4307

Adventurer

Dusting of my build thread....:bigbossHL:

It's been a long winter, it was good to start building again. :wings:

Ok.... managed to do some more welding, windy day but managed to get er done.

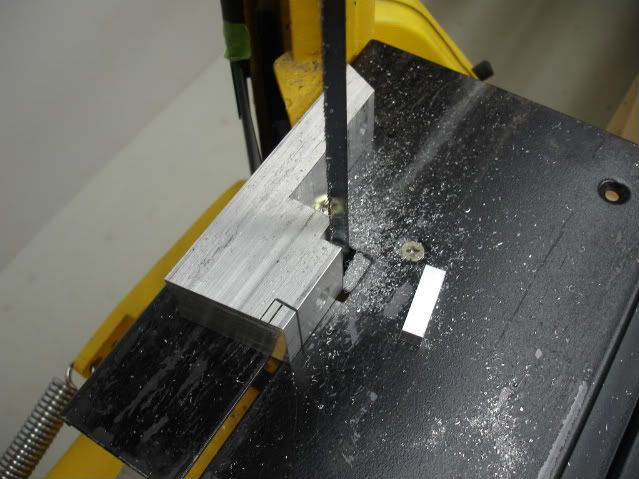

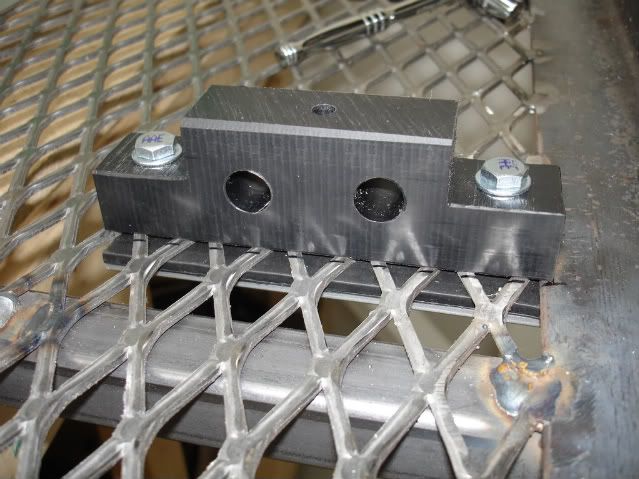

I welded the receiver gusset plate and top plate inside seam. These were the last structural welds.

The next scene in this program was adding the rock light brackets.

I used some angle iron and pieces of scrap to form the brackets, then welded them up....

Located the light brackets on the backside of the bumper, allowing for full up / down and side to side rotations for setting the perfect spot light direction. The lights will be up high enough to be out of harms way. The lights I'm mounting are 55w tractor lights, found them at Princess Auto on sale for $7.

While I was at it, I welded the Chevy leaf spring hangers together....

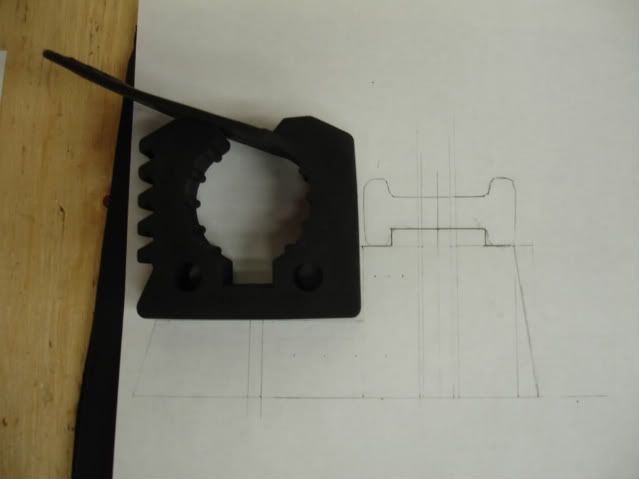

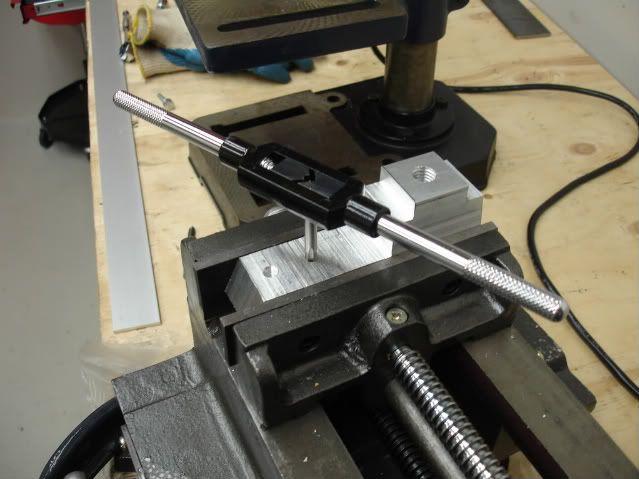

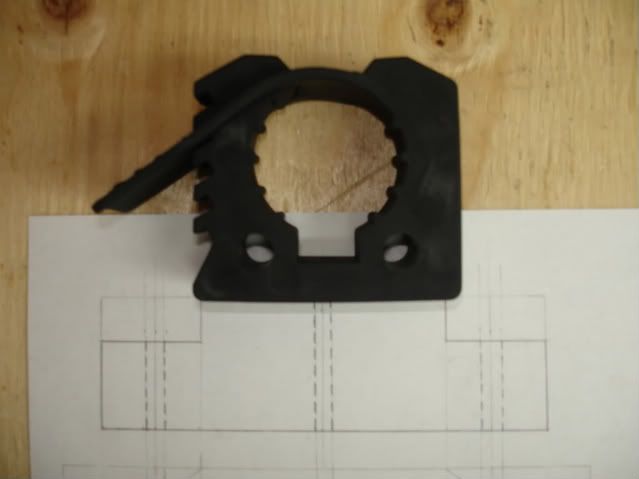

Today I decided I'm building the swing out gate.... I ordered a pair of barrel hinges rated for 600lbs.

It's been a long winter, it was good to start building again. :wings:

Ok.... managed to do some more welding, windy day but managed to get er done.

I welded the receiver gusset plate and top plate inside seam. These were the last structural welds.

The next scene in this program was adding the rock light brackets.

I used some angle iron and pieces of scrap to form the brackets, then welded them up....

Located the light brackets on the backside of the bumper, allowing for full up / down and side to side rotations for setting the perfect spot light direction. The lights will be up high enough to be out of harms way. The lights I'm mounting are 55w tractor lights, found them at Princess Auto on sale for $7.

While I was at it, I welded the Chevy leaf spring hangers together....

Today I decided I'm building the swing out gate.... I ordered a pair of barrel hinges rated for 600lbs.