jscherb

Expedition Leader

Bummer about that cover. I would like to see how that deck stuff holds up to a year our two outside. Cool idea though.

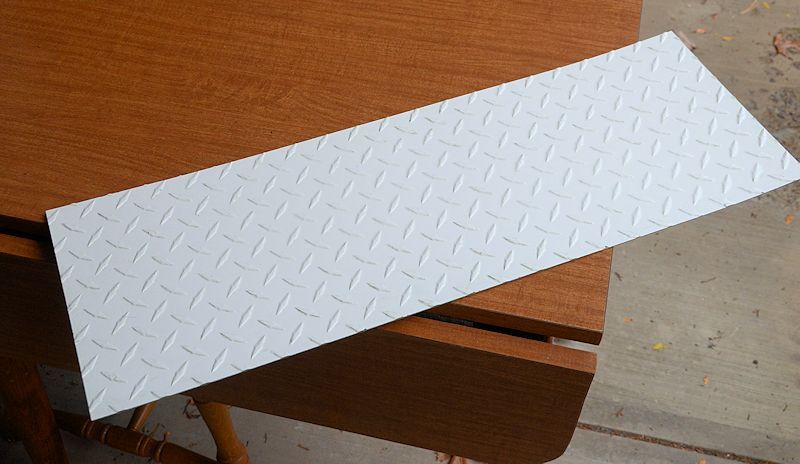

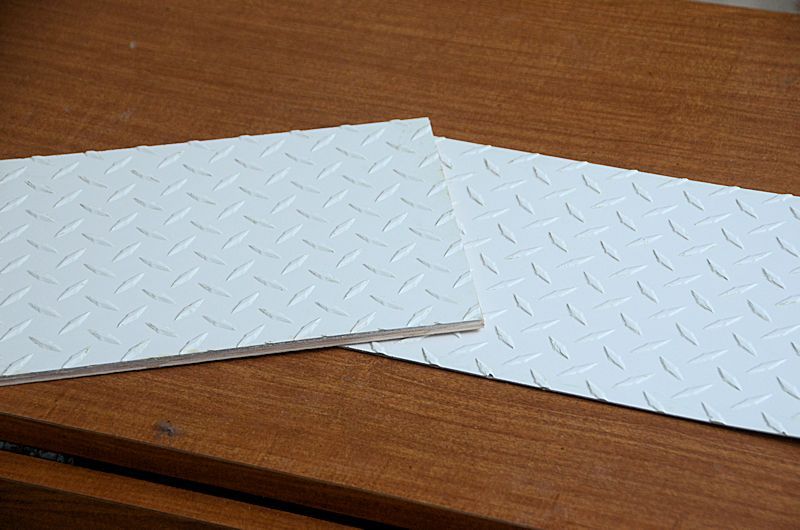

I'm putting one of the test samples below outside and plan to leave it out all winter.

Get your tickets to THE BIG THING 2026!

Bummer about that cover. I would like to see how that deck stuff holds up to a year our two outside. Cool idea though.

I love the idea of an all fiberglass exterior. How would sheet fiberglass compare to wood as far as weight? Could you easily bond rigid insulation to the fiberglass sheet?

I appreciate you sharing your ideas, really interesting thread.

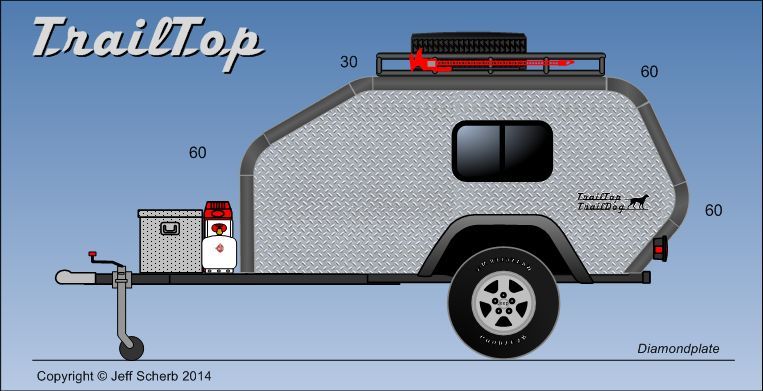

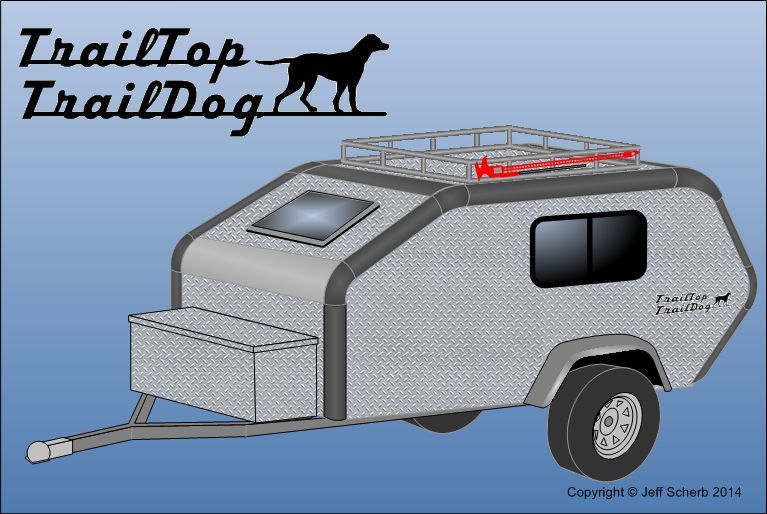

Is any of your teardrop style models close to be produced for sale?? I love all of them but really like your trailing!!!

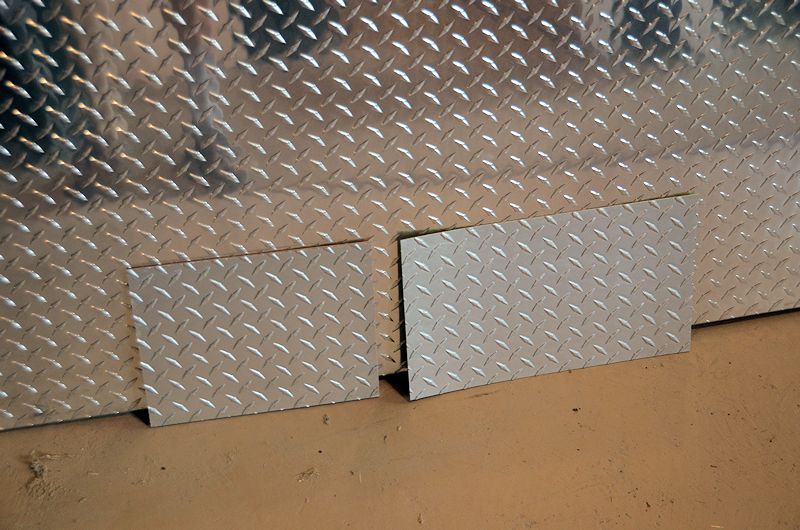

FWIW, I know fiberglass diamond plate is nothing new. My '01 Donzi (boat) used it in the engine compartment, though I swapped it out for polished aluminum for more bling. I have no idea if Donzi made the stuff in-house, but I'd assume not.

Not taking anything away from what you're doing - it's very impressive work. But the product may already be available.