jscherb

Expedition Leader

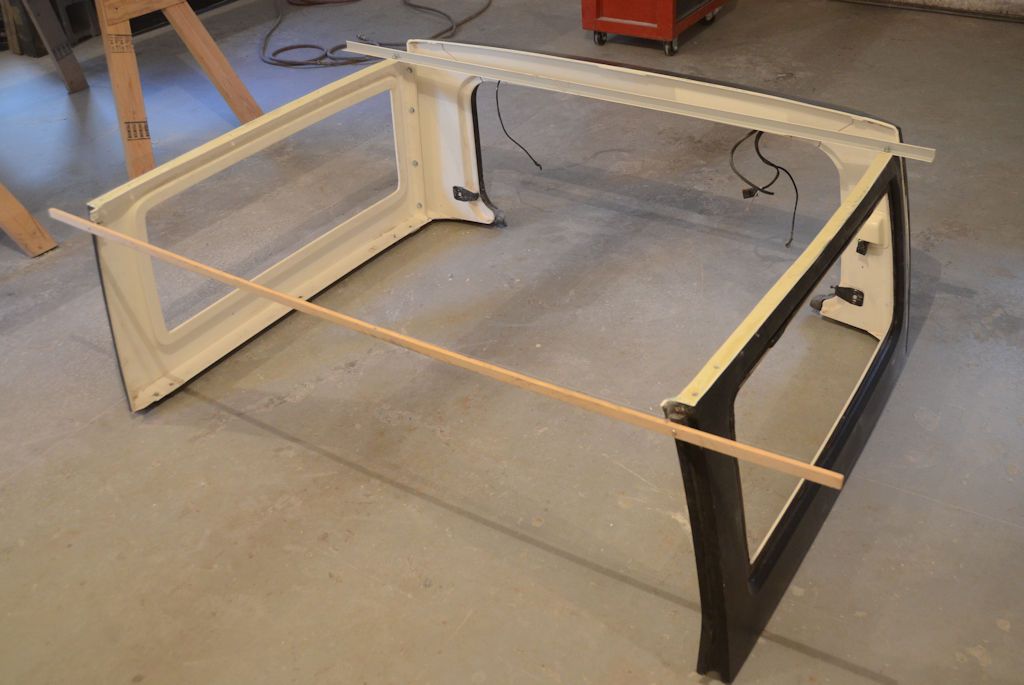

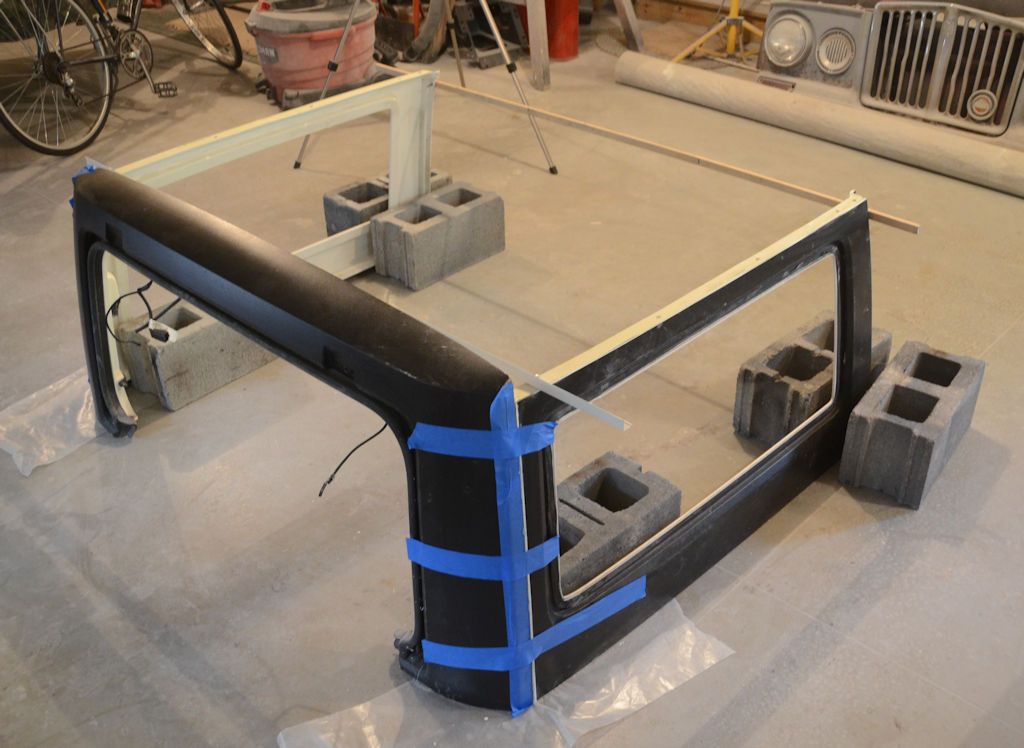

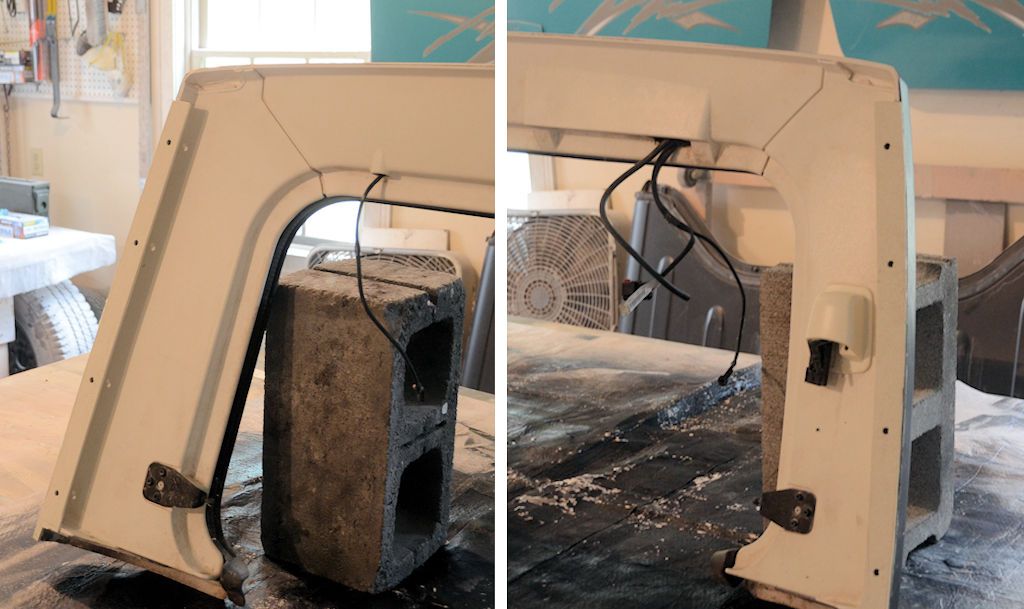

So on to layer 1, the 1" strip of fiberglass mat layer applied with SMC-compatible resin...

Catalyzing the resin takes some care; the instructions say to mix a 4" ribbon of cream hardener with each 1.5 ounces of resin. My judgement said that about 5 ounces of resin would do the job, and because it was 90 degrees in the garage and resins catalyzed with cream hardener cure very fast, I halved the amount of cream hardener - I used 2 3" lengths of hardener with the 5 ounces, where the instructions would have called for a little over 12". In the photo below I've got 3" marked on a piece of cardboard and I've squeezed out two lengths of cream hardener. The McDonald's medium cup has two marks on the seam, the bottom mark is 5 ounces, so I poured resin to that line and scraped the cream hardener into the resin and mixed it.

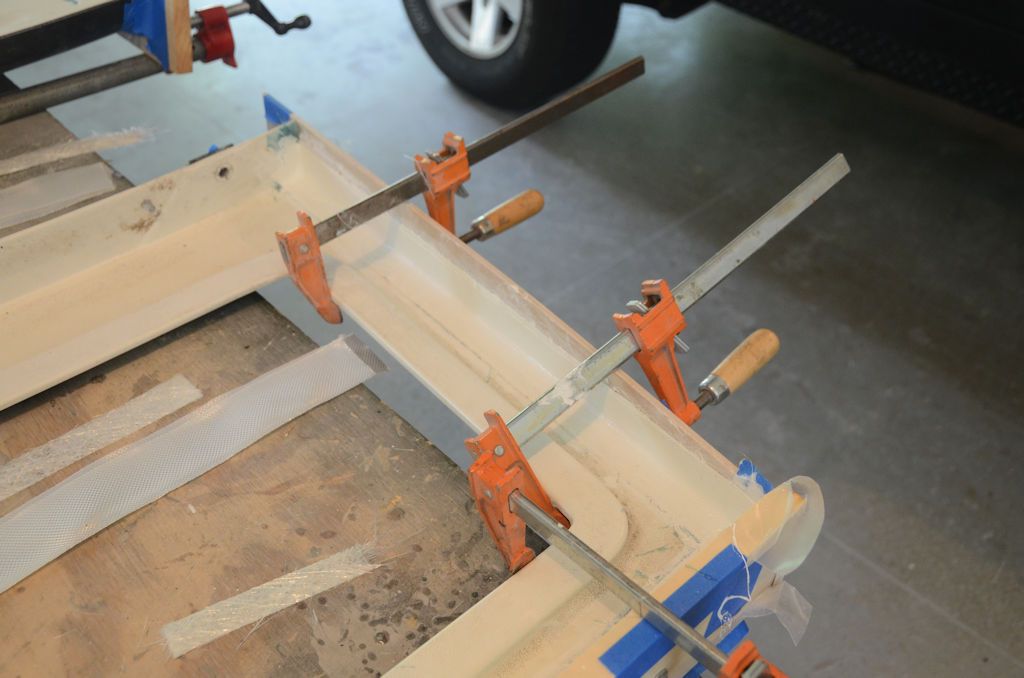

I laid the mat in place, and using a 1" disposable paint brush (a box of them is very inexpensive a Harbor Freight), applied the resin to the mat, being careful to soak the mat completely, and using a stippling action with the brush to push the resin into the mat and make sure the mat is in full contact with the inside of the hardtop and with the form.

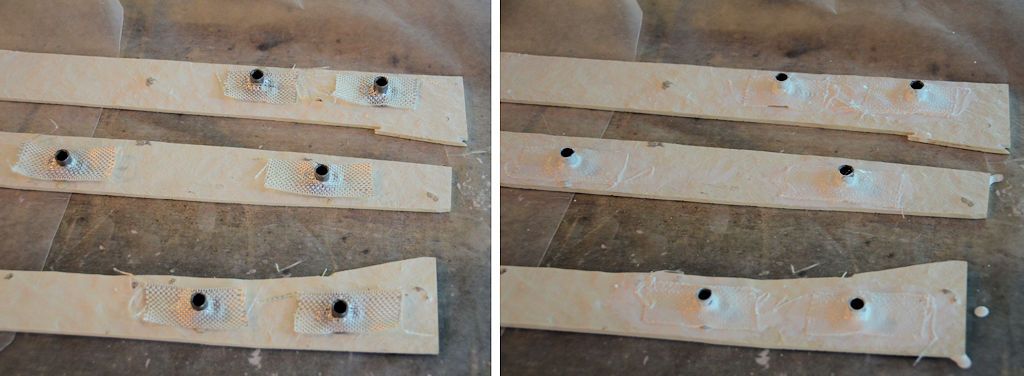

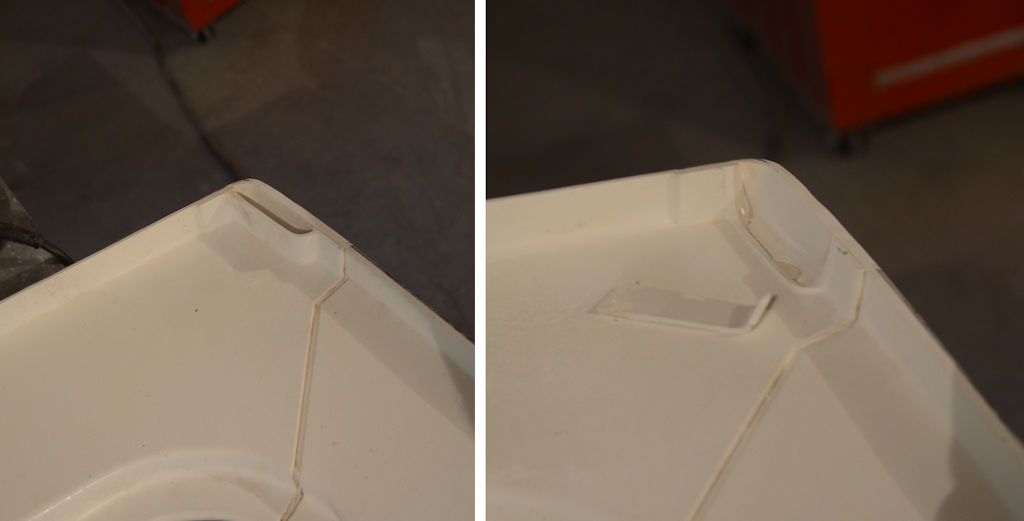

The result looks like this:

I then removed the tape so the curing resin didn't bond it in place.

It turned out that 5 ounces was exactly enough to fully saturate the mat on both side panels and the roof panel.

And even though I halved the amount of hardener, the resin was starting to gel in about 15 minutes, so there wasn't much working time.

Applying the fiberglass cloth tape layers is covered in the next post.

Catalyzing the resin takes some care; the instructions say to mix a 4" ribbon of cream hardener with each 1.5 ounces of resin. My judgement said that about 5 ounces of resin would do the job, and because it was 90 degrees in the garage and resins catalyzed with cream hardener cure very fast, I halved the amount of cream hardener - I used 2 3" lengths of hardener with the 5 ounces, where the instructions would have called for a little over 12". In the photo below I've got 3" marked on a piece of cardboard and I've squeezed out two lengths of cream hardener. The McDonald's medium cup has two marks on the seam, the bottom mark is 5 ounces, so I poured resin to that line and scraped the cream hardener into the resin and mixed it.

I laid the mat in place, and using a 1" disposable paint brush (a box of them is very inexpensive a Harbor Freight), applied the resin to the mat, being careful to soak the mat completely, and using a stippling action with the brush to push the resin into the mat and make sure the mat is in full contact with the inside of the hardtop and with the form.

The result looks like this:

I then removed the tape so the curing resin didn't bond it in place.

It turned out that 5 ounces was exactly enough to fully saturate the mat on both side panels and the roof panel.

And even though I halved the amount of hardener, the resin was starting to gel in about 15 minutes, so there wasn't much working time.

Applying the fiberglass cloth tape layers is covered in the next post.