Adventurous

Explorer

Given how much the wife and I travel into the backcountry alone I figured it was about time to install a winch. While a Warn Zeon would be nice, it wasn't in the budget, so a Smittybilt X20 Comp 10K had to do. I went with the wire rope for now.

The install has raised a few questions for me however. For those of you who have installed a winch into an ARB bumper for an 05-15, are you supposed to install the upper bolt for the fairlead? Currently it's only fastened using the 3/8" bolts for the lower winch mounts.

Secondly, I don't feel comfortable wiring the winch directly to the battery. Given that a short could potentially burn the truck to the ground, I'd rather fuse it. I'm currently considering using a 400A ANL fuse and maybe a battery cutoff to cut power to the winch when it's not being used. Anyone have experience in this realm?

Lastly, I'm going to relocate the solenoid under the hood or somewhere it's protected. I'm not too keen on having it hanging out on the front of the bumper for anyone to fiddle with. What gauge cables do you guys use? It appears that the winch is supplied with a 2 gauge which given the max amp draw of the winch seems a bit light duty. I was thinking something in the neighborhood of 2/0 gauge sounds more appropriate. Thoughts?

Quoting myself as I just got off the phone with Smittybilt and got answer to question 1.

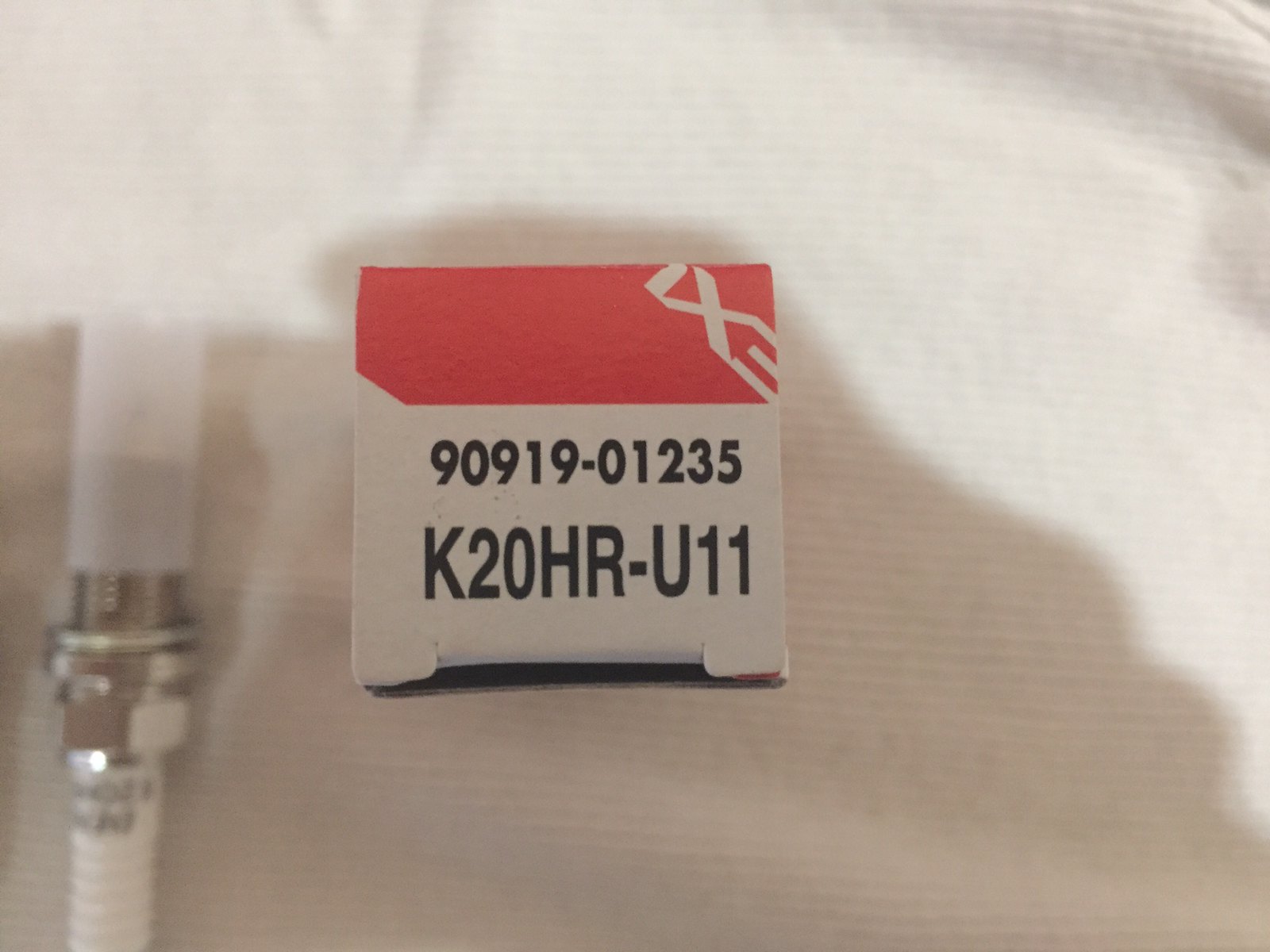

The two lower bolts that mount the winch also attach the fairlead. Now, the confusing part comes that they are specified as 3/8"-16 bolts with 10.9 stamped on the head. Grade 10.9 bolts don't exist in SAE threads, only metric. According to Smittybilt anything grade 5 and above is adequate, so I shall replace those lower bolts with some slightly longer ones in Grade 8 and that will more than suffice for the application. I shall however ignore the fact that they have obtained the unobtainable.