You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"TrailTop" modular trailer topper building components

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Thanks for posting this, as well as all the previous drawings and photos. All of us really appreciate you sharing your considerable time and expertise with us.

Thank you. And thanks to everyone who's been following this thread and posting their feedback, questions and criticisms - all of that really helps me end up with a better final design. I really appreciate the feedback, everyone please keep it up.

jscherb

Expedition Leader

Great work. Ive been lurking in this thread for a while. Honestly I think that if you made these pars your would sell a ton of them. It seems like a great way to get people who aren't quite all the way comfortable with building a TD to do it. It seems to make it so simple!

Thank you very much. I have no plans to sell these parts myself, I just design and build this stuff as a hobby. Maybe some company will decide to pick these up and market them, I don't know. Four of my other fiberglass designs have been licensed by three different companies, so who knows, maybe this one will get to the market too.

I am trying to come up with a design that does exactly what you said - I want to make it possible for people who aren't really comfortable with the idea of building a camper from scratch to say "hey, I can do that!". We'll see if I succeed at that goal

jscherb

Expedition Leader

A few days ago I posted some photos of a commercial camper called the Daytona, and a concept drawing showing how a similar shape could be built with TrailTop parts. Yesterday I received a request from someone who wanted to see a Daytona-style camper mocked up, so I did that for him...

This mockup is a little longer than my tub because I didn't want to cut the straight sections to length just for this photo; it's only a few inches shorter than the length of a Double Dinoot though, which would make a good platform for it. Also the read vertical piece is a bit long, again I didn't want to cut parts just for this photo.

And some shots of the original Daytona and my concept drawing for comparison:

Or built without a Jeep-tub trailer underneath, just would need a longer rear vertical piece and an 18" or so vertical piece under the front curve:

This mockup is a little longer than my tub because I didn't want to cut the straight sections to length just for this photo; it's only a few inches shorter than the length of a Double Dinoot though, which would make a good platform for it. Also the read vertical piece is a bit long, again I didn't want to cut parts just for this photo.

And some shots of the original Daytona and my concept drawing for comparison:

Or built without a Jeep-tub trailer underneath, just would need a longer rear vertical piece and an 18" or so vertical piece under the front curve:

