Okay, so the turbo project is starting properly this weekend. The 6bg1 in standard form is 120kw and 431Nm. Yawn.

After way too much research and time hunting down parts, this is what I've put together:

If you are looking at a turbo conversion using the Hx35, the compressor housing is huge. You really need to consider if you have enough room. The first part of this job for me is working out how to make it fit.

I still need to get an intercooler and the oil supply and return lines, but I'll get these made once everything else is fitted.

I'm still trying to find someone with a dyno that's large enough who will do a run pre conversion. All the tuning guys seem to be a bit precious about old trucks, and seem to only be interested if they can sell you a chip or remap. This is a problem I wasn't expecting to have if I'm honest.

After way too much research and time hunting down parts, this is what I've put together:

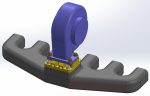

- HX35w turbo

- V-band clamps for turbine and compressor housings

- V-band flanges

- Manifold of a 6bg1tq

- Lots of hose clamps

- Lots of silicone bends and tube

- 316 2.5" tube for the intercooler pipe

- 316 3" tube for the exhaust dump pipe

- 30mm 316 plate for t4 to T3 adaptor (turbo is T3 and manifold is t4)

- 316 5" tube for snorkel

- 316 4" tube for air filter to turbo

If you are looking at a turbo conversion using the Hx35, the compressor housing is huge. You really need to consider if you have enough room. The first part of this job for me is working out how to make it fit.

I still need to get an intercooler and the oil supply and return lines, but I'll get these made once everything else is fitted.

I'm still trying to find someone with a dyno that's large enough who will do a run pre conversion. All the tuning guys seem to be a bit precious about old trucks, and seem to only be interested if they can sell you a chip or remap. This is a problem I wasn't expecting to have if I'm honest.