Great work Jeff. How did you cut the angle on the inside of the corner piece?

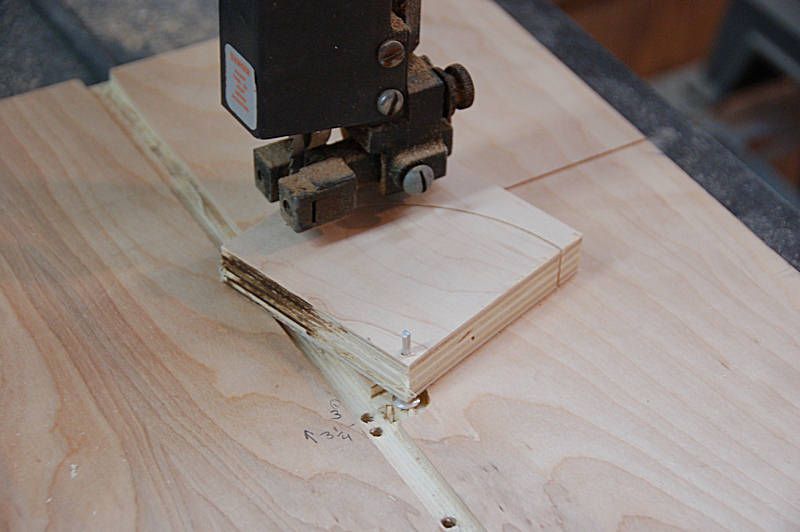

I cut the corners on a bandsaw. Shown in the first photo below is a circle-cutting jig I made for my bandsaw (I didn't make it just for this project, I also used it to cut the larger half circles for the small inner fenders I did about a month ago). It's got a pivot pin on which the wooden blank spins to cut circles. The blank is a piece of wood with a hole drilled in one corner that goes over the pivot, and there are two blanks for each corner.

Next photo shows a blank being cut, I stopped mid-cut to take the photo. The blank is being rotated clockwise into the blade.

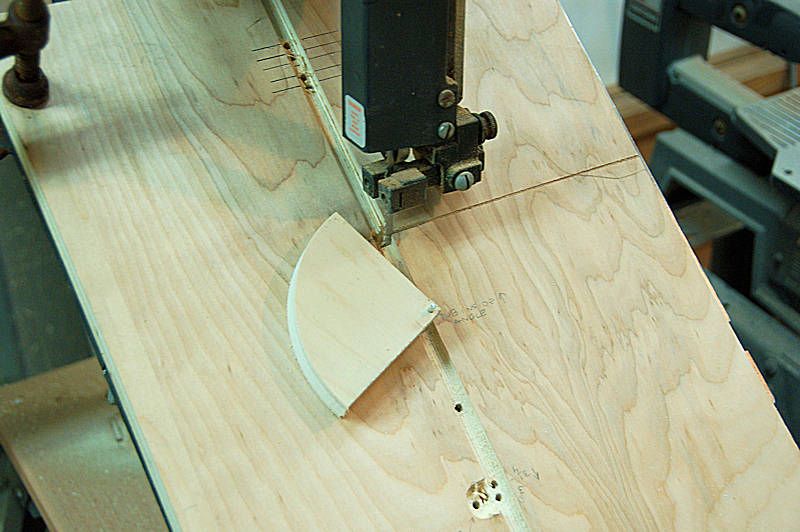

One of the blanks for a corner only gets that one cut, but the second blank also needs an angled cut on the inside. That's done with the same jig, but with the bandsaw table set at the same angle as the angle on the edge of the tub, and the pivot pin in a different position to make a smaller radius. Here's how it looks with the blank in place setting up to make the cut:

And here's a shot after the cut. I've set the cut piece against the blade so you can see how the angle gets cut:

Once the two parts are cut, they're glued together. The 90 degree corner is cut off at a 45 degree angle. A small roundover bit in the router is used to knock the sharp edges off (the router is mounted in a router table to make routing on such a small piece safe). A slot is cut in the angled edge to accept a wooden biscuit, which is used to join the corner to the main platform.

Finish up with a little light sanding and that's all there is to it.

)

)