PlethoraOfGuns

Adventurer

I gotta give a shout out to nutserts. If you don't own a nutsert tool, you're missing out. These things are great and we're going to be using them everywhere in this build!

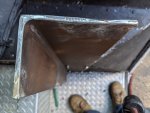

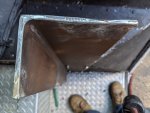

Used to be all these giant "screws" holding everything around the doghouse together.

Installed some nutserts to hold it all together.

All the cross bracing is very thick, structural aluminum. Feel much better with all bolted hardware.

After getting the doghouse back on, got bored and been looking over at the empty passenger seat area. The original stock jumpseat was terrible. I had some spare Jeep seats laying around so this kinda happened.

Had some leftover scrap steel from Belgium laying around. Bolted it through the interior metal into some structural aluminum c-channel.

The old brackets had to go.

Without brackets, things were very flimsy so some other support was welded in.

Bam! Passenger seat!

Mama didn't raise no dummy. The seat we used came out of a 2 door Jeep XJ, so the back folds forward and the whole seat slides forward with a lever and some springs. Now we still have great access to the back through the front! Need to find some plate steel to triangulate the passenger side of the seat bracket. Going to weld a whole piece of that in place and make it very strong and then paint it all. Right now, some flat iron will work as a template while we work on the rest of the buildout.

Used to be all these giant "screws" holding everything around the doghouse together.

Installed some nutserts to hold it all together.

All the cross bracing is very thick, structural aluminum. Feel much better with all bolted hardware.

After getting the doghouse back on, got bored and been looking over at the empty passenger seat area. The original stock jumpseat was terrible. I had some spare Jeep seats laying around so this kinda happened.

Had some leftover scrap steel from Belgium laying around. Bolted it through the interior metal into some structural aluminum c-channel.

The old brackets had to go.

Without brackets, things were very flimsy so some other support was welded in.

Bam! Passenger seat!

Mama didn't raise no dummy. The seat we used came out of a 2 door Jeep XJ, so the back folds forward and the whole seat slides forward with a lever and some springs. Now we still have great access to the back through the front! Need to find some plate steel to triangulate the passenger side of the seat bracket. Going to weld a whole piece of that in place and make it very strong and then paint it all. Right now, some flat iron will work as a template while we work on the rest of the buildout.