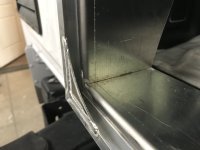

Camper Shell - Fairing/Body Work - Interior - Continued

Sanding the first coat of fairing material is always the worst

.

The first applied coat: in the bed area, on the pass through wall and the main walls of the drivers side wall are sanded. Now I'm laying down some camo and guide lines to apply a second spot fill coat. Certain areas on these noted areas/walls still need a first coat, but that wont happen until the second coat is applied and sanded on the original areas.

View attachment 805136View attachment 805137

View attachment 805135

View attachment 805138

I'm sanding the first coat with 80 grit and then any second or third spot fill coat with 180. Not much material is needed for the second coat, and I usually apply it evenly/smoothly, so there shouldn't be any high spots that would require 80 grit. Also, the final sand on my end, in prep for primer, needs to be 180, so I'm trying to save some time on sanding by just transitioning to 180 for the second/third coats.

The pass through took longer than expected at the fab shop, go figure, so I'm going to try and power through some long days/weeks of fairing/body work to make up some time. I'm also a little brain fried from all of the thinking and designing required on the pass through, so some mindless sanding will be a little break.

I'm also going to start on the molds for the fairings this weekend or early next week. Those are going to take some time and require some brain power, patience and a lot of deep breathing.