rockyroamer

Member

Hi there, long time user on the forum under a different username (dsmith01). I just picked up a 2003 E450 Wheeled Coach at auction a while back and figured its time to post some progress. The municipal auction was in KC and I'm located in Denver so had to figure out how to get the ambulance home. After one failed trip, that was nothing short of a disaster, with a trailer that was too short I finally got it unloaded into the driveway.

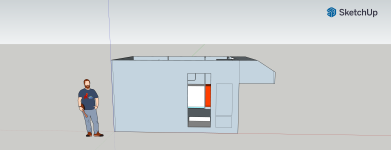

I have some big plans for this ambulance. Ujoint 4x4, raised roof and cabover sleeping loft to name a few. Here's the progress so far.

Next, I ripped out the interior and electrical.

For the electrical, I traced every circuit back to the board. In the end I eliminated every circuit on the board and removed all of the legacy components in the box. While time consuming, it was a good learning experience and in the end I was able to fully understand how wheeled coach tied into the van.

Here's the fully gutted ambulance.

I have some big plans for this ambulance. Ujoint 4x4, raised roof and cabover sleeping loft to name a few. Here's the progress so far.

Next, I ripped out the interior and electrical.

For the electrical, I traced every circuit back to the board. In the end I eliminated every circuit on the board and removed all of the legacy components in the box. While time consuming, it was a good learning experience and in the end I was able to fully understand how wheeled coach tied into the van.

Here's the fully gutted ambulance.