jscherb

Expedition Leader

Is that the same material you are going to make the soft sides with?

Looks like great quality!

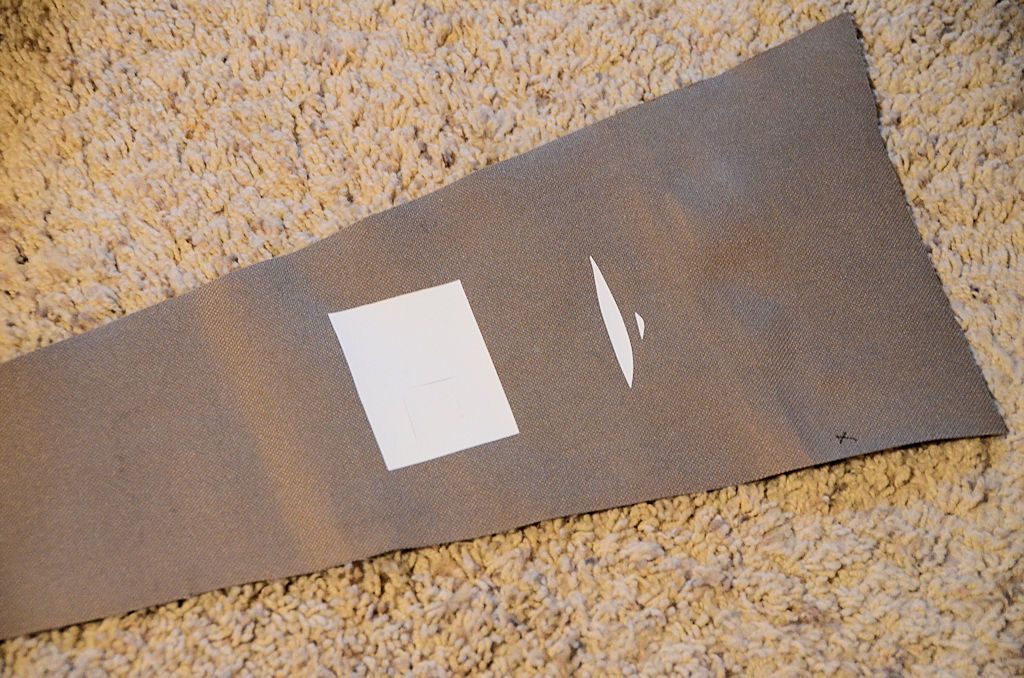

It's very different. The fabric I'm going to make the soft sides from is the exact same fabric used for factory soft tops - it's primarily polyester and it's got the factory "denim" texture. This new Cordura fabric is nylon and has a more pronounced weave texture. Being polyester, the factory fabric is more heat sensitive than the Cordura nylon fabric, which is why it's not a good candidate for heat-pressed logos. The nylon fabric is less sensitive to heat, and much stronger than the factory fabric, although slightly less UV resistant. Cordura nylon is a very high quality/very strong fabric; it's used in many military applications; I used it for my tilt-up camper project (in a different color) and it was very nice to work with:

Early in the project I discussed embroidery with the sign shop and their opinion was that because of the size of the logo it would be difficult to embroider, and being on the back of the Jeep and constantly subject to road spray/salt here in upstate NY it would attract dirt and would rarely look clean.Another possibility would to embroider in an UV stabilized thread. More money, and traps dust, but very classy when clean.

I had custom logos done for the headrests of another build at a place that does ball caps, jackets and such. Came out great, and the total was about $80-ish including the design costs.