Iain_U1250

Explorer

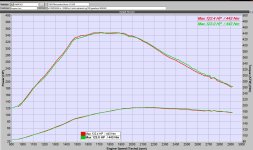

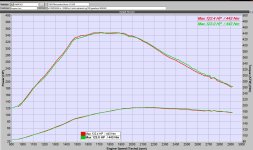

I put the truck on a dyno last weekend,

Our truck makes 123HP / 440Nm at the wheels, and has a nice flat torque curve between 1800-2200rpm.

The air/fuel ratio is where it gets interesting, as it shows that the truck is running quite lean for a diesel, especially when the boost climbs. It is quite visible in the video where the EGTs start to drop once we get over 1800rpm.

I put these two graphs into ChatGPT and asked for an interpretation as in description for the video.

Unimog U1250 Dyno Run – 123HP / 443Nm at the Wheels

This dyno run was carried out on our 1984 Mercedes-Benz Unimog U1250, fitted with a GT2860RS ball-bearing turbocharger (replacing the factory unit), a water-to-air intercooler, 4-inch exhaust, and UG100 gearbox on 365/80 tyres.

Results:

The torque curve is broad and flat, with over 400 Nm available from 1,500–2,200 rpm before tapering gradually. The GT2860RS spools quickly and maintains airflow consistently across the working range, giving a much stronger spread of torque than the stock turbo.

The AFR trace explains why power is capped where it is:

This video shows the dyno pull from start to finish, with power, torque, and AFR traces logged directly.

I think this is pretty true, still have a fair bit of range to play with fueling wise on the little turbo.

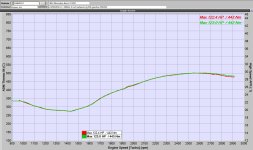

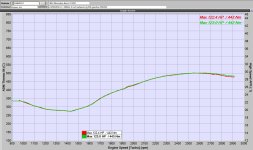

This is a dyno run from a stock U1700 ( 170hp OM352A)

CHat GPT compared the two results.

Our truck makes 123HP / 440Nm at the wheels, and has a nice flat torque curve between 1800-2200rpm.

The air/fuel ratio is where it gets interesting, as it shows that the truck is running quite lean for a diesel, especially when the boost climbs. It is quite visible in the video where the EGTs start to drop once we get over 1800rpm.

I put these two graphs into ChatGPT and asked for an interpretation as in description for the video.

Unimog U1250 Dyno Run – 123HP / 443Nm at the Wheels

This dyno run was carried out on our 1984 Mercedes-Benz Unimog U1250, fitted with a GT2860RS ball-bearing turbocharger (replacing the factory unit), a water-to-air intercooler, 4-inch exhaust, and UG100 gearbox on 365/80 tyres.

Results:

- Max Power: 123 HP at the wheels (~91 kW)

- Max Torque: 443 Nm at the wheels

- Peak Torque: ~1,800 rpm

- AFR: ~28–30:1 across the rev range

The torque curve is broad and flat, with over 400 Nm available from 1,500–2,200 rpm before tapering gradually. The GT2860RS spools quickly and maintains airflow consistently across the working range, giving a much stronger spread of torque than the stock turbo.

The AFR trace explains why power is capped where it is:

- At idle through ~1,100 rpm, AFR is lean (≈30:1).

- Between 1,100–1,400 rpm, AFR dips slightly as fuelling rises with boost onset.

- By ~1,800 rpm, torque peaks at 443 Nm, yet AFR is still lean at ~29:1 — showing fuelling, not airflow, is the limiting factor.

- From 1,900–2,400 rpm, AFR stabilises around 29–30:1 while torque holds strong, again pointing to untapped headroom in fuelling.

- Even as torque falls after 2,400 rpm, AFR stays lean, meaning the turbo still has capacity.

This video shows the dyno pull from start to finish, with power, torque, and AFR traces logged directly.

I think this is pretty true, still have a fair bit of range to play with fueling wise on the little turbo.

This is a dyno run from a stock U1700 ( 170hp OM352A)

CHat GPT compared the two results.

Power

- The U1700 makes ~119 HP, while your U1250 makes ~123 HP.

- On paper that’s similar peak power, but remember:

- The U1700 is running near factory boost/fuelling.

- Your U1250 is on a modern GT2860RS turbo, but fuelling is holding it back (AFR ~30:1 is too lean for best power).

Torque

- U1700: 363 Nm

- U1250: 443 Nm

- Your truck makes ~80 Nm more at the wheels — a big deal in low-speed off-road pulling.

AFR (Air-Fuel Ratio)

- U1700 runs in the 23–25:1 range at load → closer to ideal diesel performance tuning.

- U1250 runs very lean (28–30:1) → safe, but leaves significant headroom for fuelling adjustments.

- This explains why the U1250 makes more torque (thanks to modern turbo/intercooler airflow) but doesn’t make much more HP: fuel is the bottleneck.

Boost

- U1700 graph shows ~8–9 PSI, fairly typical of a stock OM352A turbo.

- Your U1250’s GT2860RS can comfortably support 15–20 PSI with good response. At current fuelling it’s under-utilised.

Torque

- U1700: Peaks at ~363 Nm

- U1250: Peaks at ~443 Nm → +80 Nm gain

- Your U1250’s torque comes on earlier and stronger, then holds steady across the working range — much more usable for off-road and towing.

Horsepower

- U1700: 118.7 HP

- U1250: 123 HP → only +4 HP difference at peak

- Why so close? Because your AFR is very lean (~30:1), limiting fuel delivery. The GT2860RS turbo clearly has airflow overhead, but fuelling is capping top-end HP.

Power Delivery

- The U1700 has a smoother “stock” curve, but runs out of breath above ~2,400 rpm.

- The U1250 feels stronger in the mid-range thanks to modern turbo efficiency, but top-end HP hasn’t increased much due to conservative fuelling.

Last edited: