whomisi

Active member

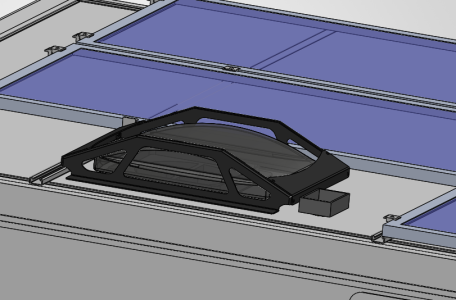

Small update for now, finally bit the bullet and cut some holes in the box. Started with the garage hatches since they're the most similar to the entrance door in profile, and least critical to get spot on. But they actually turned out great. Both in the same spot on each side. Took half the time to do the second one of course, and all the time measuring for the first one.

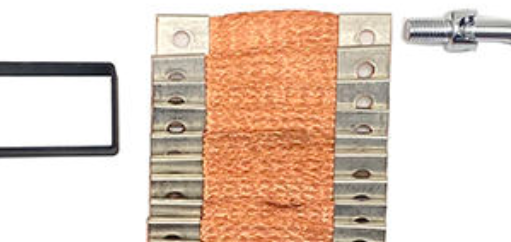

The Motorcraft hatches have a step in them, so you have to cut a different size hole inside and out. But the way these are profiled, the second flange is able to be glued onto the back side of the interior wall panel skin with the TC 50mm wall panels. Which means that not only the main front flange is bonded, but the inside is bonded too. I feel better about this, it makes the whole thing that little bit more robust.

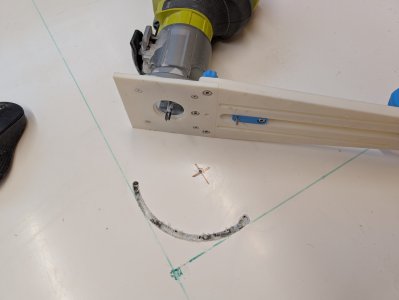

I cut large reliefs in the corners (32mm) and left the foam a little smaller than the main cut out. Then I just took it back slowly until the hatch fit just snug all the way around. That way I keep as much insulation as possible.

Plenty of glue and in she goes.

You can see from the inside I kept the cut out as snug as possible. I'm happy how it turned out, I will need a small trim around the inside and I'll cut back the hatch flange to suit with a oscillating cutter.

The only downside I now see to these hatches is the uninsulated latch. This will probably get moisture collecting on it in the winter. I'll have to keep the garage area nice and dry, which is a good idea anyway. We'll see.

The Motorcraft hatches have a step in them, so you have to cut a different size hole inside and out. But the way these are profiled, the second flange is able to be glued onto the back side of the interior wall panel skin with the TC 50mm wall panels. Which means that not only the main front flange is bonded, but the inside is bonded too. I feel better about this, it makes the whole thing that little bit more robust.

I cut large reliefs in the corners (32mm) and left the foam a little smaller than the main cut out. Then I just took it back slowly until the hatch fit just snug all the way around. That way I keep as much insulation as possible.

Plenty of glue and in she goes.

You can see from the inside I kept the cut out as snug as possible. I'm happy how it turned out, I will need a small trim around the inside and I'll cut back the hatch flange to suit with a oscillating cutter.

The only downside I now see to these hatches is the uninsulated latch. This will probably get moisture collecting on it in the winter. I'll have to keep the garage area nice and dry, which is a good idea anyway. We'll see.