I've continued to test the wiring for the fridge and I've made a few minor updates to it, but one issue it took me a while to sort out was that in low voltage situations the fridge compressor would sometimes fail to start. When the indicated voltage was low but still above the voltage set for shutdown it would run a while and fail to restart as it cycled off and back on. Turns out is was the Dometic power plug was part of the problem - it made good enough contact in the socket to provide voltage to the fridge but not enough current could pass to start the compressor in low voltage situations. Like many such plugs, only one side is wired, so it only relies on the one contact; that contact being flat and the inside of the socket being curved, the contact area is fairly small. This isn't necessarily a criticism of the Dometic part, most of these plugs are like this, but in this case of the plug I have the contact was marginal.

I added a bit of solder to the contact to improve the size of the contact area. Works fine now. Passing this along in case anyone else needs to solve a similar problem.

I'm very pleased with the way the wiring is working. The fridge is powered by the dedicated battery when the Jeep isn't running and when the Jeep is running the fridge runs off the Jeep power and the battery gets charged.

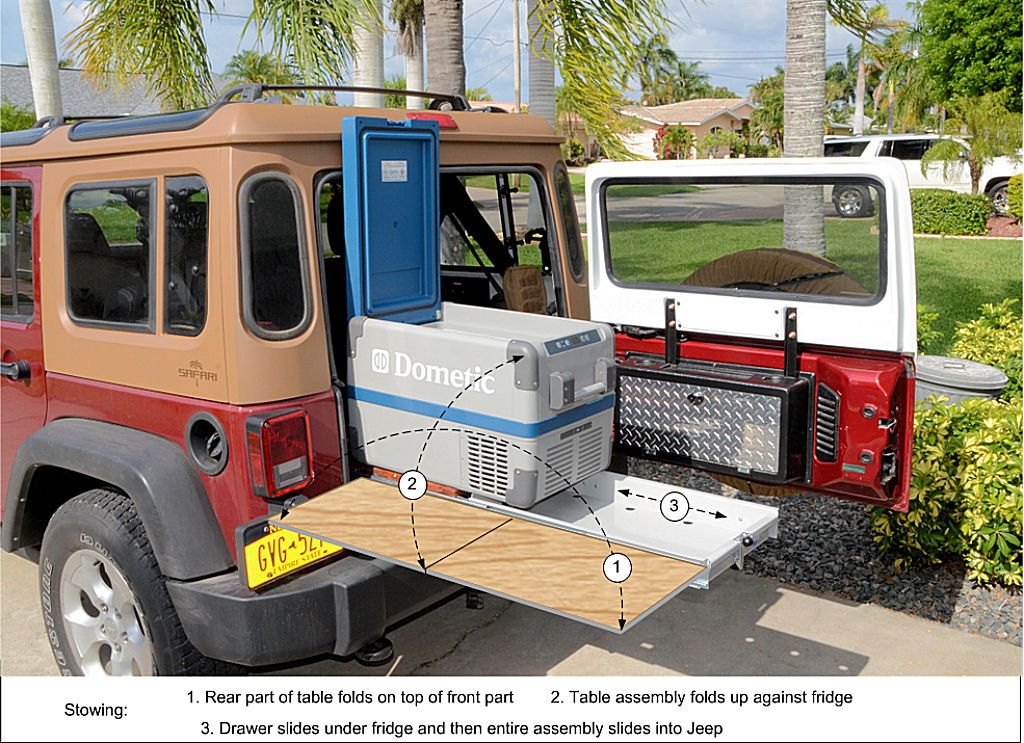

Haven't had time yet to work on the slide, mounting the fridge to it or the fold-down tables yet. I did review the fridge/slide concepts with MORryde when I ws there the other day (since they supplied me with the slide) and they were very interested in following the project for commercial possibilities. Hopefully I'll get some time at the end of this week to get back to working on the project.