Camper Shell Architecture - The Details! & Humaness Check In:

(Humaness Check In

Hi All,

I hope you had a good 4th of July!

I promised myself that I would post to the build thread on a weekly basis, no matter how big or small the progress. Since this is my full-time project until it is complete, and I have an ambitious build schedule, there should be enough to report on a weekly basis. In my opinion, it is nice to see some of the details that go into the build process, as opposed to just updates of the final product or outcome of the process. I spend far more time thinking about how I’m going to do something (engineering/designing/planning) than I do actually building it. Also, I want to include how the process of a project like this is impacting me personally, as a human.

I’m realizing that building an expedition vehicle is the most comprehensive project that I have embarked on in my life. It’s not that any one piece is rocket science, but the number of parts/systems/trades that you are trying to, and needing to, seamlessly integrate into one cohesive outcome, and in the lightest version and smallest space possible, is complex and can be overwhelming. I have built and remodeled homes, rebuilt centrifugal chillers, built and ran successful businesses, obtained several degrees, traveled/lived abroad for extended periods of times, trained for and completed triathlons/endurance mountain bike races, healed the existential and infinite abyss of the human psyche, and nothing compares to this project.

A one-of-a-kind prototype build can be awesome, because the sky is the limit on how you can build it. You can do whatever you want; if you can dream it, you can build! But, there is the flip side to this, not having set/established parameters, and having to make thousands of decisions-literally thousands of decisions. Sometimes trying to figure out one simple measurement requires you to consider and figure out eight other things as well. This can become maddening at times ?.

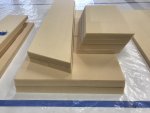

This past week, the entire week, was one of those tape measuring, number crunching, head scratching, final decision-making weeks. The types of decisions that you don’t want to SCREW UP, because they will cost you a lot of money or time in rework-if you do miss something. CF, Divinycell foam and ProSet resins are not cheap. Actually, nothing is cheap on an expedition vehicle if you are trying to build it to marine grade-ish standards. So Yah, a low level of anxiety kicked up at times, even a tinge of overwhelm ??. There were also some late nights, where I had to pause things and come back to it/them in the morning with a fresh set of eyes. By the end of the week, I was even wondering what the heck I had been doing all week, or better said, what I wasn’t doing or accomplishing all week.

Visual progress seems to be the main sign of progress and if something is not visually changing on the truck/camper, it can start to wear on me. This reminds me, I wanted to share the hardest part of the build process, to date, for me. It took me two months longer than expected to find a shop to build the rig in. It was another three to four weeks of setting up the shop, building the CF layup table/material rack and ordering CF materials. Then there was another week of designing the subframe and another couple of weeks building a mock up floor, laying out all of the cut-ins for the floor and performing initial flex tests. All of this time and work so far, months, and when I looked over at the truck, it looked exactly like the day I picked it up. All of this was also present on top of the backdrop that I was already supposed to be a year and a half into my trip, as opposed to a year and a half delayed in the trip. (Previous van build by a shop going bad, COVID shutting down the trip, break up, having to start over related to a vehicle for the trip, etc.) as the reasons for the delay.

This began to wear on me, pretty bad at times. Low energy, internal questions starting to kick up, and a bit of doubt. There were even some of those flickers and moments when I asked myself if I actually wanted to build an expedition vehicle, or even go on this trip. These moments usually occurred when I needed to take a break, eat something, or take a day off, but none the less, they were present and strong at times. The answer to these questions and doubts after things settle down, was and always is “I want to go on this trip AND in an expedition vehicle with all of my adventure gear and creature comforts”. I have to tell myself “This is what you truly want. Build this damn thing the way you want; take the time to build it the way you want. It will all be worth it in the end. If you don’t, you will regret it!” This is why seeing the mini-milestones of the subframe on the truck and floor on the subframe were wins and much needed for my moral.

(Camper Shell Architecture – The Details!)

So, after a week of tape measuring, number crunching, head scratching and final decision-making, related to the camper shell design, in particular the cab over section and cut-in boxes on the floor, I’m ready to start more CF fabrication this week. Whooo Hoooo ?!

The dimensions given for my electric steps were off enough that I had to do a bit of redesign on the step-box for the floor. I’m glad I took the time to extended the electric steps and take my own measurements. If I didn’t, I would have been in a bit of a pickle after the fabrication of the step-box, if I had used the measurements given.

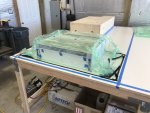

I also took the additional time to build a model of the cab over section, to scale out of cardboard, with everything located in its place. Given that I will be sleeping in this small area for at least two years, I wanted to make sure that it was what I wanted. Setting the height, and visual fields, given that there are four bunk windows, a sky light and a few custom angles, took a little time. Using CAD is helpful, but I wanted to have something to scale that I could actually lay down inside of and see/feel what it was going to be like.

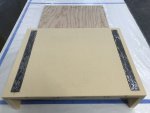

I also did not want the camper shell to be just one squared off rectangle box with a 45-degree angle on the front of the cab over. I know this is the easiest for layup and fabrication, but I want to try and give this thing some shape, without killing myself on building molds, layup, fairing and sanding. I struck a subtle balance that will give the camper shell a little shape and match angles on the truck, while also keeping the fabrication and finish manageable for me. The nose of the cab over section, as well as the two front outside corners of the camper shell front wall-just behind the cab, will match the angles on the truck.

The front corners on the hood of the truck, from a top view and a side view, as well as the vertical corners of the back of the cab, are angular, at roughly or maybe exactly 33 degrees. The back of the camper will also have a drip leg and I may put a 33 degree angle coming off the bottom edge of it as well. If I have the time and I'm feeling spunky, I may also match the camper shell to the curvature on the the back side of the cab-where the cab starts to angle forward on the back window and rounds off on the top of the cab. These subtle angles on the camper, with the addition of four custom built fairings (that will mount to the bottom edge of the camper shell in front of and behind the tires and also match the lines on the rocker panels on the truck) should be enough to tie this thing together aesthetically.

Truck angles

Cab over mock up and angles

It’s not going to be an Earth Roamer or Truck House carbon fiber kinda looking shell, but it won’t be just a box on a truck.