I'm now working on an updated mold for a tailgate inner skin that can be set up in either drop-down or side-swinging configuration, with outside lock/latches. Here's a paper mockup of the side-swinging configuration (ignore the actual CJ hinges at the bottom of this taiglate):

This mockup uses CJ tailgate hinges mounted on the side, and an outside t-handle latch.

The inner tailgate skin will have recesses to accomodate the hinge bolts for the side-mounted CJ hinges. I'll do the recesses on both sides, so the tailgate could be configured to swing open from either the left or the right.

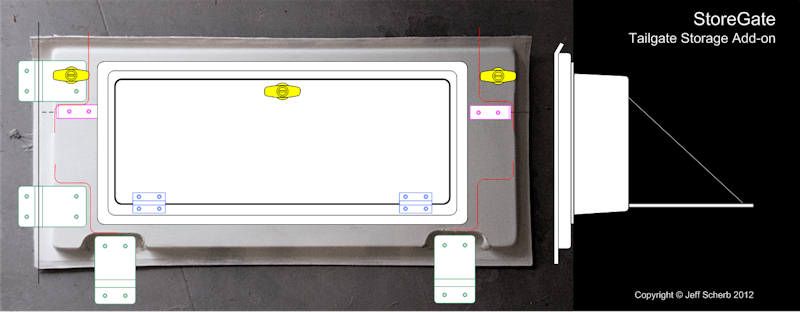

This photo/drawing shows positions of hinges and latches for both the drop-down and the passenger-hinged side-swinging (most of the hardware is pictured on the inside, when it actually goes on the outside, this is just for illustrating the placement of the hardware relative to the inside skin of the tailgate):

Doing this, it's possible to mold one tailgate that could be configured to be drop-down, left-opening side-swing, or right-opening side-swing.

Also, I've got samples of both t-handle and flush latches for this new tailgate; here they are mounted in a test piece of fiberglass:

I think they're both really good choices for the tailgate, just depends on which style you like better. I've worked out the new tailgate design so it will support either one of these, in either drop-down or side-swing configuration.

And one more thing... I'm also finalizing the design for something I call the "StoreGate", it's a fiberglass storage add-on that could be used with these tailgates, or with Jeep factory tailgates on the trailer or your Wrangler:

I don't know when/if I'll make the molds for the StoreGate, but I'm finalizing the design details so it could be made if I decide to make it.