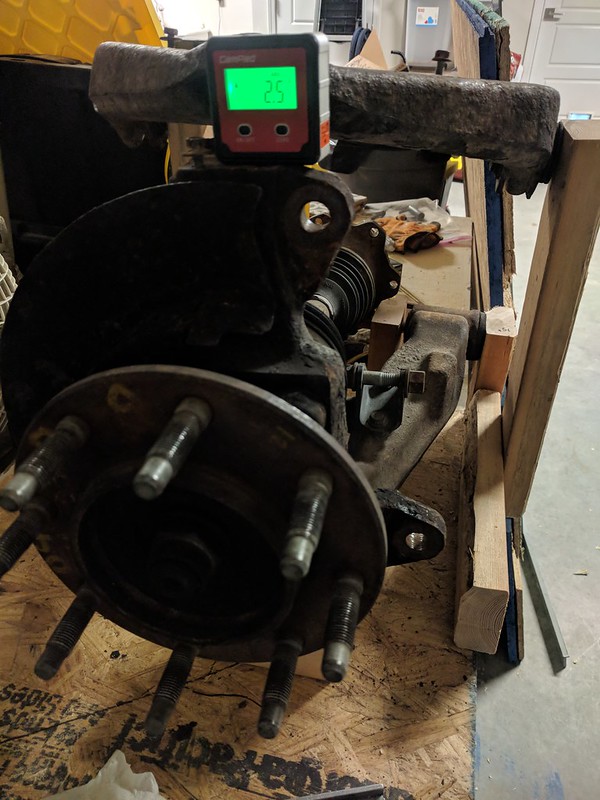

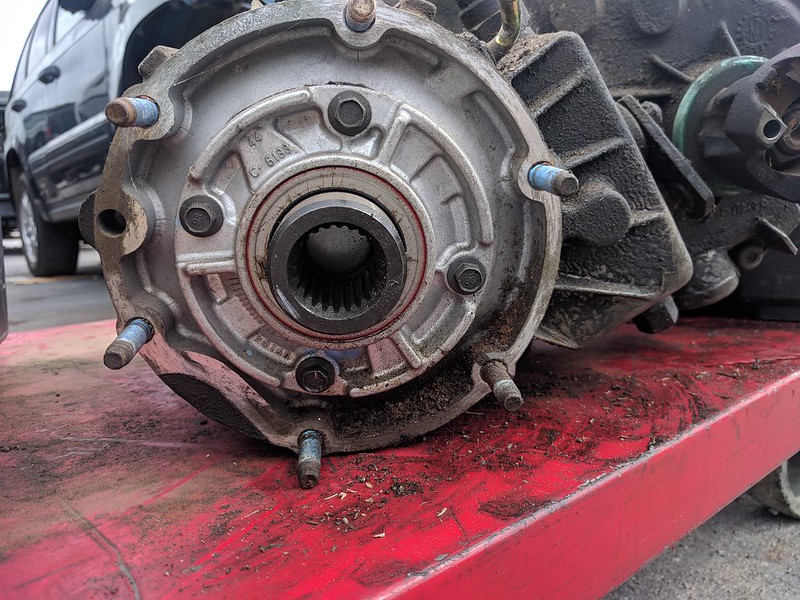

IMG_20190123_144620 IMG_20190123_145112

IMG_20190123_145112 IMG_20190123_145133

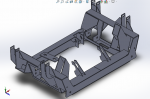

IMG_20190123_145133

IMG_20180903_095638

IMG_20180903_095638 IMG_20180903_110413

IMG_20180903_110413 IMG_20180907_182606

IMG_20180907_182606