Prep & Dry Fit of Materials for Carbon Fiber Fairing/Skirt - Drivers Side Front

I'm always surprised at how long it takes to prep materials and do a layup

.

I still had some Kevlar left over from the inside of the wheel wells, so I decided to reinforce the front corners of the front fairings for both sides of the camper. This is probably one of the areas most prone to getting hit by rocks, road debris, etc. Two layers of Kevlar were used.

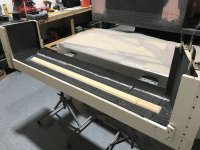

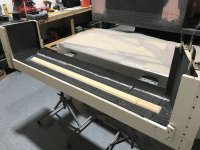

Dry fitting one of the CF layers

The mold has plenty of bends/contours to help reinforce the carbon fiber/part, but I also wanted to add something down the length of it, to help reinforce it and prevent any possible bowing. Any number of products could have been used, but I decided to use something I already had on hand, 1/2" thick Divinycell core. I beveled and rounded off the edges so the CF cloth could more easily form to it/to prevent air gaps.

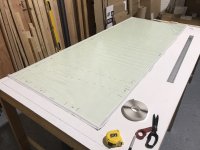

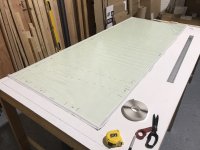

Now onto the consumables: peel ply, bleeder breather cloth (Not shown) and the vacuum bag. Note: Some use very large vacuum bags and they can just put a ton of slack in the bag, tacky tape it down/together and call it good. Unfortunately for me, I am only using the standard 110" wide rolls/bag, so I have to measure what I need to make sure I don't come up short-especially on complex molds/parts. I also pre-mark and pre-pleat everything because I am always pressed for time at the end of the layup, to get the part on a pump before the resin flashes off and starts to cure. I'm also working solo on these layups, so it's always a bit of organized-anxious-chaos by the end. Basically a good old fashioned Sh(smiley face)t Show!

I share this because, measuring, marking and pre pleating a bag for a complex part/layup takes fooooooreeeeeevvvvvver! The price you have to pay for being a one man DIY shop on somewhat of a budget

.

Technical Info for those interested:

I wanted to make sure that the layup schedule/weight of carbon fiber for the fairings/skirts was between 40-50oz. Some might say this is a little overkill, but this is an expedition vehicle, not a show car, RIGHT? I wanted them to be able to take a little beating if needed.

I could have just used two layers to get to the desired weight I wanted (I would have had to purchase additional/separate material), but I wanted/needed to use the CF cloth I had left over from the rest of the build. I also wanted to ensure the weaves of each layer were different/in a different orientation for added strength, so this mainly determined the number of layers I used. Additional thinners layers, for the first two layers used, also helped the CF cloth shape/contour to the mold better than a thicker single first layer.

Layup Schedule (Four Layers - 47.4oz Total):

5.7oz 2x2 twill (first-outside/top layer), 8.85oz 45 biaxial (second/middle front layer), 24oz plain weave (third/middle back layer), ½” thick 2-1/2” wide core foam (down center of front fairings) and 8.85oz 45 biaxial (fourth-most inside/back layer).

Kevlar used to reinforce the front corner was a 6oz-ish and a 10oz-ish.

!

!