Comanche Scott

Expedition Leader

2014; $750 w/o the wiper and harness, which could be a ~$200 option.

X2

I have no use for the wiper.

2014; $750 w/o the wiper and harness, which could be a ~$200 option.

In my particular case, the swing out carrier is so loaded, there isn't a view out the rear window.

But something just dawned on me. Can the offset rear hinges be used when the bumper has a swing out carrier?

The stock hinges are within 1/2" of hitting the spindle when fully opened now. How far do your offset hinges swing the tail gate towards the passenger side, compared to stock hinges?

Thanks. Building things for hire would take all the fun out of it, it would be a real drudge jobJsherb, I like all of the things you build and you are a good craftsman and you pay great attention to the details.

I understand why you don't build these to sell as I used to build one off wood furnature pieces for people and doing one set was a hobby, People wanted me to do more, more pieces would be would be a job.

I already had a job.

No, I've never done anything for a flatfender. Since I'm 6'6", I can't really even drive oneYou don't build anything for a '61 3B with a Koenig hard top?

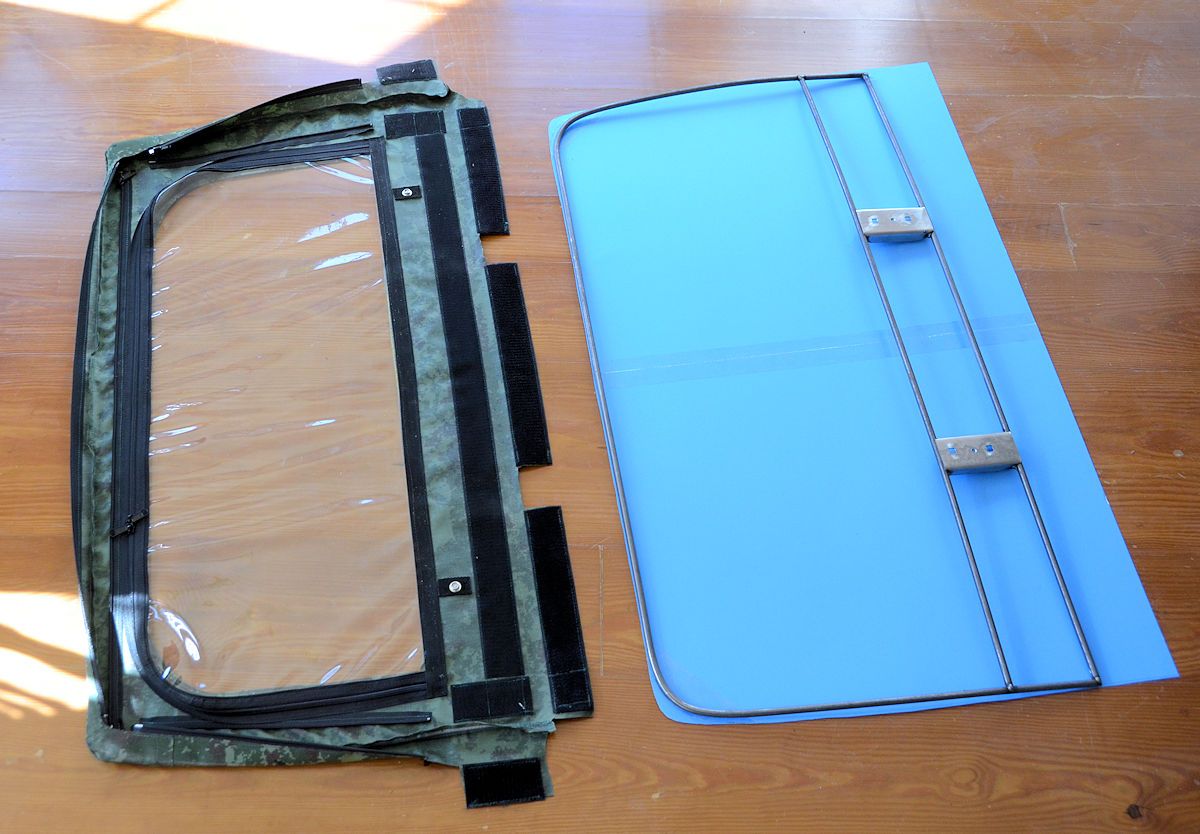

This photo shows a prototype wide-swing hinge compared to a factory hinge. The hinge pin in the wide-swing hinge is about 1" to the passenger side compared to the stock hinge pin position.

Do you glue in the zipper end stops, or use heat to "melt" them together?

I like your idea on the basting tape. Do you use that as well on the velcro to help seal the needle holes?

I traced the curves of the factory glass and transferred them to the wood I made the barn door mold masters from.Going way, way back. Did you use the OEM glass window to get the initial shape for the barn door form?

Thanks Jeff! :beer:

Sorry I missed the soldering gun. That's perfect.

I'm very interested in this portion, as I've come across a nice commercial sewing machine, and can definitely put it to use.