jscherb

Expedition Leader

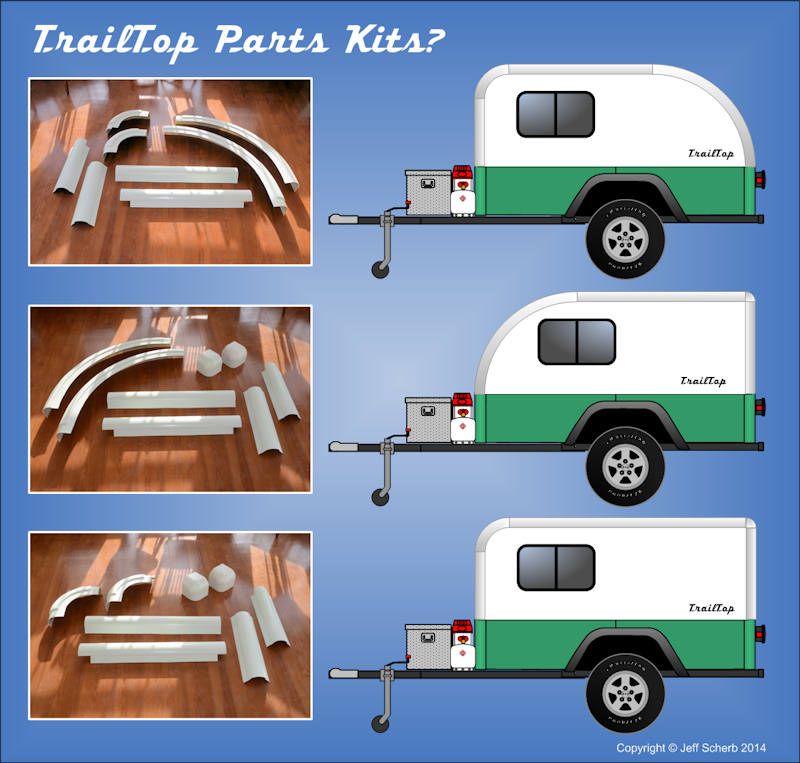

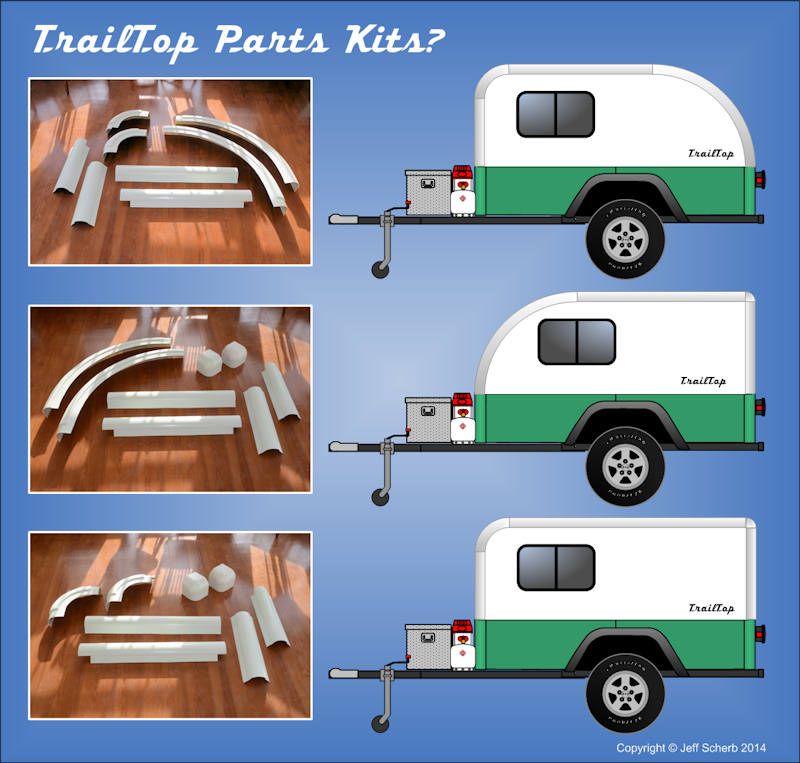

Now that I've got a bunch of TrailTop parts molded, this post is just thinking out loud... if the TrailTop system were to become a commercial product, "parts kits" for specific shapes/sizes of TrailTops could be offered. Here are three different style TrailTops for Jeep-tub trailers, along with the set of TrailTop framing parts necessary to build the top. (The straight pieces in these photos aren't necessarily the proper length for each particular design, I've just reused the same straight parts in each photo for illustration purposes).

Each kit could come with plans and instructions showing how to assemble and complete the specific model the kit was for.

Also, kits could be made with longer straight pieces for assembling trailers without Jeep-tub bases, like this one on a Harbor Freight frame I've posted before...

And for builders with their own designs in mind, the TrailTop parts could be sold individually so you could buy whatever you needed to implement your particular design.

Of course this is all just thinking out loud, because I do this as a hobby - I'm not in business to sell anything, nor do I plan to be. If these "kits" were to be sold, some company would have to sign up to market them, it wouldn't be me.

Each kit could come with plans and instructions showing how to assemble and complete the specific model the kit was for.

Also, kits could be made with longer straight pieces for assembling trailers without Jeep-tub bases, like this one on a Harbor Freight frame I've posted before...

And for builders with their own designs in mind, the TrailTop parts could be sold individually so you could buy whatever you needed to implement your particular design.

Of course this is all just thinking out loud, because I do this as a hobby - I'm not in business to sell anything, nor do I plan to be. If these "kits" were to be sold, some company would have to sign up to market them, it wouldn't be me.

Titanpat57

Expedition Leader

Excellent job!!

"A TrailTop in every pot!!"

"A TrailTop in every pot!!"

jscherb

Expedition Leader

I'm curious, what is the best way to cut the straight sections to get a nice cut? Chop saw? I've not worked with fiberglass before, so I'm not sure what it's like to work with. Thank you.

Fiberglass is best cut with an abrasive cutter, not a saw. Saw teeth cause impacts, which can chip off gelcoat at the cut line, crack the edge of the cut or cause "micro cracks" which can turn into bigger cracks later, so using an abrasive cutoff wheel or a diamond cutter is the best route. I use a 1/16" thick cutoff wheel in my 4 1/2" angle grinder for straight cuts, and for cutting a sharp radius, like the inside curve on the 12" radius corner parts, I use a 1 1/2" diamond abrasive wheel in my air die grinder. After cutting I usually smooth the cut with sandpaper.

jscherb

Expedition Leader

One of the other applications I designed the TrailTop parts for is a simple hard cover/tent platform to go on top of a Jeep-tub/Dinoot trailer. I've posted this concept drawing before:

So now that I've got some parts out of the molds, here are some TrailTop parts just setting on my yellow trailer; they're not trimmed at all for this application (the bottom flange has to be removed, for example), they're just setting there to give a rough idea of what a TrailTop hard cover would actually look like.

I've done a little editing on this next photo, on the side I've removed the bottom flange, I've put in a partial top panel, and I've added a latch on the side...

So now that I've got some parts out of the molds, here are some TrailTop parts just setting on my yellow trailer; they're not trimmed at all for this application (the bottom flange has to be removed, for example), they're just setting there to give a rough idea of what a TrailTop hard cover would actually look like.

I've done a little editing on this next photo, on the side I've removed the bottom flange, I've put in a partial top panel, and I've added a latch on the side...

jonnyquest

Adventurer

Here's a thought: A manufacturer could have a website with popular configurations. Customer selects one, inputs base frame dimentions, and out pops a kits with the needed parts. You have a terrific concept. It seems much stronger, lighter, and easier to build that a conventional TD. I really hope this comes to market.

jonnyquest

Adventurer

How large a structure could be made with these components? Could a 12' standup be made?

Similar threads

- Replies

- 3

- Views

- 519

- Replies

- 2

- Views

- 648

- Replies

- 9

- Views

- 378

- Replies

- 9

- Views

- 2K

- Replies

- 0

- Views

- 460