Let me first state that I have not (yet) built what you are attempting to build, nor am I an engineer. However, as a fledgling-novice-wanna-be fabricator and welder, I was suprised from the get go that you did not replace the cross member or at the vaery least, significantly gusset it and then box it in. I dont think there is much wrong with the arms or the bushings themselves. Its my opinion that the gusset from the tube to the arm is a solid idea/upgrade. As well, replacing the crossmember and plating it in to the frame by at least 8 inches each side (fore and aft) of its juncture with the frame would be adequate to remedy most of the problems you are experiencing.

Its obvious that you took alot of your design from AT, which is cool, they put in the time and know how to get a quality solution...gleen from it and make it on your own. The biggest discrepancy (and a major weak point) that I see in your design is the crossmember/mounts and how it/they relate to the frame.

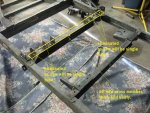

While I think 3/16" is plenty thick in most cases, I would also suggest that instead of the L shaped tabs that you are currently using to attach the arms to the crossmember, that you use a section of rectangular tubing with a cut away so that there is a built in "gusset" into these mounts. I would also add a lateral-gusset to the crossmember. The same hardware and bushings should work fine...you would access them with a deep well socket however.

Just my 0.02; please let me know if I am missing something obvious.