jscherb

Expedition Leader

Brute on a Budget...?

I'm on my way to Las Vegas now, I'll be attending the SEMA show starting tomorrow.

But in the meantime...

It's no secret that I like building Jeep pickup trucks - I've built two so far:

One of the reasons I've been doing this fiberglass trailer tub kit project is to serve as a proof-of-concept test for a fiberglass pickup bed, for a possible future pickup project I'm considering.

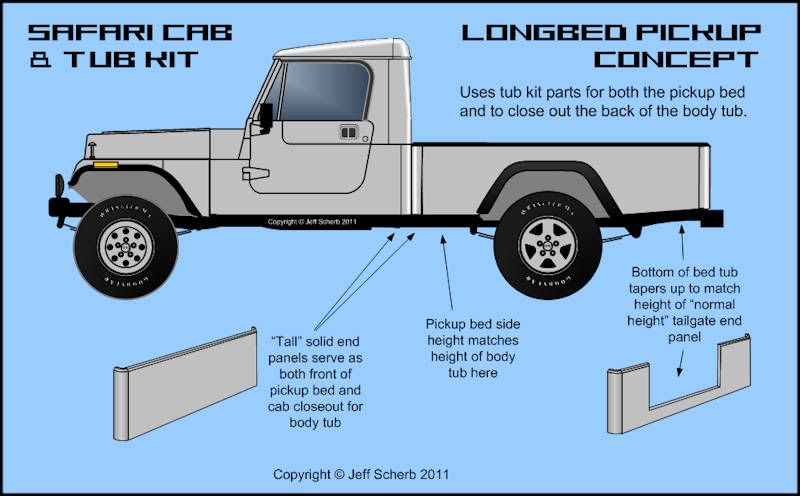

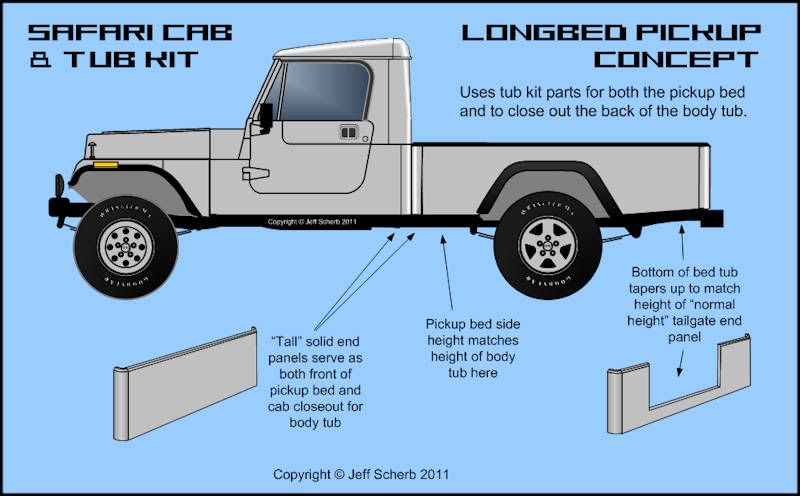

Here's a concept drawing showing the tub kit parts being used both to make the back wall of the body tub and the pickup bed tub, and of course a Safari Cab half cab...

Taller solid end panels serve as both the rear of the body tub and the front of the pickup bed; I haven't made the mold for these taller solid end panels yet, but it's a simple modification to the current solid end panel master. This fiberglass panel can easily be bolted/bonded to the back of the cut off tub to complete the pickup cab tub, it would be a much easier tub conversion than trying to shorten a tub by cutting something out of the middle and trying to weld the original back panel in place behind the front seats.

The side panels for the pickup bed would be molded with an angled dam in the rear to slope the bottom of the bed side up to meet the standard height end panel with the tailgate opening in it, the same way the bottom of the Jeep tub slopes up behind the wheel wells.

With these parts you could build a "Brute on a Budget". The Brute cab closeout sheet metal from AEV is about $2300, but this fiberglass end panel closeout could be sold for a small fraction of that (a few hundred bucks probably). The Brute pickup bed from AEV is $5500; this fiberglass one could also be a small fraction of that. Add a Safari half cab hardtop or a Gr8Tops half cab hardtop, and some lengths of frame rail from the junkyard to length the frame and you're pretty close to everything you need to assemble a pretty cool Wrangler or CJ based pickup...

The drawing above is a "longbed" concept, but of course the pickup bed tub could be made to any length.

I'm on my way to Las Vegas now, I'll be attending the SEMA show starting tomorrow.

But in the meantime...

It's no secret that I like building Jeep pickup trucks - I've built two so far:

One of the reasons I've been doing this fiberglass trailer tub kit project is to serve as a proof-of-concept test for a fiberglass pickup bed, for a possible future pickup project I'm considering.

Here's a concept drawing showing the tub kit parts being used both to make the back wall of the body tub and the pickup bed tub, and of course a Safari Cab half cab...

Taller solid end panels serve as both the rear of the body tub and the front of the pickup bed; I haven't made the mold for these taller solid end panels yet, but it's a simple modification to the current solid end panel master. This fiberglass panel can easily be bolted/bonded to the back of the cut off tub to complete the pickup cab tub, it would be a much easier tub conversion than trying to shorten a tub by cutting something out of the middle and trying to weld the original back panel in place behind the front seats.

The side panels for the pickup bed would be molded with an angled dam in the rear to slope the bottom of the bed side up to meet the standard height end panel with the tailgate opening in it, the same way the bottom of the Jeep tub slopes up behind the wheel wells.

With these parts you could build a "Brute on a Budget". The Brute cab closeout sheet metal from AEV is about $2300, but this fiberglass end panel closeout could be sold for a small fraction of that (a few hundred bucks probably). The Brute pickup bed from AEV is $5500; this fiberglass one could also be a small fraction of that. Add a Safari half cab hardtop or a Gr8Tops half cab hardtop, and some lengths of frame rail from the junkyard to length the frame and you're pretty close to everything you need to assemble a pretty cool Wrangler or CJ based pickup...

The drawing above is a "longbed" concept, but of course the pickup bed tub could be made to any length.