yabanja

Explorer

As far as Robinson Fuso's frame cracking.

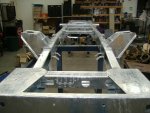

I'm sure you are talking to guys much smarter then me, but with all the cracking (before and now) and how much you have invested in the truck (both time & money) I'd do what Doug looked into and replace the rear frame (aft of the step) with custom frame rails. The cost seemed reasonable and it will only take another failure in a bad location (geographically) it make the swap worth while.

Welding patches on the frame is not the way to fix a frame. That 'fixes' the problem in the short term, but creates a stress point for problems down the road.

I'd say your 'wreaker guy' is in a different boat then you. Every day that wreaker returns home to the shop and if there is a problem a reasonable fix in the shop.

Robinson Fuso might be on the dark side of the moon when the failure happens, so not so easy of a fix.

Either that or replace the 3 point system with a full length supported subframe for the camper and/or lose a ton or more of weight.

I agree. Changing to a heavier gauge rear frame section would be the way to go IMHO.

The factory service manual says welding on these frames is a big no-no due to the high tensile steel.

I am not sure I would condemn the three point mounting system for every application based upon the failures experienced here. This vehicle seems to be exceeding the weight limits that the Mitsubishi engineers intended by a significant margin. (I have yet to hear any answers to the question-how much) The vehicle has also traveled extensively in extreme conditions. It is likely just plain tired!