Mwilliamshs

Explorer

Thanks for the videos. Fun and interesting to watch the susp work.

are we to accept that those videos are of the same "lower in the travel range" setup seen in MGM's pictures?

Get your tickets to THE BIG THING 2026!

Thanks for the videos. Fun and interesting to watch the susp work.

Agile does box their radius arms where they meet the axle housing. Looks like an "L" if I remember right. They also have the lower tube kind of pinched over the bottom of the "L"

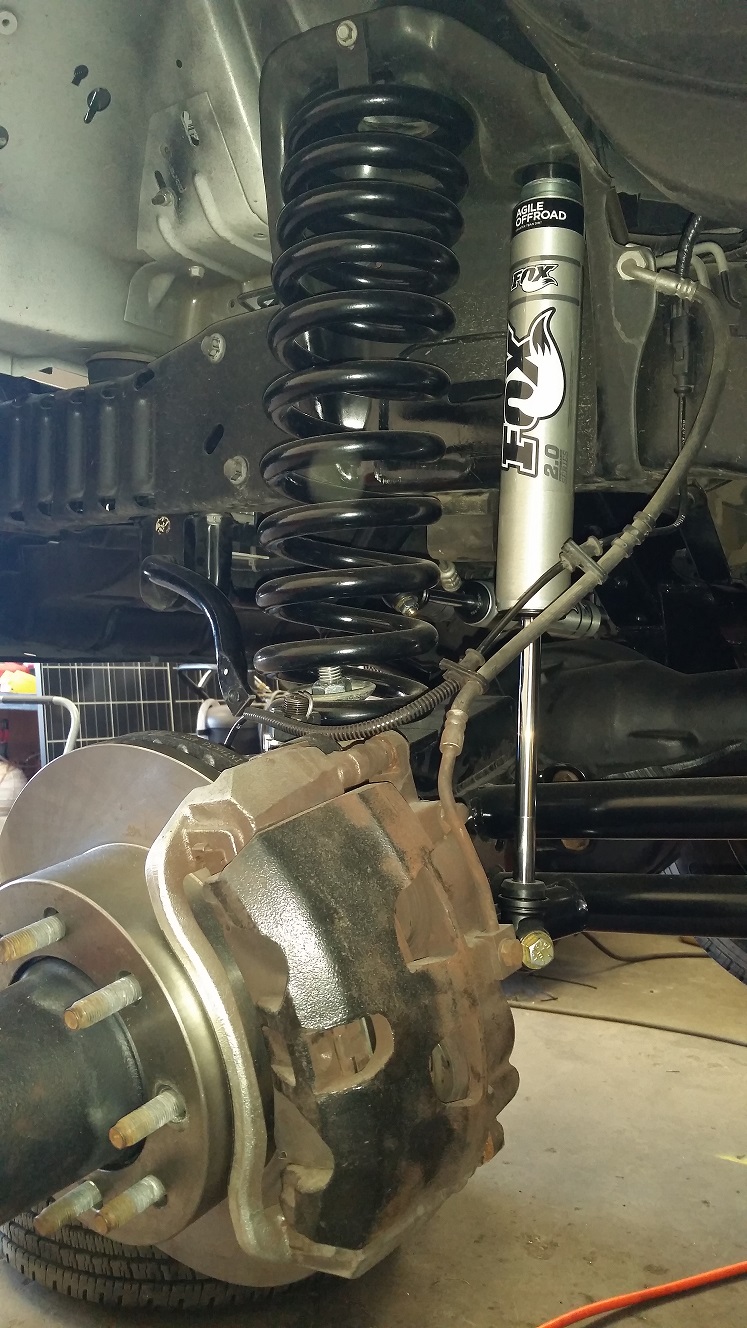

You can kind of see here where the lower tube sticks out below the axle housing in this screen grab...

I'm planning on gussets on my arms when I get to that point

Sent via flux capacitor

You just need to remember that a TTB suspension is basically two levers that pivot at one end with the wheel at the other end. Both the bumpstop and shock are at mid-points on the lever... If the lever (axle beam) is able to move up say, 3" where it hits the bumpstop, the wheel (at the end of the beam) can move up maybe 5". So it's definitely possible there's 5" of uptravel, and 7" of down, for a total of 12" at the wheel...

Based on the polish visible on the shock shaft I'd say you're pretty close to spot on with that 3" estimate, and maybe just a tad generous. Given that, 9"-10" of droop would be quite a drop.

You just need to remember that a TTB suspension is basically two levers that pivot at one end with the wheel at the other end. Both the bumpstop and shock are at mid-points on the lever... If the lever (axle beam) is able to move up say, 3" where it hits the bumpstop, the wheel (at the end of the beam) can move up maybe 5". So it's definitely possible there's 5" of uptravel, and 7" of down, for a total of 12" at the wheel.

And I hope that it's just the angle of the pic and I'm not seeing a gusset up at the top, but that tubular radius arm with the upper tube that appears to be welded straight to the side of the axle beam right in the middle is a failure waiting to happen. The radius arm needs to span the entire width of the axle beam top-to-bottom (including the section of box tubing, if used) where it attaches to the beam.

The driver side radius arm alone bears the entire torque load being generated by the front differential, so it needs to be sturdy as possible (and gusset up top or not, the tubes should be gusseted or plated along sides for support also). For those here building their own arms, take a look at aftermarket arms such as Skyjacker or Camburg to get some ideas.

I'd also suggest try to design it so that it's similar to the OEM coil spring setup where the radius arm bolts to the axle beam rather than having the arm welded directly to it. To me it seems this way it would be even less likely to have a weld fail in this area over time.

Thanks Mwilliamshs

Yes, my intention was not to bash Agile's setup, however I learned a very long time ago that the mere fact something comes from a professional shop or business is not an absolute guarantee that it is of sound engineering or design, so that's only reason why I brought it up. My intention was that IF the concerns I mentioned were present, I did not want to see philos or someone else copy it into their own design not realizing it (and at the same time suggesting to Agile where an improvement might be possible).

I do hope it is just something I'm not seeing in the pic that was posted. A better pic of the area where the radius arm attaches to the axle should put this to rest if so.

We have built dozens of Prerunners and Race Trucks with the same basic design - as have many other builders. We have literally 10's of thousands of off road miles including Baja wins with the same basic design. We have proven it over and over. I would never build a bolt-on radius arm design like you mentioned above. I have seen way too many failures. I raced Stock Full F Series trucks for several years and those radius arms were the weak link - even with cheater 4130 "Stock Radius Arms" made specail for us by FORD - complete with stock part numbers on them. The bolt is a fulcrum point...

So you guys measure travel with the coil removed?

That is how you objectively measure the (up) travel of any coil spring suspension.

Why? Seriously.