Thanks for the compliment, and glad my trailer has given you a few ideas.

Few things, what will you be pulling the trailer with?

No worries, Your trailer is worthy of praise!

I will be pulling it with a 97 Jeep Wrangler.

Also, I struggled to find premade trailer fenders that were wide enough to cover the tires I used. The last thing you want is to have the trailer tires throw rocks at the back window of your tow vehicle, or at you and your passengers if you're in an open top vehicle like a Wrangler. Along those lines, it's a small hassle but it will take a little extra fab work to make a good mounting surface for the fenders with the tub uprights on the outside. No big deal though.

Thanks for the tip. I'll keep that in mind. The kit I bought has prefabbed fenders. I wont be putting any big tires on it. I hope to find some used JEEP rims at the salvage yard and put basic tires on it.

So a few impressions of my trailer now that I've used it a few times.....

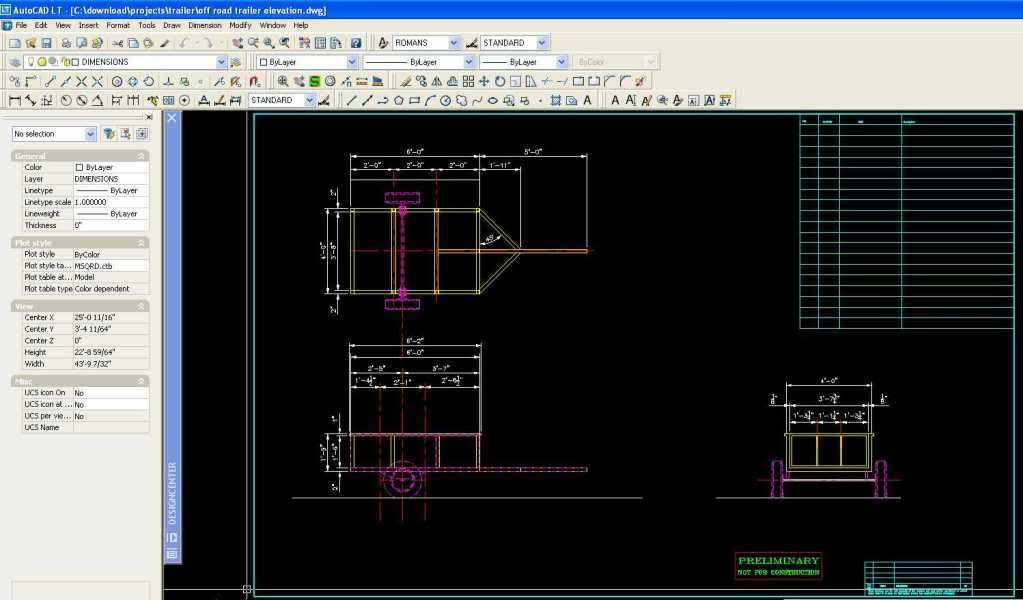

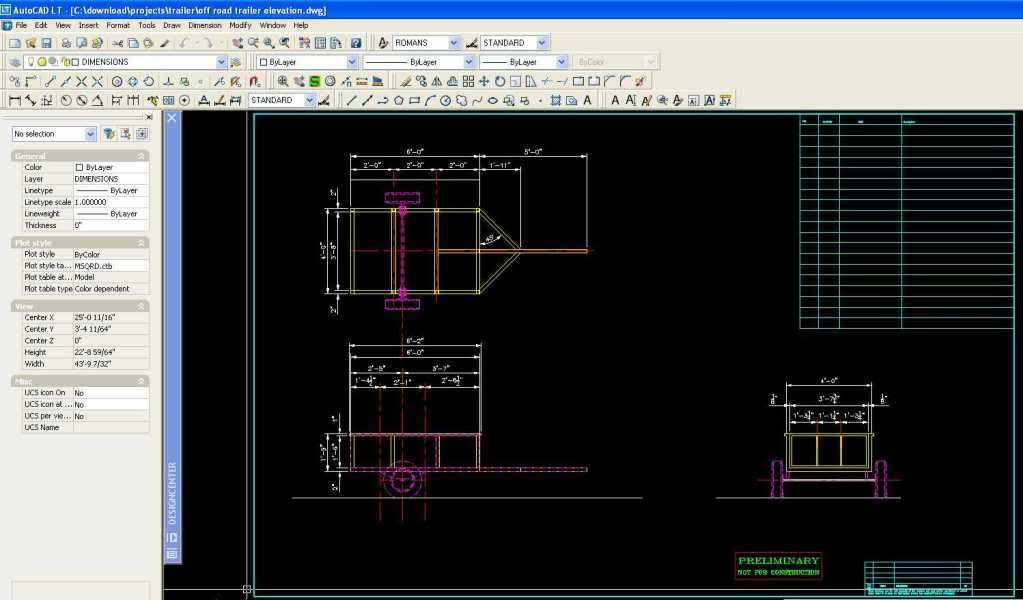

1) Make the inside dimensions of the tub a minimum of 4x6' (assuming you are keeping the basic dimensions about like mine). My trailer frame (and tub) measures 4x6' to the exterior edges and since I used 1.5" tube for the uprights I am about 3" narrower than 4' inside the tub. Not a huge deal for how I plan to use the trailer but if I wanted to haul a 4x8' sheet of plywood it won't fit flat inside the tub on my trailer. Also, most ATV's are 4' wide at the outside edge of the tires so I could have also fit an ATV in the trailer had I planned that better. But since I don't own an ATV nor plan to, again it's not a big deal, just an observation that might help someone else.

Thanks, Its a good observation. I'll re evaluated my plans before cutting any steel.

BTW: I have a harbor freight 4'x8' trailer to haul building material on. My father also just bought a nice trailer I can use.

I am strictly using this trailer for vacationing, hauling firewood, camping, hauling deer out of the woods and hauling dirt/sand/gardening items in. I might make a few mods to put some risers to haul even more... still in the thinking stages of that.

2)5' tongue should be plenty long. For me the goal was to keep the tongue as short as possible without having it contact the side of the truck in a jacknife situation. This would allow me better maneuverability on tight trails. On my trailer, a 4' tongue ended up just about perfect for that. However with the addition of a water cans and a tongue box/cooler I've found that I need to be careful in situations like crossing a ditch where the trailer is pitched forward toward the back of the truck just so my spare tire doesn't make contact with the stuff on the front of the trailer. This hasn't been an issue yet at all and there seems to be plenty of room still but maybe a few more inches of tongue length would have been good. Personally I certainly wouldn't go any longer than 5' with the tongue.

