You really are a man with a plan, that executes accordingly. There seems to be no limit to what these trailers can be made to do!

+1000

You really are a man with a plan, that executes accordingly. There seems to be no limit to what these trailers can be made to do!

For anyone who might want to remove their RTT every so often, you might consider mounting it to two cross rails slightly above the cover. RTT's have two c-channels that can be mounted (and removed) fairly easily. But you need a hand's worth of clearance to reach in and unbolt. This would also give you a bit more room to reach in to your trailer with the tailgate down.

For anyone with a kayak, you could extend the rack up above the RTT in the front and rear to allow the hull to clear. This might get a tad top heavy for anyone traversing a black diamond trail, but i bet it gets you to most watering holes.

Rails also make great locations for tying off or securing awnings, canopy poles, ropes, etc when the trailer is stationary.

Apologies for the crude photoshop hack.

View attachment 86972

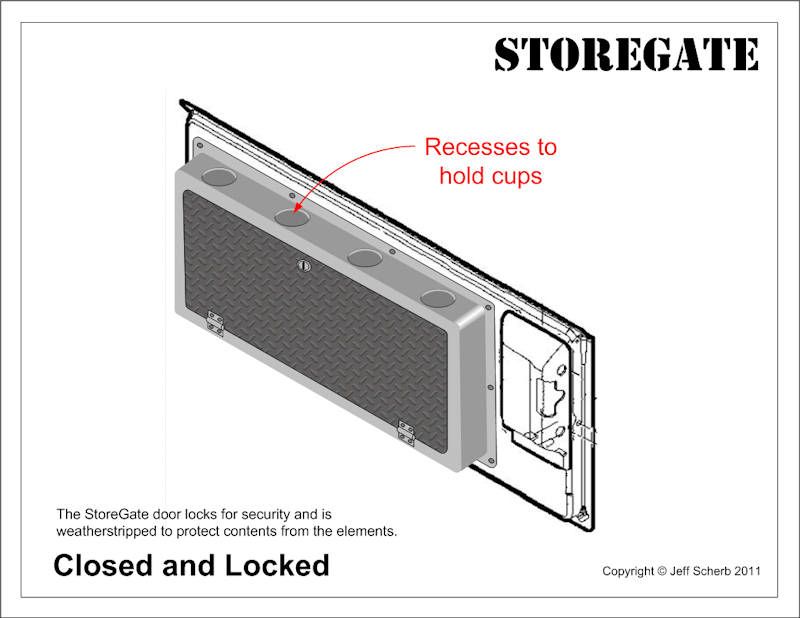

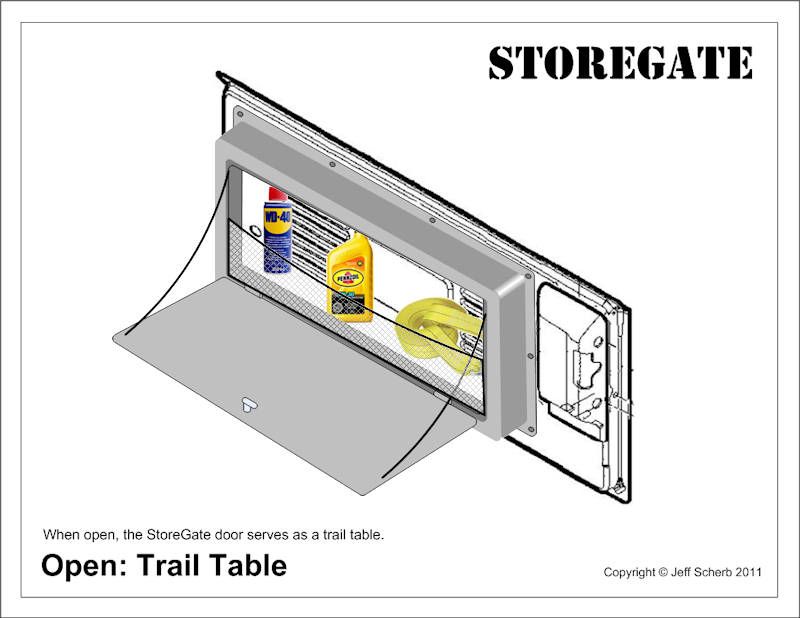

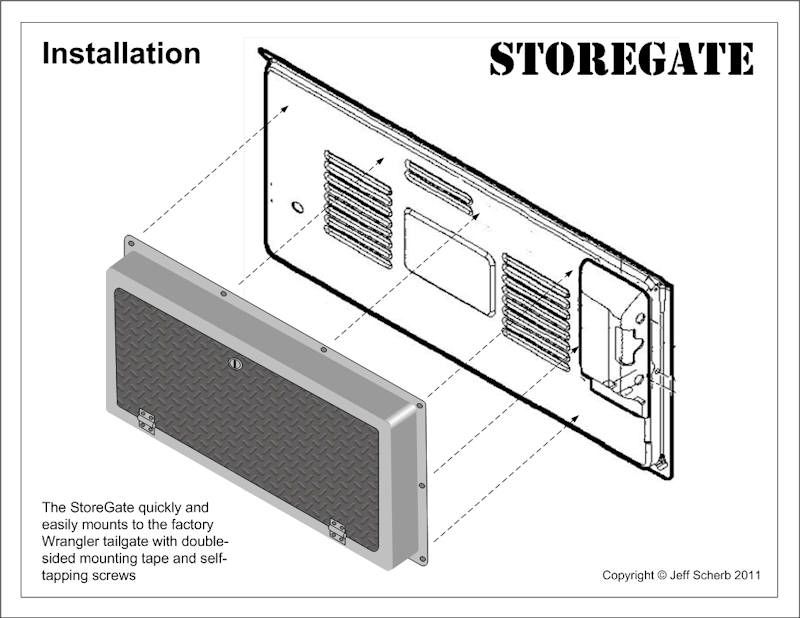

Yes, I have designed it to fit the factory Wrangler tailgate as well as my fiberglass tailgate.Will this Storegate be able to be retrofitted to a factory wrangler gate? If so, you will have a whole new product to market. A JK version would be pretty sweet as well.

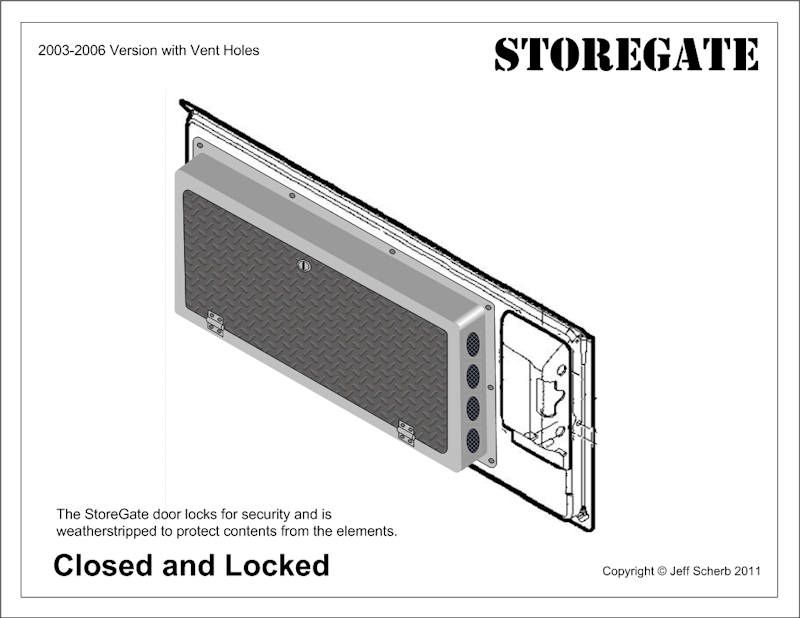

I almost feel ashamed to make any suggestions on your work / design since everything you make turns out so nice, but... maybe the vents could be placed on the bottom of the Storegate to make it easier to keep out the elements. It would also allow it to drain more freely if something like a water bottle leaks. I'll certainly add this item to my wishlist along with the trailer tub kit and exogate.