jscherb

Expedition Leader

How are you planning to mate the bed to the sides? I was thinking of doing something like this. I am surprised that know one has done this sooner.

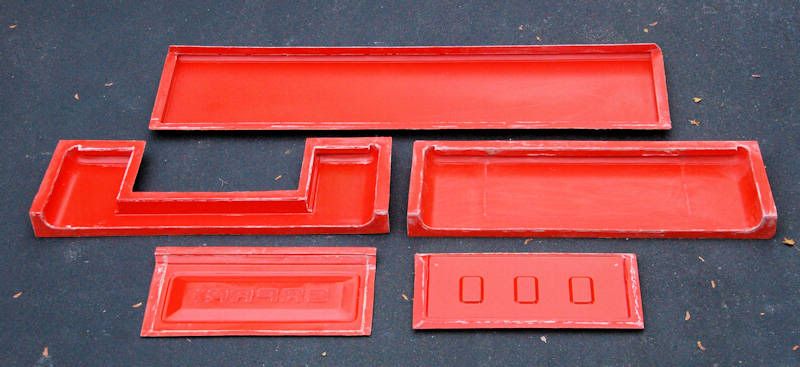

There will be a flange molded into the inside of the side panels; the sides will bolt to the floor through that flange; the flange will rest on top of the floor. The flange will be similar to the flange on the inside of a typical Jeep hardtop. I'll post photos of the sides-floor assembly when I get to that point in the build.

About the floor... since this kit is designed to be an affordable, buildable by a DIY-er in his driveway with ordinary tools on a tight budget, the entry level floor choice will be plywood. You'd seal it with a good exterior wood sealer, after which it could be painted or shot with DIY bedliner.

But the flange will also be compatible with standard pickup bed floor systems from the 30's through the 80's, so if you wanted to do something fancy, you could do bed wood like this (also note the "angle strip" spot-welded to the inside of the bed side, it is used to bolt the bed sides to the floor, just like the fiberglass flange that will be on the tub kit sides):

BTW, that's not wood in these photos, it's TimberTech plastic decking. Essentially zero maintenance, looks great.