StumpXJ

SE Expedition Society

wow! i just read through the whole thread and i have to say great build! i especially love your dash set up. great work on the xj. Ive always secretly loved the XJ platform, (Dont tell my chevy loving friends lol)

i just wanted to ask you about your camera system. any details on it? how many cameras do you have? what areas of the vehicle do you watch with them?

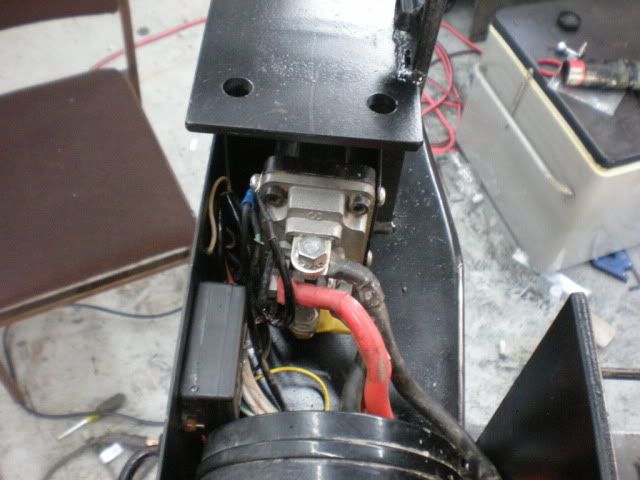

I have a front and rear camera. I LOVE using them on the trail. It makes turning around in tight areas MUCH easier. Backing up to a trailer? No problem... I got everything off of ebay a few years ago, and its super simple to hook up. Nothing special.

This is an awesome XJ and has lots of the stuff I want to do to my own in it!

I'm wondering about your laptop mount- if you had a manual tranny could you still shift with it? I have the same laptop and am trying to figure out how I'll be mounting it in the vehicle. Interested in making one for sale?

I have honestly never driven an XJ with a manual, so I am not sure how much throw there is in the shifter. I cant help with the exact questions, but I feel pretty confident it could be fairly easily modified to make it work. Not really interested in making one for sale honestly. Too much time in it to make it worth my while. It would cost a LOT... and its just a hobby for me. Usually when I start charging folks for things its not fun anymore. If you are local, we could fab something up over a weekend for the cost of materials, just as an excuse to get out in the shop.

Thanks for the compliments.

Let me know if I can help.

I have wheeled with stump and this rig is just amazing....BTW that newcastle looked yummy..:drool:

Somebody say Newcastle?

Nectar of the gods for sure. :beer:

~ Stump