IdaSHO

IDACAMPER

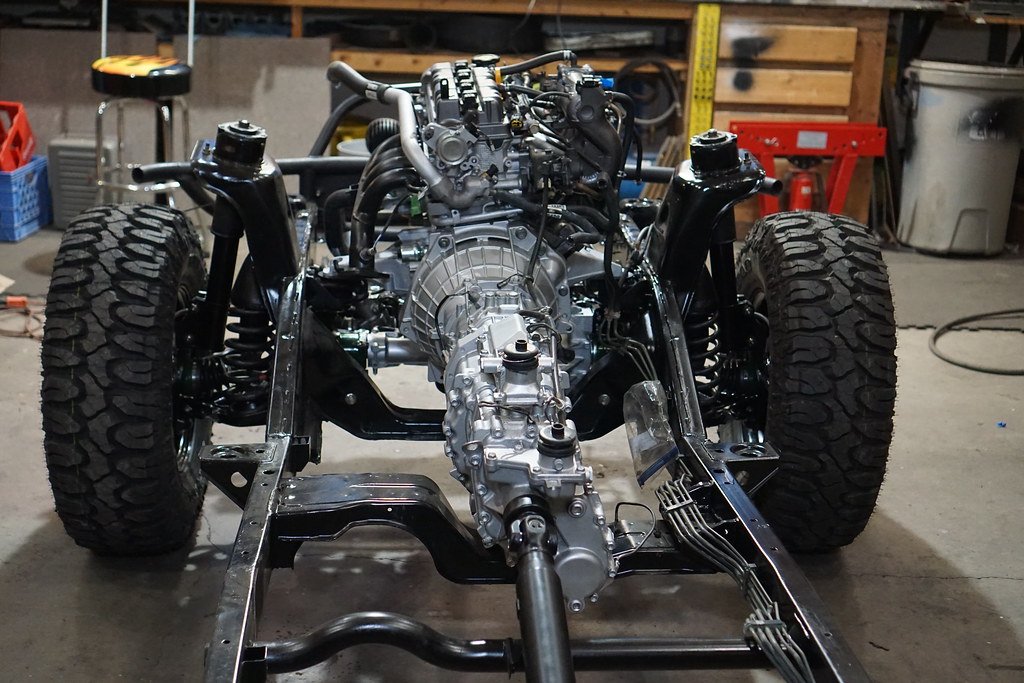

Then its time to get the motor and trans sorted and mated.

Fresh rear main seal, freshly surfaced flywheel, proper Japanese pilot bearing and Exedy clutch kit including throw-out bearing.

And after the typical nonsense getting things lined back up, engine and trans were mated and in the chassis.

Fresh rear main seal, freshly surfaced flywheel, proper Japanese pilot bearing and Exedy clutch kit including throw-out bearing.

And after the typical nonsense getting things lined back up, engine and trans were mated and in the chassis.