pappawheely

Autonomous4X4

Nice project. That truck will last forever.

If you are going to work on the rear are there any interest in doing a locker? I know it is 2wd so I thought you might think about it . With that said I have probably reread your build about 3 times now I really like these old trucks and this one is a keeper.

yea, i really need to put something there sooner or later...just been trying to find the time to draw something cool that won't be a knuckle slicer at the same time. good eye, most people accept that as a "job well done"...its pretty hack, don't look at it from the side profile or you'll see that it was done late on a hot afternoon and is more or less an afterthought!1) consider welding in gussets in the corners of the brace running above your engine between your shock towers, namely to reinforce the joint between the flat tube and the short pieces connecting it to the towers. One of said corners is seen here in this pic:

i always forget about the TrueTrac, but most of the suppliers I work with rarely stock them for a D70. Keep in mind, most of the Dodge D70's are 32 spline, not 35 like mine; there is precisely 10000000 variations of D70 BOM's out there, not nearly as simple as the ubiquitous potato rut digging 14 bolt. The mud truck guys I sell parts to all swear by the Spicer Power Lock, its the Dana Spicer version of a clutch posi and they are pretty legendary among the old school guys before all the fancier new diffs came out.2) is the the Detroit TrueTrac available for your axle? It's a torque-based differential that a lot of people seem to like for trucks that tow heavy and thus cannot tolerate a typical auto-locker, quite good street manners. Another thing to possibly consider is entirely swapping the rear axle out for something more modern and/or common, for example a GM corporate 14-bolt (bonus points for them being available with factory discs for like 15 years now). Would likely require moving the spring perches, but seeing your work so far I kinda doubt that would be a problem for you.

my truck lives by 2 mottos: "thank the lord for the big block ford" and "beam team always wins"Oh, and good on your for considered a TTB front 4WD suspension instead of a solid axle. TTB gets no respect for how durable and resilient the design really is, while still providing a much smoother ride than a solid front axle.

Eh, we call that a work in progress. Can't always do all you want at once so often having some part done is simply better than not having anything at all, plus by the time you finish the project you often come up with ideas that are better than what you had planned initially.yea, i really need to put something there sooner or later...just been trying to find the time to draw something cool that won't be a knuckle slicer at the same time. good eye, most people accept that as a "job well done"...its pretty hack, don't look at it from the side profile or you'll see that it was done late on a hot afternoon and is more or less an afterthought!

The Pwr-Lock is a great diff indeed, especially the 4-pinion kind (seem to recall seeing somewhere than the newer ones are 2-pinion only). The ability to restack their clutches to adjust their grip is pretty neat, sure wish the Sterling axles could be done the same way...i always forget about the TrueTrac, but most of the suppliers I work with rarely stock them for a D70. Keep in mind, most of the Dodge D70's are 32 spline, not 35 like mine; there is precisely 10000000 variations of D70 BOM's out there, not nearly as simple as the ubiquitous potato rut digging 14 bolt. The mud truck guys I sell parts to all swear by the Spicer Power Lock, its the Dana Spicer version of a clutch posi and they are pretty legendary among the old school guys before all the fancier new diffs came out.

May want to investigate '99-up Econoline vans, as some came with disc brakes from the factory, pretty sure limited-slip was also an option. Downside is they typically have something like 4.30 gears, well I suppose if you had big tires that would be a good thing but with what you're running now such gears will latch onto your wallet like a bloodsucker if you like driving faster than 45 mph. Oh, while I remember, check the load rating on your new wheels. The extra-wide factory steelies you removed from that D70 were quite strong, however that hasn't always been the case with aftermarket wheels, and you probally don't wanna be running 2200lbs wheels on a 6000lb-rated axle even if tires do allow it :ylsmoke:i know a disc'd 14 bolt is the sensible thing to do...i just like Dana axles better. hard to argue with a nodular housing thats not only smaller and lighter than a 14 bolt but stronger too, as well as 35 spline shafts. Don't get me wrong, the 14 bolt is cool and they are so cheap and simple. i built one for my crawler, but if I were to do it over again and not on a college kid with a summer job budget I'd have gone D70. a full float 35 spline 9" hybrid has also crossed my mind, but that sounds expensive. my buddy built one in college, its been an awesome axle and the strength to weight and diff clearance ratio is unbeatable.