A good measurement to go by is to take the wheelbase of the tow vehicle and make the measurement from the rear axle of the tow vehicle to the trailer axle close to or the same as the wheelbase measurement. That way the trailer will track very close to the same line as the tow vehicle. This is helpful on rutted tracks or tight trails etc.

I see alot of cool 'racks' for storage on the front of trailers. I'll probably add one later on as I use the trailer and get a better feel for my needs.

I don't really do any major 4 wheeling or rock crawling [yet] so I'm not so concerned with that aspect at the moment. I'll be on some low key logging trails & firebreaks usually.

3)My tub is ~19" tall which ended up working perfectly but only by complete dumb luck. I decided on the measurement purely by "feel" and what "looked right". I suggest taking a close look at the coolers, bins, fuel cans etc that you plan to put inside the trailer and make sure that they fit under the lip of the trailer. Like I said, my Scepter cans, coolers and just about everything I have fit extremely well but like I said, I didn't plan around that gear, it was complete luck. I'd hate for you to find yourself a little too short or something like that for the gear you need to carry just because someone didn't point out their own mistake and possibly help you from making the same one.

Thanks I'll keep that in mind. I thought about 'covers' and I'm not certain what way I'll eventually go. I love the look of your trailer so I'll probably use the 19+/- measurement.

4) I would not use DIY bedliner again. I used Raptor liner on mine which IMO is hands-down the best DIY bedliner I've seen. It's been "ok" at best, but because you will be constantly dragging things in and out of the trailer whatever bedliner you choose to use will get abused for sure. If you can budget it, I highly suggest a professionally sprayed bedliner like Line-X or the like. My Raptor liner is fine so far but I have concerns about its long-term durability. I'll be adding a rubber mat to the floor of the trailer to help reduce some of the wear on the liner and also reduce the sliding of gear.

I'm thinking of going with some thick wood decking for the flooring and some kind of roll on bedliner for the sides. I'm thinking of using 14 ga. for the sides.

Good luck and I'm anxious to see the improvements you'll make to my simple design.[/QUOTE]

I like the simple clean lines of your trailer. I doubt anyone could 'improve' your design. I'm merely going to copy, yet tweek to my personal needs. Since I'll be using it for multiple tasks I think keeping it simple will the best for my needs.

one thing I'm thinking is to use the 2x2x1/8 tubing for the entire project.

I also have to admit this is my first major steel fabrication / welding project. I normally work with wood.

Wish me luck as I hope to get started on it this weekend.