-Since completing the interior build we have been trying to find a solution to one of one problem that we were not really expecting, which was the flooring. We love the coin flooring and have been super happy with it and would do it exactly the same way if we were to do it again, but our dog Ace is not as much of a fan of it. Something that we have noticed especially now that he's getting a little older he tends to slide around a lot on it while we are driving if he walks around. For the most part, he's good about just lying down, but there are times that he is feeling antsy and then he just can't seem to get a good grip on it. Our temporary solution was adding in a small rug which helped a lot, but that meant he really could only again stay in one spot while driving. In addition to him sliding around at times, we have also worried about if we did damage teh floor in any way it wouldn't really be an option to redo it as it runs under all the cabinets. The flooring is extremely durable but we figured there must be a good solution out there.

After some internet searches, I came across

inhabit Design Works out of portland Oregon which makes custom rugs/floor mats for sprinters using a woven vinyl material. From all the reviews everyone who has them seems to love them say they help provide a softer floor, they're easy to clean, and suppose to give more grip for a dogs. So after reaching out to them to get a quote to do a custom floor mat/rug set up I decided it was worth some effort to figure out how to do it myself. Don't get me wrong I think they make a great product, but it was too steep of a price to make it worth it for us.

So I started on my search for a product that would get the job done. After some time I found

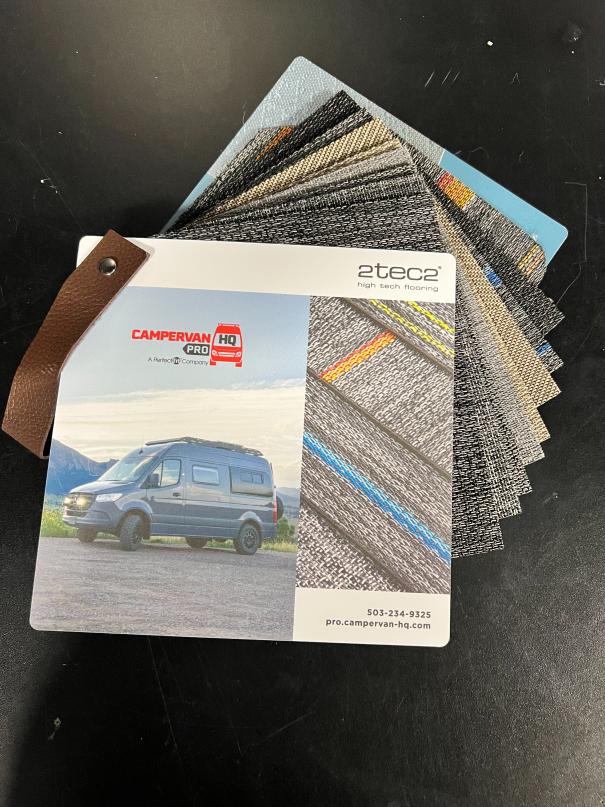

2tec2 flooring on Perfectfit's website. This product is very similar to the Chilewich material used by inhabit but was more affordable (still very pricey though). I order a sample pack just to make sure it was what we wanted and so we could see the colors in person.

The material felt very durable, easy to clean, more easily replaceable/ repairable if damaged, and seems like it will give more grip for our dog. Also due to it having a felt backer, I think it will help keep the floor a little warmer for those cold winter nights. Once we got the samples we did some tests just to make sure it would be a good fit for us. It passed our scratch test with flying colors though the grip test wasn’t 100% conclusive but it does seem like would be an improvement over the coin flooring. I was the least confident in how the material would handle a water test. For that, we first ran water over it in the sink and surprisingly it beaded right off so we took it up a notch and submerged it for a while in the sink. Unsurprisingly the felt did soak up some water but after an afternoon on a window sill in the sun, it was 100% dry! That sealed the deal for me and sent me on the next search, how to finish the edges without a sewing machine, and how to secure it in place. After thinking through multiple ideas for finishing off the edges I finally came across an idea that I liked and seemed like it would work! The plan was to use a rubber edge seal trim. This would be easy to install, easy to replace, inexpensive, and give it a clean finished look without the added cost or struggle of trying to sew through the thick material. So I ordered a bunch of different options from Amazon and started testing them out on the sample pieces. After doing a couple of tests I found our favorite one and placed an order for the material and edging. Then it was time to test how well a snap would work in the material. I ordered a cheap tool from amazon to help do that install and it worked perfectly so it was go time! I ordered all my materials and started on my template.

Test Piece Number One

The Start of The Template

Since I have toe kick lighting I decided to only use the edge trim on the outside edges to help minimize the impact on those lights. The material is still run all teh way back under the toe kicks though to help lock it into place and give it a seamless look.

Traced the template out on the backside of the material.

First Test piece in the van.

Ace approves of the floor mat

Decided to cut the outside edge after getting the inside edge all locked in.

Still pretty thin even with the rubber edge seal installed.

Was able to run it all the way up to under the front Husky floor liners.

Still might add a few snaps on the outside edge but so far it's not moving

After getting the main floor section done I had quite a bit of material left over so I went ahead and used it for the factory step locations.

Passenger side step

Driver side step

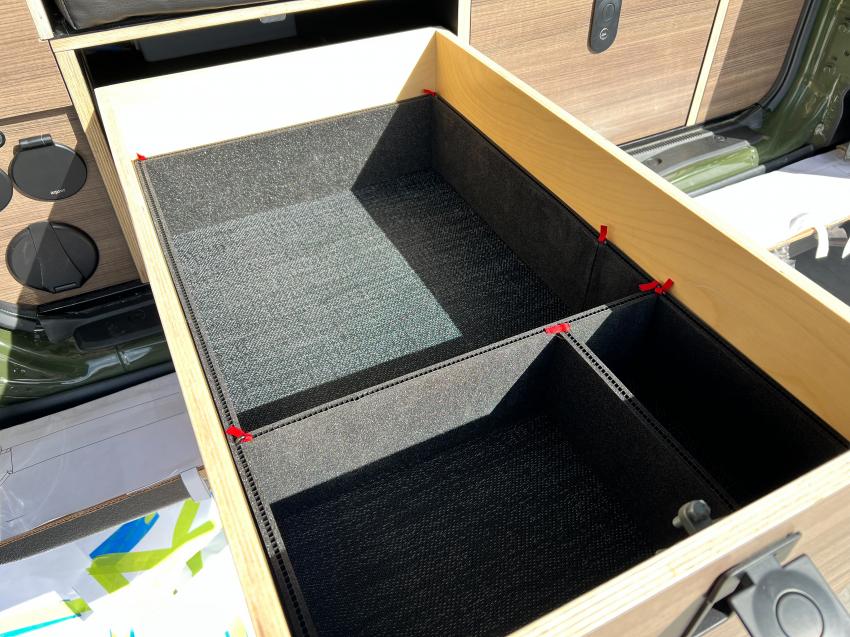

I still have a decent amount of material left over so I am going to make inserts for all the drawers in the van. I will post some more pictures once I get those done and any other added areas I may do depending on how much material I have left after those.