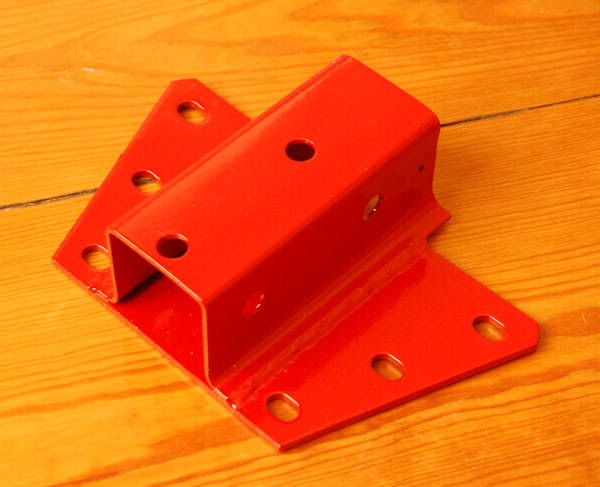

When I unpacked the Harbor Freight trailer two weeks ago to check it for completeness, it was missing a key part - the coupler mount. I called them right away and no questions asked, they sent a replacement, and it showed up the other day. Here it is:

And here's how it mounts on the tongue of the trailer, and how the coupler mounts:

Seeing this gave me an idea... thinking back to this comment made a week ago:

...there are several styles of articulating hitches on the market that require a receiver mount up front rather than a bulldog or similar. You might want to look at that option as well as a ball hitch will not work all that well offroad.

The shape of the HF coupler mount reminded me a lot of the common bumper mount receivers available for pickup trucks, so I stopped by Tractor Supply this morning and picked one up. It can be adapted very simply into a front receiver for the trailer to accept the type of couplers the person who made that comment was talking about.

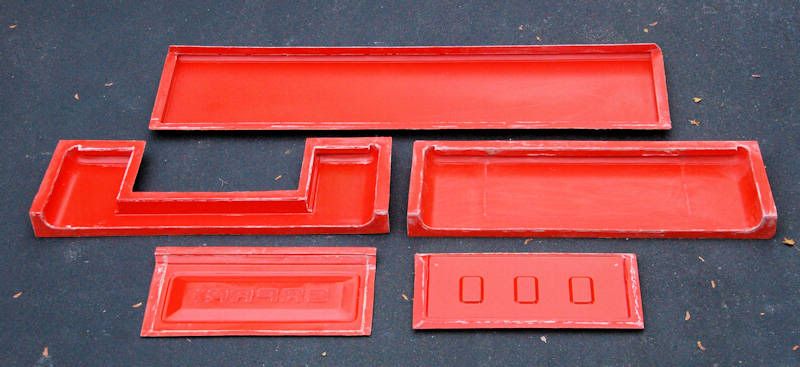

Two of the holes already line up, so only two more holes have to be drilled, although the bumper receiver shown above probably isn't optimal for this application, it's the only one I could find in town this morning - the slightly wider HF 67185 receiver below might be better:

These HF ones can typically be picked up for about $20 when they're on sale and using the 20% off coupon.

So for about $20 the HF trailer can be converted to a receiver coupler mount to accept high-angle off-road couplers or an eye coupler for a pintle hitch. No welding, just a little drilling.

You could also could pick up a short length of 2" square tubing and mount a standard ball coupler to it so you could easily swap between a ball coupler for on-road use and a pintle eye for off-road use.