jscherb

Expedition Leader

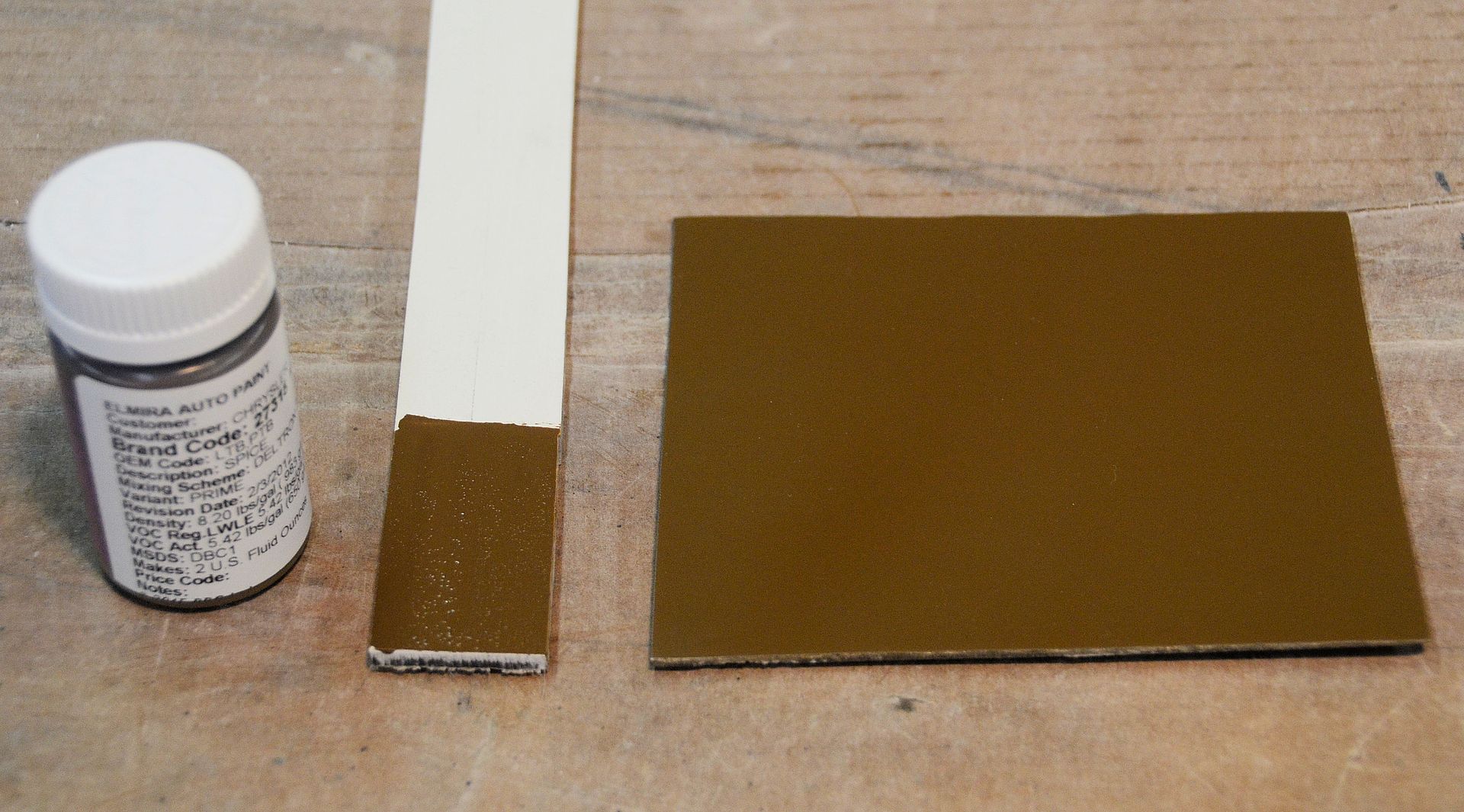

The rattle can of Spice paint arrived today, so I primed a small square of fiberglass and shot it in Spice.

The I took the square down to Elmira Auto Paint and they scanned it. Their computer decided it was a close match for Chrysler paint code LTB, which is Spice, so good news there, the rattle can matches what I can get mixed.

They then mixed me a 2 oz sample so I can compare that to the rattle can.

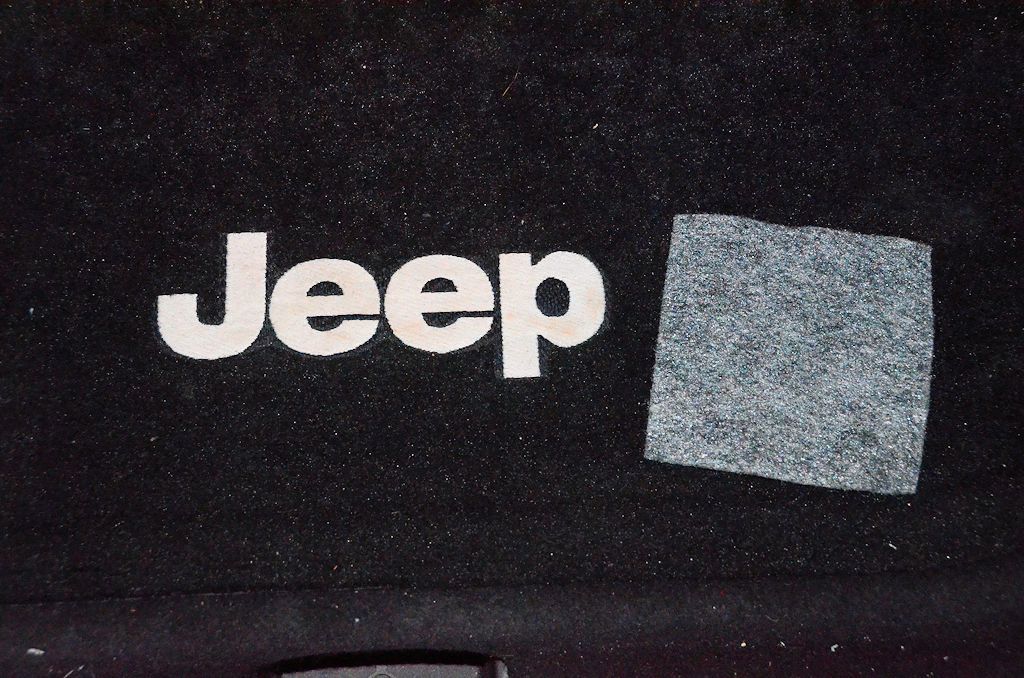

I like the look of the Spice with the Cherry Red JK, but more importantly, Heather approves.

The I took the square down to Elmira Auto Paint and they scanned it. Their computer decided it was a close match for Chrysler paint code LTB, which is Spice, so good news there, the rattle can matches what I can get mixed.

They then mixed me a 2 oz sample so I can compare that to the rattle can.

I like the look of the Spice with the Cherry Red JK, but more importantly, Heather approves.