DIY Synthetic Winch Line

When I decided to put a winch on the Rover, I decided that I was going to try to learn as much as I could about the the different aspects of all the components I was installing. For example, making custom in cab controls, the different styles of solenoids, remote mounting solenoids, synthetic vs cable winch, etc.

This particular post is going to be about winch lines. I know there is a debate about which is "better", but let's be realistic, people have their own reasons for buying either one.

I had a cable winch line on my Warn M8000 that was mounted to the Wrangler I had many years ago. It worked, it saved me many times, performed adequately overall, and never once failed me. However, once I got it out past 50' in the mud, streams, and embankments, it was.a pain to maneuver or haul it around. It was a pain to feed back in properly without causing kinks or flat spots on the trail and the whole "I will re-spool it properly when I get home" thing, rarely seemed to happen. I know i sound as if I am whining, but I am just sharing some of my experiences.

It's heavy, pretty inflexible, dangerous if it breaks, can kink or flat spot fairly easily, and is annoying to have to re-spool it after each outingl. Although it is fairly simple to repair out in the middle of nowhere, I am still not entirely onvinced it is the way to go.

Synthetic winch line, well this is my first go around with the stuff and so far I am loving it. It is easy to work with, also easy to repair out in the middle of nowhere, and not as dangerous when it breaks. Light, very flexible, doesn't need to be despoiled every time, won't kink, and won't flat spot. It does have drawbacks too though. It is WAY easier the accidentally cut, it picks up grit/grime, is badly effected by UV light exposure, and has a lot more stretch to it.

All this being said, both have their drawbacks and advantages. Like I said before, the cable worked adequately, but this time I am going to try Synthetic.

So, here we go. I bought bulk Master Pull synthetic winch line. You might not believe this but, buying an already made up winch line direct from Master Pull is very close to the same price as the DIY winch line. When I included the bulk winch line., thimble, hook, end retainer, rock guards and splicing fids; there wasn't much difference price wise. However, with the DIY winch line, I would get the line I wanted, the rock guards in the length that I wanted, the hook I wanted, thimble I wanted, etc. Plus I would learn a valuable new skill set to put away for down the road, in case I needed to do repairs or something at a later date.

This is how it went:

Here is some of the items I bought. Tubular webbing (the 2 packs in the middle) is what all of the "rock guards" are made of, it is much cheaper to buy in bulk, and I won't have to have a name or logo on it. The rest of the items are fairly self explanatory.

Here is a mistake I made. The hook on the right is big enough to loan out to crane operators. I read the description wrong and thought it could be all that big (It was on clearance for something like $20 - $30). It turns out that yes it can actually be gigantic. The one is the proper size, strictly speaking, maybe it is one size larger than I really need but it is better to be safe, rather than sorry.

The thimble is extremely nice and well made. I am very impressed with how robust it is. Thankfully, I got the right on the first attempt at purchasing.

This winch hook has an area that allows me to simply slip the thimble into its proper position. Not all hooks are this well though out, some would have to have the thimble bent open to slip into position and then bent closed again.

The little bit of money I saved buy going the DIY route allows me to buy enough extra synthetic winch line to make a winch line extension/recovery rope. Winch line on the left, recovery rope on the right.

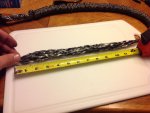

To start the loop/eye that goes through the thimble and feeds back into itself, I started by marking off 36" on the winch line.

I then placed a piece of very thick heat shrink tubing center on the area that was going to be exposed in the open portion of the thimble. This is to protect the winch line for sun/UV rays, but also to protect from abrasions.

The. I just fed it through and centered it to make sure none of the winch line was exposed.

Then I electrical taped the end of the line.

. Big trip scheduled next month, so I have a deadline. And all the correct pieces (I think).

. Big trip scheduled next month, so I have a deadline. And all the correct pieces (I think).