..

CONTINUED FROM PREVIOUS POST

********************************************

4. Making the TerraLiner's generators movable

********************************************

The generator itself would be mounted on a secondary tray that would slide off the cargo tray, and onto the load-bed of a pick-up truck. How best to do this is an open question. What's wanted is to keep the bottom of the generator as close as possible to floor of the side-locker, and we will have already added 2 - 3 cm of height to account for the cargo tray. So adding even just another 5 or 10 cm of height for wheels located directly underneath the generator, as per a low-rise dolly cart, is still 5 to 10 cm too much:

Instead, what seems to be wanted is a dolly cart where the wheels are located to the sides. Sure, this will increase the length of the compartment that stores the generators from 1.4 m to 1.6 m or thereabouts. But better to increase the length than the height. Here I have in mind a miniature version of something called a "Low-Boy" trailer, the kind of semi-trailer used to move heavy, oversized cargo. In this trailer the load bed drops down very close to the ground between wheels at the front and the back -- see

https://en.wikipedia.org/wiki/Lowboy_(trailer) and

http://flickrhivemind.net/Tags/camion,heavyhauler/Interesting . So far I have been able to find only one decent image of this idea "miniaturized" in the form of a dolly cart; it's the first image below:

A much simpler solution might be to permanently mount (i.e. weld) the generator to a something known as a "

pallet truck" -- see

https://en.wikipedia.org/wiki/Pallet_jack and

pallet truck . These are available in very low-profile versions that again would not add much height to the generator -- see

http://vestilmfg.com/products/mhequip/pallet_truck.htm ,

http://vestilmfg.com/products/mhequip/pt-lowprofile.htm , and

low profile pallet truck . When the piston is depressurized, the backs of these trucks sit directly on the floor without wheels, and if they are carrying a heavy load, they are impossible to move. But the piston is easily pressurized by pumping the handle up and down, which would be easy to do once the cargo tray carrying the generator has been pulled out of the TerraLiner. When the piston rises it lifts the back of the pallet truck so that it no longer sits on the floor, the back rotating wheel becomes engaged, and the load becomes mobile. One can move

very heavy loads using a pallet truck: loads in the range of 2000 - 4000 lbs using the smaller, manual versions, and much heavier loads with larger and more automated versions. Very small wheels or roller ball-bearings are located underneath the fronts of the two forks:

The "super-low-profile" version made by Vestil is just 1.5 inches high when lowered, so it would add only 3.8 cm to the overall height of the generator when stored inside the TerraLiner -- see

http://www.vestildocs.com/drawings/PM2-2044-SLP.pdf and

http://www.vestildocs.com/drawings/PM2-2044-SLP.pdf.

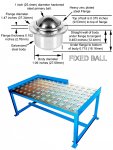

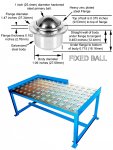

Yet another solution might be to embed roller ball-bearings to the underside of the secondary tray that carries the generator. Here the most common application is something known as a "ball transfer table" -- see

https://en.wikipedia.org/wiki/Ball_transfer_unit ,

http://www.lewcoinc.com/conveyors/products/ball-table.aspx ,

http://www.globalindustrial.com/c/material-handling/conveyors/ball-transfer ,

http://www.directindustry.com/cat/c...its-ball-transfer-table-ball-bars-BD-803.html ,

http://www.balltable.co.uk ,

http://www.omnitrack.co.uk ,

http://www.ashlandconveyor.com/categories/ball-transfer , and

http://www.ashlandconveyor.com/categories/ball-transfer/ball-transfer-ball-transfer-tables :

So imagine a ball transfer table reversed, rotated "upside down", and permanently affixed to the underside of the generator.

Or, some combination of the above three solutions might make it possible to add at most 1 cm to the height of the generator, while even still rendering it completely mobile, just as long as it's traveling on a relatively smooth metal or asphalt surface or similar, e.g. the concrete floor of an auto repair shop. Assuming that the bottom of a WhisperPower MGV-200 generator is sufficiently load-carrying, wheels or roller ball-bearings could be welded to one end, so that only 1 cm of ground clearance is left underneath the generator itself; and a pallet truck rotating wheel + piston could be welded to the other end. So in effect we could construct a "

low-boy pallet truck" by custom-fitting the important bits to

ends of the generator housing, as opposed to affixing anything underneath it.

The goal in all of this is to keep the height added to the generator down to the absolute minimum possible, while still allowing the generator to be easily removable because it has wheels or roller ball bearings somehow attached; and is in turn sitting on a cargo tray that can be pulled out of the TerraLiner.

********************************************

5. Providing unprecedented engine access and service flexibility

********************************************

Now the main reason why one would want to mount a generator on a slide-out cargo tray in the first place, is because that way one might have 360-degree access with the engine remaining

in situ. The TerraLiner's generators will be its engines. So in effect mounting the generators on slide-out cargo trays provides 360-degree engine access for a mechanic, something that few (or perhaps no?) currently available motorhomes provide. This is actually one of the better arguments for the Class-C format of motorhome: that because it is built on a CBE truck that has a bonnet, engine access is simply a matter of popping the bonnet. The following video is not professionally made, and most of his arguments against the Class A format can be easily addressed via intelligent design:

But his argument about engine access is an important one, and deserves to be taking seriously.

