Comanche Scott

Expedition Leader

I remember you posting the info on your sewing machine. Which is what prompted me to start looking for one.

I've not yet "successfully" used a sewing machine. Fortunately I have good friends willing to suffer through teaching me... lol

Looking forward to a good "winter project".

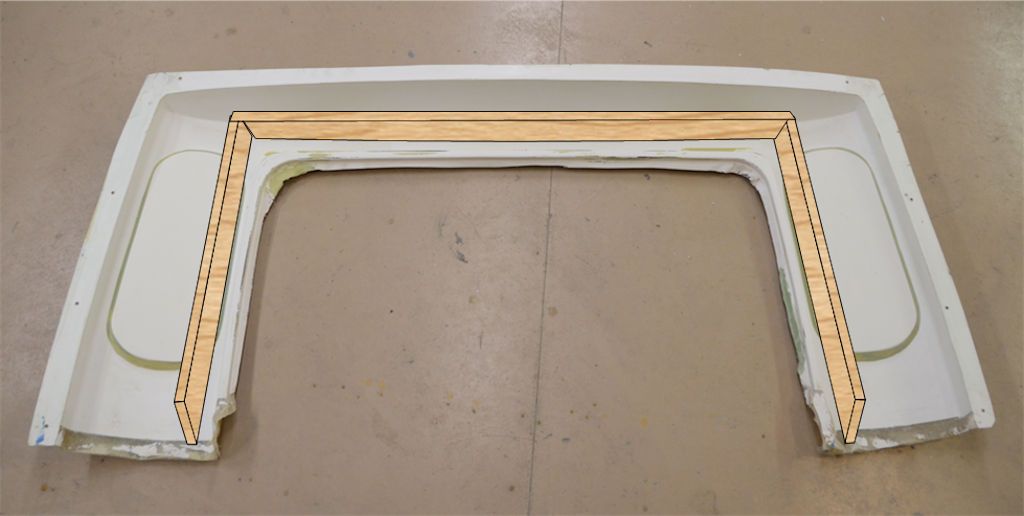

Thanks for the info on the how you made your original mold for the Barn Door. I'm going to tackle making an frp console for another build, to get some experience, and may tackle this project next spring.

Would really like to get rid of the back soft top window, and the glass hatch for the hardtop.

I've not yet "successfully" used a sewing machine. Fortunately I have good friends willing to suffer through teaching me... lol

Looking forward to a good "winter project".

Thanks for the info on the how you made your original mold for the Barn Door. I'm going to tackle making an frp console for another build, to get some experience, and may tackle this project next spring.

Would really like to get rid of the back soft top window, and the glass hatch for the hardtop.