jscherb

Expedition Leader

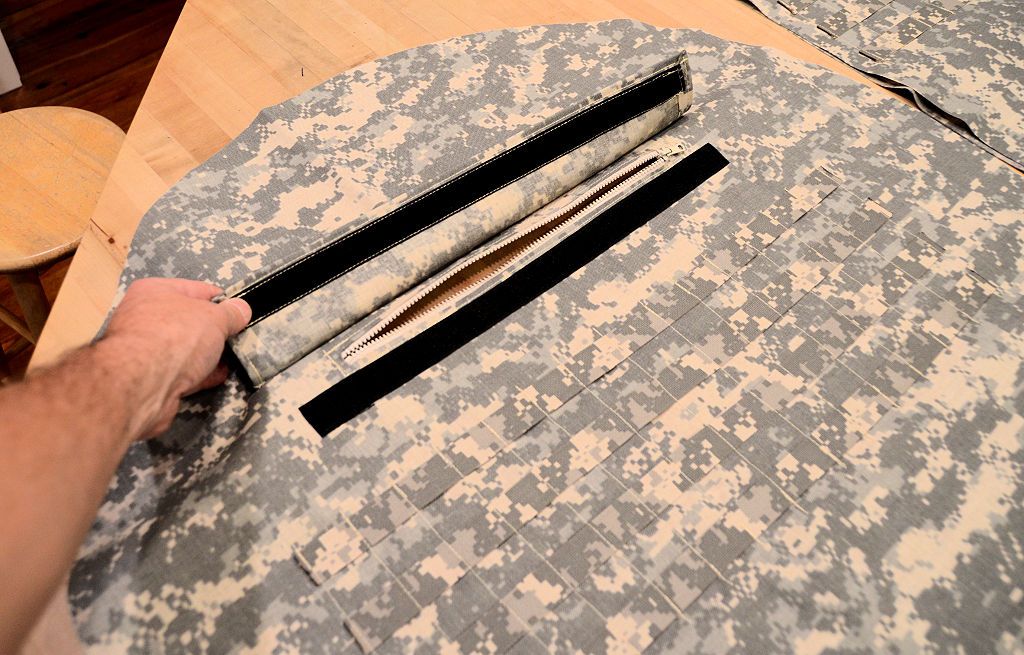

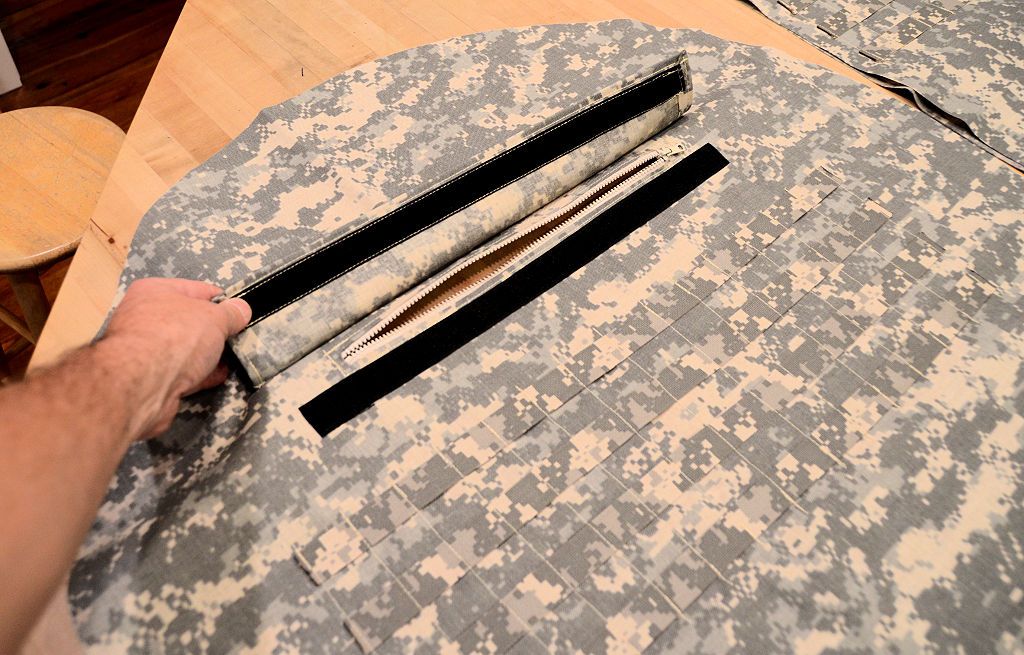

I've been pretty busy with other things but managed to get some sewing time on the "Tactical Spare Cover", I'm calling it that because in the ACU camo it reminds me of a military tactical vest. The attached photos show the progress. I haven't sewn the pocket on the inside yet, but the zipper and weatherproofing flap over the zipper is in place. There's a fairly large Molle grid below the pocket flap. There are also two small Molle grids on the outside of the cover, they'll end up at the 3 o'clock and 9'o'clock positions when it's done.