From the tech paper on syn rope in hot environments:

Syn is a size-for-size replacement for wire rope, but weighs 1/7 of equivalent wire rope.

Syn reaches temperature equilibrium in 30 minutes or less. Meaning that if the air temp around your winch rises from 100F to 200F, your syn rope is at 200F internal temp within 30 minutes. Time-to-temp depends on rope diameter and single strand vs multi-strand. Smaller diameters reach equilibrium faster than larger diameters.

At 120F ambient, the rope will stabilize after about 20 hours and will lose 8% of its tensile strength. Last September 3 in Yuma, the lunch time ambient was 118F, in the shade. Hotter in the sun, hotter around the winch with the engine running, hotter still if you are doing a pull. The loss of tensile strength accelerates rapidly as ambient temps increase. AT 170F for 20 hours, the rope has lost about 25% of its strength, but after 40 hours at that temp, it has lost about 40% of its strength, and the loss of strength continues at that temp until it reaches about a 45% reduction at about 75 hours. At 212F, syn has lost about 75% of its tensile strength after 30 hours.

With conducted heat (as in heat conducted from the winch drum) the internal temp if the syn rope will stabilize after about 100 minutes, but will never reach the temp of the surface that it is in contact with. As an example, a 1-5/8" rope on a 70C hotplate stabilizes at about 40C after 100 minutes. Rope diameter is a factor, so expect that 7/16" syn will reach internal temp much faster, and heat is the rope's enemy. Sheathing or covering does make some difference, so a protective cover on the first wind of the syn rope seems to be a good idea.

As I understand the concept of Creep Lifetime (continual time at temp and load), the syn ropes will exhibit some initial fiber elongation (stretch), then move to some permanent fiber elongation, then move to rapid elongation and fiber rupture, but the progression of this sequence depends on a combination of both temp and load. My layman's conclusion is that our ropes are under load for such relatively brief periods of time during a pull, that creep elongation is not much of a factor. Could also be that I just don't fully understand creep lifetime, which is the time/temp/load combination that leads to fiber rupture and rope breakage.

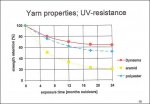

Here is the link to this paper. I'm still looking for material on UV resistance, but the authors of this paper claim good resistance to UV, but without any supporting data.

http://www.samsonrope.com/site_files...t_Climates.pdf