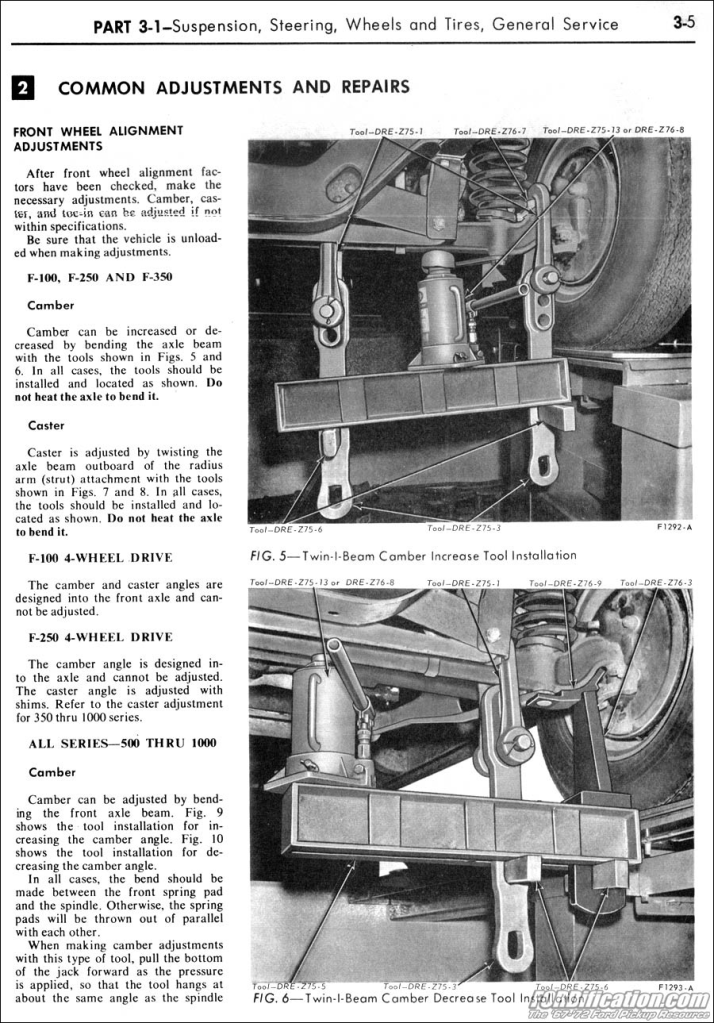

Speaking of which, you're lucky your truck is not a '78 or newer - those have shorter twin beams and while they do ride nice enough I still think the older longer beams terminating at each frame rail tend to ride nicer. Shame the radius arms were so short, but you already got that coveredmy truck lives by 2 mottos: "thank the lord for the big block ford" and "beam team always wins"having owned and driven a fair number of solid axle, beamed and A-Arm trucks...I'll stick with the sheer simplicity of beams. plus, you can align them with chain and bottle jacks!

plus, you can align them with chain and bottle jacks!

Yup, on a 2wd to 4x4 conversion we went with a factory TTB suspension due to its almost car-like manners on pavement while still being plenty capable after leaving the improved roads, a beat-up old tape measure and several $5 magnetic angle finders from Harbor Freight enabled us to do something the alignment shop struggled with for over two hours and ultimately gave up on. Of course our method did require removing the front wheels, which was something they screamed bloody murder against when we suggested it while truck was still on their alignment rack - cause God forbid they have to reset their fancy laser-beam machinery, lets instead burn up the afternoon doodling over how to break the taper fit between the adjuster sleeves and the upper ball joints with wheels still in place and little to no space to even swing a hammer, and in the process ruin whatever plans and/or schedules the customer might have had up until that point...You don't need to tell me that. I'm always amused at how younger "mechanics" hate the twin I-beam and TTB suspensions because they can't find a computer to tell them how to set it. I'm always like "give me a tape measure and some hand tools and I'll show you how its done."

I kept those wheels, since they are pretty rare. I have the matching set of original hubcaps too, just in case I get sentimental and decide to put some steelies back on someday. I need to find a new set of drive tires to put on those wheels, finding 33" mudders for 16.5" wheels isn't the easiest or cheapest thing to do nowadays though. Pretty sure the KMC wheels I got are rated to around 2500lbs, more than I'll ever put in the back of the truck most likely.Oh, while I remember, check the load rating on your new wheels. The extra-wide factory steelies you removed from that D70 were quite strong, however that hasn't always been the case with aftermarket wheels, and you probally don't wanna be running 2200lbs wheels on a 6000lb-rated axle even if tires do allow it :ylsmoke: