You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

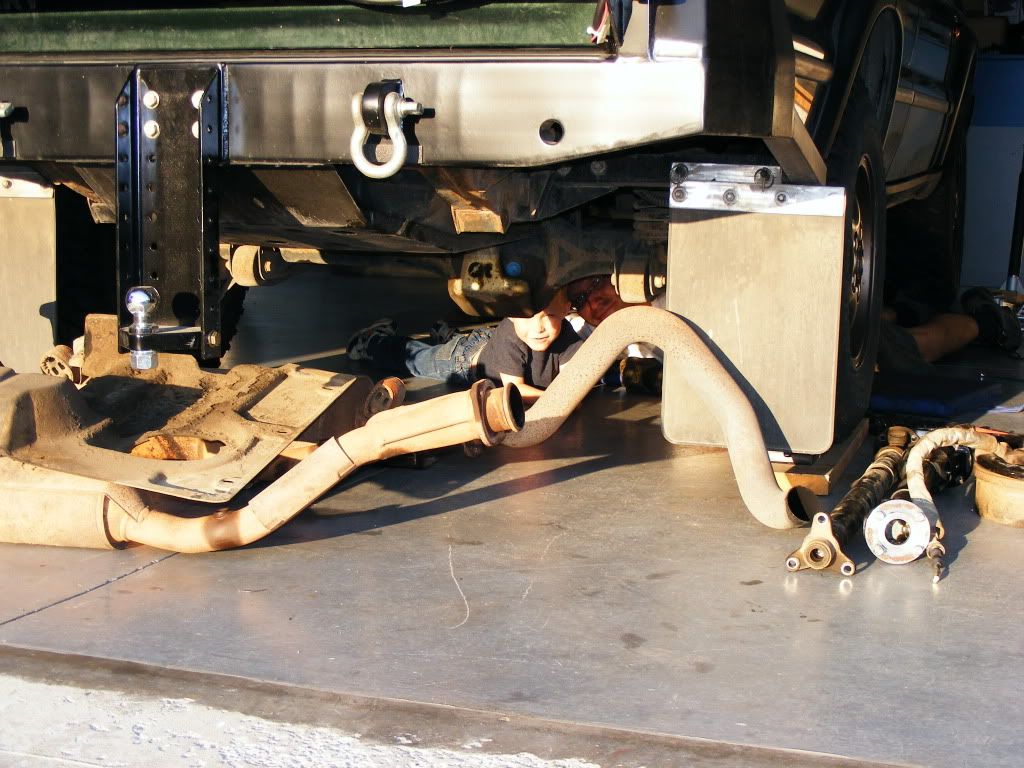

Canadian Disco 2 Build

- Thread starter R_Lefebvre

- Start date

R_Lefebvre

Expedition Leader

Did you tip the powertrain down? Mine absolutely would not come off the shaft with the powertrain in the normal position. It hit the back of the trans tunnel and the front of the muffler heat shield before it was off the shaft. I won't try to put it back up the same way.

A guy at work has a trans jack he'll lend me, so that's one problem gone.

A guy at work has a trans jack he'll lend me, so that's one problem gone.

Antichrist

Expedition Leader

I defintely would have made the tool from RAVE.

If it works as well as the one for the R380/LT230 it would have made life a lot easier.

If it works as well as the one for the R380/LT230 it would have made life a lot easier.

Did you tip the powertrain down? Mine absolutely would not come off the shaft with the powertrain in the normal position. It hit the back of the trans tunnel and the front of the muffler heat shield before it was off the shaft. I won't try to put it back up the same way.

Remove the front and rear dshaft. Remove the rearmost x-member, remove the y-pipe exhaust.

Undo all bolts, shifters, breather hoses, plugs, transmission bolts, fuel line snaps, etc.

Undo t-case mounts and it should come out rather easily. Thats how we drop in different tcases into 03 non CDLs

-Sam

R_Lefebvre

Expedition Leader

That's exactly what I did Sam. But it ran into the back of the trans tunnel before it was off the shaft? It wouldn't come off clean unless I removed the left hand side mount to let the whole powertrain tip down. But it was too late by that point. I thought maybe it was because the ZF24 is a bit longer than the 22, 1/2" would have helped a lot. But then I tried lining up where the R380 will sit based on it's motor mount, and it looks like it'll end up about the same?

Tom, I never saw that. I might do that to put it back up. Having the centering point for the jack is nice.

Tom, I never saw that. I might do that to put it back up. Having the centering point for the jack is nice.

Did you tip the powertrain down? Mine absolutely would not come off the shaft with the powertrain in the normal position. It hit the back of the trans tunnel and the front of the muffler heat shield before it was off the shaft. I won't try to put it back up the same way.

A guy at work has a trans jack he'll lend me, so that's one problem gone.

you need to drop the exhaust.

I have dropped a number of DII TC's without having to do anything with the engine or trans mount.

I defintely would have made the tool from RAVE.

If it works as well as the one for the R380/LT230 it would have made life a lot easier.

I have one of those that drops into my floor jack and has a single bolt to hold it in place up from the bottom through.

I built it when I first did my trans years ago and it has come in VERY handy ever since.

R_Lefebvre

Expedition Leader

you need to drop the exhaust.

I have dropped a number of DII TC's without having to do anything with the engine or trans mount.

The entire exhaust is on the floor behind my truck.

The TC hit the back of the trans tunnel sheet metal, and the muffler heat shield which is still attached to the body.

There have been a number of differences between my truck and what the Rave says to do. First, it says nothing about disconnecting the diff lock cable, but that part was obvious. I've got the C clip holding the hi/low cable on that cannot be undone from underneath. And I don't have a zip tie holding my fuel lines needing to be cut. I actually have a bracket holding the fuel lines to the TC with a ************* bolt that took 30 minutes to get out because it's blind, no room to get a 1/4" drive ratchet in, and you have to turn it a couple degrees at a time.

I actually have a bracket holding the fuel lines to the TC with a ************* bolt that took 30 minutes to get out because it's blind, no room to get a 1/4" drive ratchet in, and you have to turn it a couple degrees at a time.

Get an extension, pass it above the frame rail. Easy peasy.

Dont bother trying to get it back on though. Took me a long time to try and get the bolts to line up again. Wound up going in at an angle and stripped the threads.

-Sam

On a side note, I dont usually run into half the problems that you have run into. Just some issues here and there that can be overcome with a grinder or a big hammer.

I dont think my knowledge or skill level is anywhere near where it needs to be to tackle a project the size and scope of yours. I would never have the balls to attempt a project like yours. But the more i follow this thread the more confidence(famous last words) I have to tackle bigger projects...

How's your comfort level sitting now that you are deep into the project?

-Sam

I dont think my knowledge or skill level is anywhere near where it needs to be to tackle a project the size and scope of yours. I would never have the balls to attempt a project like yours. But the more i follow this thread the more confidence(famous last words) I have to tackle bigger projects...

How's your comfort level sitting now that you are deep into the project?

-Sam

R_Lefebvre

Expedition Leader

Get an extension, pass it above the frame rail. Easy peasy.

Yeah, I thought about that. But there's some other pipes or hoses jamming up that space. Not even sure what they are. Not the fuel lines. They're like 1/2" OD. For some reason, there was a wiring harness or something wrapped around them. I had to unsnake it and it was a PITA. Maybe it was the TC cables. I can't remember, but I had to unsnake it and I was like "****** did they do that for?!"

It's frustrating. Generally speaking, the truck is pretty easy to work on. Everything is so simple, and fairly easy to understand. But then some of the things they did are totally ******. Frankly, it seems to be the more recent additions. No concern for servicabililty. Which actually isn't surprising these days, that's how all cars are. I remember trying to make changes at Ford, and the service engineer was always bugging me, and I was like "Get lost the plant needs the fix!"

On a side note, I dont usually run into half the problems that you have run into. Just some issues here and there that can be overcome with a grinder or a big hammer.

Actually, I think I'm ahead of schedule. I knew the crossmember would be a PITA. I knew the exhaust would be a PITA, but the nuts on the exhaust manifold coming off easy was a big bonus. I was prepared for those to be ****ed and then... OMG. I've struggled with a few things, but then all the bolts came out of the TC no problem, and it popped off without needing to be "persuaded" to release from the ZF. I do wonder why my LT wouldn't clear the sheet metal when everybody else says it does. I notice there's a slot in the engine mounts, but mine were fairly well centered.

I dont think my knowledge or skill level is anywhere near where it needs to be to tackle a project the size and scope of yours. I would never have the balls to attempt a project like yours. But the more i follow this thread the more confidence(famous last words) I have to tackle bigger projects...

How's your comfort level sitting now that you are deep into the project?

Well, maybe I'm naive, but I'm more confident now than when I started. I built a turbo system from scratch and put it on a car that never had a turbo, and that's still alive, I think I can handle this.

But I'm glad I'm using all factory parts. And new parts, no junkyard junk. And I'm glad that Lucky8 has already (almost) done this. The only thing I'm concerned about is the ECU. I'd rather not have the CEL on permanently.

If Justin hadn't already done this successfully, I wouldn't have attempted it.

Well, maybe I'm naive, but I'm more confident now than when I started. I built a turbo system from scratch and put it on a car that never had a turbo, and that's still alive, I think I can handle this.

What engine management? The exhaust plumbing and the IC piping, etc is relatively straightforward. As is adjusting the FPR and dropping in a new set of injectors. Its the tuning that gets complicated.

I used to own a MkIV 1.8t VW, over 400hp at the wheels. With the exception of cams stock from oil pan to valve covers. Gt28 dual bb turbo. Unfortunately my other boosted cars werent factory boosted and posed much greater challenges.

-Sam

R_Lefebvre

Expedition Leader

Garrett GT28R

42lb Injectors

Spearco Air-Water intercooler

scratch made swirl pot

OEM Lightning intercooler water pump

custom marine silicone rad hoses

Forge Motorsport blow off valve

Random Tech high flow cat.

That is an old pic with an Aerocharger hanging off the factory manifold with a custom adaptor and downpipe. Eventually that turbo failed, so I put the Garrett on. At first I used a beautiful polished SS Xios Motorsports intake manifold, but that failed catastrophicaly on the first trackday. Now I'm using a basic weld-el log manifold.

Fuel system is returnless, so no FPR to play with. I've got a Pectel T2 ECU with a Motec PLM wideband. It's an amazing ECU with all the features, even closed loop idle control and data logging. Full control, the factory ECU only runs the speedo now. I've tuned it well enough to pass emissions, but barely. The setup has seen the other side of 25psi when the boost signal hose failed. Still running strong on the original powdered metal connecting rods which is somewhat of a miracle.

Quiafe differential, still rocking the original clutch. But I don't drag race. It holds fine, but it won't take a drag launch.

Biltein inverted strut coilovers. These things are amazing, but the travel is too short which is a bummer. Wilwood Forged Superlight calipers and 12" rotors.

Autopower cage, and Sparco controls and belts.

[ame="http://www.youtube.com/watch?v=GQsOpcbV5yY"]YouTube- Harvest Happening 2005[/ame]

R_Lefebvre

Expedition Leader

Didn't spend too much time on it last night, but the trans is ready to come out. I had a bit of trouble getting the bolts out of the back of the flex plate. I was using a ratchet with a deepwell, but it kept twisting off. I thought that it was coming loose but I was really starting to strip the head. Took out the impact gun with a long extension and that got them out. First time I've used power tools on this job so far, I think. I don't use them very often at all anymore. The impact gun can make the fast jobs faster, but it can also make the slow jobs much slower if you destroy a stuck fastener. Luckily they actually designed the vehicle with servicability in mind in this instance as there's a nice slot in the oilpan to run an extension to the bolts.

I've ordered about $200 more parts from Rimmer Bros. that I missed on the first go. Hopefully I can get them next week.

I've ordered about $200 more parts from Rimmer Bros. that I missed on the first go. Hopefully I can get them next week.

Last edited:

Antichrist

Expedition Leader

Oddly enough, it's not in the DII manual. Or at least I couldn't find it in a quick search. It's in the "Tools" section of the gearbox chapter in the D1 manual.Tom, I never saw that. I might do that to put it back up. Having the centering point for the jack is nice.

But for reinstall, you'll want the one from the R380 section.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 26

- Views

- 6K