Premium-luxury class motorhomes solve the engine-access problem by relocating the engine to the back of the coach. In this video his comparison is a bit unfair, because he only contrasts a Class C with a down-market Class A that still has the engine located up front. Whereas more up-market class A motorhomes are usually full integrated "pushers", with the engine mounted in back, where a very large panel at the rear of the coach provides much better access. But placing the engine in the rear would make it impossible for the TerraLiner to have a rear deck, as per the Wothahellizat 1 and 2. So that's why a hybrid drive-train is quite a gift, from a design point of view. It allows placing the TerraLiner's ICE-driven generators on the sides of the vehicle, instead of the front or the back. By doing so, in the front we eliminate the engine-tunnel that would have made a flat-floor cab difficult, or even impossible; and in the back, there is no engine to block the possibility of rear deck. Furthermore, with the generators mounted on slide-out cargo trays, engine access will actually be superior to any motorhome format developed thus far, including pop-the-hood CBE.

However, here I am suggesting that things could be taken one step further. Not only should the TerraLiner's generators slide out on cargo trays, but those cargo trays should be designed such that they can "change altitude" easily, and removing the generators completely for transport on the back of a pick-up truck will prove relatively simple.

Logistically speaking, this would allow the TerraLiner's generators to be serviced and/or repaired separate from the vehicle itself. The TerraLiner could continue to camp in a beautiful spot, recharging its batteries periodically using just one generator, while the other generator is off at the Steyr service depot, or at a marina that knows how to repair a marine generator. In the case of a turbine APU, the servicing and/or repair would take place at an airport. The TerraLiner itself would not need be parked at a marina or an airport while one of its generators was being repaired. The pick-up truck could be locally rented, or provided by the shop that does the repair.

********************************************

6. Service and Repair of the TerraLiner's Electric Drive-Train: Using Tesla's Emergent Global Network?

********************************************

Of course, the electrical side of things is another story. But there too, if the entire electrical portion of the drive-train was Tesla technology, including the electric motors, then perhaps the TerraLiner would have access to Tesla's fast-growing international network of service centers. By 2020 Tesla should have service centers throughout China and Japan, and perhaps soon thereafter throughout Latin America. Although global

cars exist -- cars that are sold in almost every country worldwide, and that can be serviced just about anywhere -- the same is not true for trucks. There is no such thing as a truly global truck, whereas certain car companies have established distribution and service networks that are fairly universal, for instance, Mercedes. And presumably Tesla will want to do the same.

In short, if Tesla were responsible for all of the TerraLiner's electric drive-train technology, and if Tesla continues its meteoric rise as a car company, and expands into markets where it is currently not present (e.g. South America, the Middle East, most of Asia), then the TerraLiner could tap into what will soon become a truly global service network for electric vehicles.

So far Tesla has mainly an American phenomenon, only selling its first car in Europe in 2013 -- see

http://marketrealist.com/2015/08/investors-guide-tesla-motors/comments . And at present, Tesla seems to have mainly an American and European presence -- see

http://www.fool.com/investing/gener...rs-incs-international-expansion-to-hit-1.aspx. But Tesla has plans to massively expand into China, and to expand massively, period -- see

http://www.ft.com/cms/s/0/aec36734-18f3-11e4-80da-00144feabdc0.html#axzz3zhp2sD1L ,

http://www.telegraph.co.uk/finance/...e-500m-to-fund-ambitious-expansion-plans.html ,

http://www.fool.com/investing/gener...-not-tesla-is-expanding-across-the-globe.aspx , and

http://www.autonews.com/article/201...ns-will-stretch-tesla-beyond-its-comfort-zone :

And so it does seem plausible that the network of Tesla service centers may become truly global over the next 10 years.

Again, because all drive-line elements in the TerrraLiner will be fail-safe redundant, even if a Tesla, Steyr, or Boeing service center is not right around the corner, the TerraLiner will be able to drive the extra 1000 or 2000 km that might be required to get to the nearest Tesla depot, marina that services generators, or international airport that services jets.

********************************************

7. How the use of car-sized modular components in hybrid trucks may change the service/repair landscape

********************************************

As a transportation design specialist, what then interests me is how the electrification of the world's fleet of cars and trucks may have a profound effect on how automotive and truck service centers function.

In the world of traditional mechanical drivetrains, differently sized vehicles need to be serviced in different kinds of shops, not just because trucks are much bigger than cars, but also because their engines and transmissions are much bigger and different, too. Whereas in the world of electric drive-trains, even in a very large vehicle such as the TerraLiner the electrical components can be individually much smaller. The same electric motors used in a Tesla sports car, for instance, just need to be multiplied by three. Indeed, perhaps

all of the electrical elements of the TerraLiner's drive-train and its controlling software might be identical to those found in a Tesla...?

