The past few weeks have been focused on long-overdue upgrades, maintenance, etc. At the same time I decided to upgrade a few of my tools and below is another example. Of course, I have owned wire strippers since the early 80s but I never really had what I considered a nice pair, so I purchased these

Klein Heavy Duty Wire Strippers which strip from 8-20 AWG stranded wire.

The paperwork is part of the

RAM Upfitter Electrical Kit (#68398184AB) that came with my vehicle.

I figured if I was going to spend more money on strippers I would do my best to spend locally. The local ACE have a great selection of nuts, bolts, washers, etc., so I also took time to look for large washers that would be used to square up my Maxtrax mounts. They had large washers but they were $2-3 each and for the price it was just easier to purchase a piece of flat stock to cut and drill. One note, they offered to cut for free so I accepted but ended up with an assortment of parallelograms. It works but is pretty ugly by my measure.

Here is a

Battle Born 100Ah 12V LiFePO4 deep cycle battery previously used on my Jeep as a house battery. What I am attempting to do is to wake-up the Battery Management System (BMS) since the battery has been in storage for the past nearly two years. Despite me charging the battery to 100% prior to storage and the company stating that "the batteries lose approximately 2-3% capacity per month" and they have a 10-year warranty, it appears that the $925 I spent on this battery will be a total loss.

When I contacted Battle Born they partially agreed with their instructions by stating that

"you should jump your battery within twenty-four hours of entering low-voltage disconnect otherwise you risk damaging your battery and voiding your warranty." The disagreement came when what they verbally stated their batteries lose around 5% capacity per month which is twice as much as compared to their instructions which state a loss of 2-3% per month. This is frustrating since they promote how rugged and reliable these batteries are while at the same time not really identifying what could potentially render a battery useless. I will continue performing testing and discussing this with Battle Born and will share the outcome.

Here is my

Maxxfan Plus (#00-04500K) which also requires service since the fan itself stopped working months ago. I took the fan apart and cleaned it up and after re-installing it and applying power the only part that seemed to work was the motor for automatically closing the cover. I will call Maxxair and post my update here.

Finally, a successful repair! Here is my

Helio Pressure Shower from Nemo Equipment that I have owned for approximately five years. Over the past few months it has leaked a few times with the occasional leak appearing to come from a partially failed valve inside the foot-pump. I called Nemo and discussed the problem with them and a few days later a new foot-pump arrived. A few minutes later the new pump was on and they pressure shower seems to be repaired. The new design seems to be much more robust.

Yet another successful repair this time on my Renogy

200 watt 12 volt monocrystalline foldable solar suitcase. What failed were the adjustment knobs on the legs - they rusted so bad that one seized up and the leg was rendered inoperable. The solar panels and charge controller still worked fine so I contacted Renogy and they shipped out another set or legs complete with mounting blocks, bolts, etc. To be fair, I did not receive two new complete legs - they appeared to be used and were missing a few small parts. This was not an issue for me since my goal was to bring the system back into operation and I was able to cannibalize the missing knob and bolts from the old components.

Here are the locks I finally selected to protect my four

Maxtrax MKII recovery boards mounted on the side of my pop-up camper. It will be interesting to see if these are able to stand up to full time use on the exterior of my adventure vehicle. Over the past few weeks I have been stopping at all sorts of placed and visiting many web site searching for the largest outdoor lock for the least amount of money that would work in conjunction with the

Maxtrax MKII mounting pins. Maxtrax recommends a TSA-style lock but they just appear to be small and weak like most guys these days.

These

Brinks 30mm solid brass 4-dial resettable padlocks are made in China out of solid brass using a steel shackle which has a cut strength up to 1200 lbs. Ultimately, if someone really has a desire to defeat a system like this - it is rather easy. Then again, when I travel I am usually inside or in close proximity to my vehicle most of the time while exploring the wilderness. It's only when I am in-town stopping into a store to stock up on supplies that my vehicle is most vulnerable. I do hope these last for a reasonable amount of time.

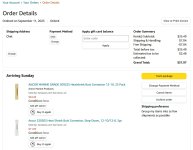

Not a favorite place to purchase anything but I occasionally enjoy a night spent in their parking lot so I don't feel bad spending money there sometimes. Receipt for reference.

Over the past half-century I have developed a small group of good friends - sort of an inner circle. One man was a fellow student at

Penn State University who also roadraced superbikes with me at

WERA events, another worked with me at

Lord Corporation in the High Energy Laboratory. A few worked at

Siemens VDO with me while I partnered with another at

NASA Langley Research Center. Recently, I lost one of my inner circle - we spent nearly two years together struggling through initial training in the military. When we finally graduated and looked back upon hundreds of quitters, and selected orders to our initial duty stations, we smiled knowing that we would always have each others back.

I am talking to the men out there, not the guys. If you are a man, you must expose yourself to tough times and dangerous situations to begin to form an inner circle. This does not happen quickly, it has taken me the better part of a half-century and I can count my brothers on one hand. This is how it is, always has been, and always will be. You don't develop meaningful and lasting friendship with other men during good times - it happens when things are tough and your respect, your reputation, or even your life, are on the line. My men have weathered many storms with me and they can count on me for anything with no questions asked. Anything.

A few of my brothers invited me to join them recently at a remote location. It was on the property of another fellow who seems like a nice guy himself. We talked openly and shared everything, as always. On public forums such as this I am required to temper my speech so as not to offend but in private, I have no filter - I let the truth out and I speak it with my chin held high, my chest out, and a smile on my face. At this point in my life I really don't care what others think or say about my beliefs, what I do, where I go, why I am who I am, etc. The four of us sat around a fire and devoured two pounds of bacon, two pounds of shrimp, and a dozen eggs.

I am where I am and I am doing what I am doing because I love freedom and despise tyrannical orders issued by despotic leaders. You guessed it, I didn't play well with others in grade-school. Now for some truth - stop worrying about your job, stop worrying about money, stop worrying if your wife or girlfriend will leave you, and stop making excuses - it's time for you to lift a heavy load and embrace the struggle, and love it. If you are one of the 3% of men who have the balls to do this - you will eventually form an inner circle. On the other hand, it you are like 97% of the guys, you will continue to serve and obey, just like a mindless slave.

So go get a truck, grab a gun, knife, and blanket, and head out into the wilderness to figure things out. The longer you are outside the more

open to the truth your mind becomes. Happy trails.