Fairing/Skirt Mold for the Camper - Drivers Side Front - Continued......

And now it is time for my Screw Up

! This wasn't even a Rookie move. This was like someone with zero trade experience, or someone who had never cut a piece of large contoured base board/molding. I have no idea what I was thinking, or obviously not thinking

. Let's chalk it up to burn out, working too late and/or being in the weeds.

I don't have a large (12" blade) table saw, radial arm saw, compound miter saw, etc......, so I had it stuck in my head that I was going to have to cut the needed 90 degree cross cut/on a 32 degree angle (on the CF main mold section) with one of the more basic powered hand tools I did have (skill saw, jig saw, sawzall). It was never going to work, but tunnel vision some how did it anyway. What a Wanker

!

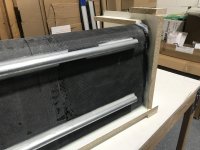

Lucky for me, my roommate just bought this. And the irony, it was sitting in the garage the whole time. Thanks Dan-Oh; you keep buying the cool tools and I'll keep borrowing them!

I had a small scrap piece, from the first cutoff on the main mold, that I was able to match up to patch my screw up. Not a huge deal, just one of those head shaking moments that keep you human and humble.

I then had to template all of the needed corner radiuses for the mold and modify/make a few fairing tools.

Fairing all the corners to match the needed/existing radiuses on the camper

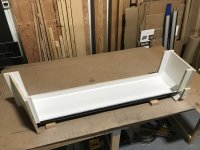

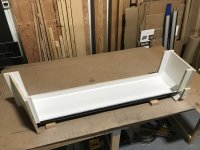

And finally a sealer coat before the release wax is applied

I'm going to let the mold dry/set up for another day, while I start cutting materials, and then hopefully get it laid up early this week

!