Maybe I am wrong about this; but it would be very interesting if I were right. Of course there would still be the issue of vehicular size. But I wonder if the Terraliner could be designed in such a way that any Tesla service center could diagnose, repair, and/or replace its electric motors and other electrical components, without the TerraLiner needing to actually enter a covered shop?

I wonder if anyone has written about how driveline "modularity" in a serial hybrid truck may radically change the service landscape available for such a vehicle, because all of its components will be car-sized, instead of truck-sized?

The above is just a very rough sketch as to how TerraLiner servicing and/or repair might occur. It's merely preliminary, but it may be useful because it suggests that contrary to one's initial assumptions, a hybrid TerraLiner may actually prove

more globally serviceable than, say, a more ordinary kind of MAN TGS truck. The Steyr motor used in the WhisperPower generators, for instance, is basically a small-car motor, not a truck motor. So it stands to reason that it should be more widely repairable. And the same will be true of the TerraLiner's electrical components, if Tesla does in fact create a truly global service network, and the TerraLiner could use it.

All of this has gotten me thinking: how

do large Class A motorhomes get serviced in the United States? It must be a bit awkward for a full-timing couple if their motorhome's engine or transmission needs 2 or 3 days' of service, and hence, they have to leave their

home and not just their vehicle with the auto mechanic. On web-forums some Class A motorhome owners write that they just continue living in their motorhome in the parking lot of the auto shop, while it was being serviced or repaired. However, what I am imagining above is a more "modular" approach, an approach that might cut down on the number of days that the TerraLiner's owners need to camp in such parking lots. If instead the TerraLiner's generators were easily and completely removable, then the TerraLiner's owners could continue camping in their mobile home on farmland, while one of the "engines" -- i.e. one of the diesel generators, or a turbine APU -- gets fixed at an auto shop, or at an airport's APU service depot.

********************************************

8. Servicing Camper Box Systems

********************************************

Of course, servicing the camper box systems of the TerraLiner would be another matter, but no different from servicing an ordinary, mainstream Class A. Like all large motorhomes the TerraLiner would want to check into speciality "Motorhome service centers" from time to time -- see

http://www.approvedworkshops.co.uk/approved-touring-caravan-motorhome-servicing and

http://www.approvedworkshops.co.uk/search/ for the UK, for instance, and for the United States, see

http://www.rvservicelink.com ,

http://www.funroads.com/coachcare/ , and

http://www.funroads.com/rv-repair/ . Motorhome-specailized service centers are abundant in First-World countries, rare in Second-World countries, and pretty much non-existent in Third-World countries. In this respect the TerraLiner's camper box will be no worse off than any other motorhome. All of them need to be relatively autonomous, reliable, and hassle-free when traveling in Third-World countries.

But the good thing is that the camper box systems are not as "mission critical" as the generators, the electric motors, and the electrical system that delivers power from the generators to the motors. The electrical motors will be redundant. So presumably if one electric motor fails, the TerraLiner will sill have two running, and will be able to drive to the nearest Tesla depot.

********************************************

9. The TerraLiner: Innovative, but not Sci-Fi, and designed to use "off the shelf", reliable, proven technologies, combined in a new way

********************************************

In any case, "serviceability" is a critically important question, which is why I discussed it at length. So even though innovative ICE technologies are fascinating, what continues to interest me most is finding more manufacturers of tried-and-tested diesel generators intended for use on yachts, i.e. more manufacturers like WhisperPower.

A while back in the thread the TerraLiner was specified as vehicle that should be made from components that are "off the shelf" and ready-to hand. The TerraLiner will simply combine those components in new ways. In other words, the TerraLiner will be innovative, but not Sci-Fi. Hence, the TerraLiner will not require constructing a completely new ICE from scratch, and not even a Gen-Set. Rather, the TerraLiner will want to use two diesel Gen-Sets, or one diesel Gen-Set + a turbine APU, that are proven, reliable technology, and that could be serviced and/or repaired worldwide. If what I have written above in this posting series is at all reasonable, then there is some chance that a serial hybrid TerraLiner might actually prove

more serviceable worldwide than a typical MAN TGS or Mercedes Actros truck, not less. Even though the TerraLiner will be a hybrid, that does not automatically mean that it will be a service and repair nightmare. So if this possibility exists, then the last thing one would want to do is undermine this possibility by having the TerraLiner use a still somewhat experimental ICE as the motor powering its primary generator.

In short

Silverado, although cutting-edge developments in ICE technology are interesting, they won't really apply to the TerraLiner, at least not unless they get bundled with a generator to create a comparatively lightweight and reliable package, such as the MGV-200 by Whisperpower; a generator package that has been on the market long enough, such that it could be serviced and repaired just about anywhere.

Again, to summarize: think "innovative", but not "experimental" or "Sci Fi". Think "off the shelf", proven, reliable technologies, brought together and combined in a new way, a way that will make a new form of global motorhoming possible.

All best wishes,

Biotect