Alphamacaroon

Member

I've been experimenting with more economical and locally available alternatives to FRP composite panels. One of the materials that has interested me is corrugated plastic panel (the same stuff they make yard signs). I ran an experiment by creating various composite structures, and vacuum bagging them for maximum adhesion. I figured I would share some of the results here in case anyone was interested.

To start, I went to home depot and purchased some run-of-the-mill 3/16" corrugated plastic sheet made of UV stabilized polypropylene. I also purchased some 1" standard pink XPS insulation foam board and some 3M 90 contact adhesive.

Structure 1

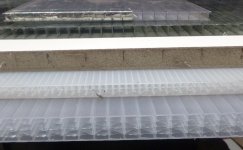

For the first structure, I wanted to make a 1" wall entirely out of cross laminated CPP. I cut 6 pieces of CPP into 2"x6" rectangles and alternated the "grain" for each piece. I sprayed both sides with 3M 90 contact adhesive, waited a few minutes for them to tack up, then assembled all 6 layers in an alternating grain pattern. I put them into a small kitchen vacuum sealer and sealed them into a bag to ensure maximum adhesion contact. I waited 12 hours, then opened it up.

I had a couple of concerns— 1) I thought that the contact adhesive (being solvent based) would not properly cure in vacuum conditions, and 2) I thought that the pressure of vacuum would crush or deform the corrugated channels.

Results:

Structure 2

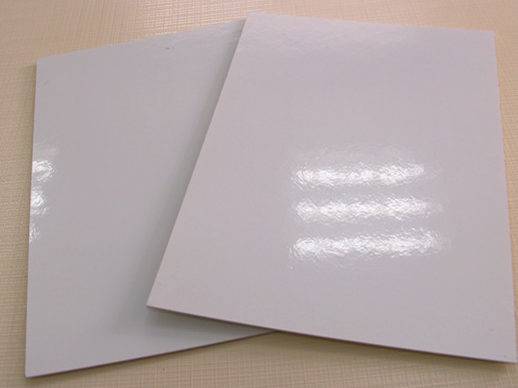

For the next structure I wanted to try something that was closer to FRP composite panels, but using the CPP as the outer layer/skin instead of FRP. I followed the same process as the previous structure, but instead of six layers of CPP, I sandwiched the XPS foam between two layers of CPP.

Results:

Conclusions

Very interested in hearing from other builders about their experience with this or similar materials and or pointers to existing threads on the topic.

To start, I went to home depot and purchased some run-of-the-mill 3/16" corrugated plastic sheet made of UV stabilized polypropylene. I also purchased some 1" standard pink XPS insulation foam board and some 3M 90 contact adhesive.

Structure 1

For the first structure, I wanted to make a 1" wall entirely out of cross laminated CPP. I cut 6 pieces of CPP into 2"x6" rectangles and alternated the "grain" for each piece. I sprayed both sides with 3M 90 contact adhesive, waited a few minutes for them to tack up, then assembled all 6 layers in an alternating grain pattern. I put them into a small kitchen vacuum sealer and sealed them into a bag to ensure maximum adhesion contact. I waited 12 hours, then opened it up.

I had a couple of concerns— 1) I thought that the contact adhesive (being solvent based) would not properly cure in vacuum conditions, and 2) I thought that the pressure of vacuum would crush or deform the corrugated channels.

Results:

- The glue appears to have cured just fine. I've tried with all my might to delaminate the layers and can't. I've heard that contact adhesive can degrade over time and with heat so maybe it's not a perfect long-term solution, but during the experimentation phase it is seems more than sufficient.

- There does appear to be a small amount of deformation of the corrugated channels, but it's extremely hard to tell. I put all 275lbs of my weight on to the test panel and did not notice any deformation or buckling in the compression axis.

- I plan to do more thorough deflection testing on larger samples, but I can barely deflect the wall by trying to break it in half with my fingers and thumbs. Any deflection instantly springs back to true the moment pressure is released.

- The sample is completely flat and does not show any signs of warping or deformation.

- The 2"x6" sample weighs 45 grams on my kitchen scale, which works out to roughly 1.191 lbs per square foot.

- At a cost of about $0.50 per square foot for one sheet of CPP, I can create a roughly 1" thick wall (5 layers) for $2.50 per square foot.

Structure 2

For the next structure I wanted to try something that was closer to FRP composite panels, but using the CPP as the outer layer/skin instead of FRP. I followed the same process as the previous structure, but instead of six layers of CPP, I sandwiched the XPS foam between two layers of CPP.

Results:

- I had some concerns that the 3M 90 would melt the XPS, but a few searches online seemed to indicate it would be compatible. It was not. The foam did start to melt, but since contact adhesive doesn't require a large amount to begin with, the melting seemed to be limited to a small amount at the surface. Who knows, it may have even aided in adhesion because I cannot separate the layers even if I try.

- The sample is not perfectly flat and there does seem to be some deformation in areas. This is almost certainly caused by the incompatible glue melting the underlying XPS, and I'm sure will be eliminated when a better glue is used.

- The sample appears to be as strong or stronger in the deflection axis.

- The compression axis is a different story. When squeezed tightly or weight is put on top of it, the foam layer appears to compress. This may be eliminated by experimenting with other types of foam that can be obtained from local sources.

- The weight for this sample was 21 grams which works out to roughly 0.55 lbs per square foot.

- With an average cost of XPS foam of $1.50 per square foot, plus 2 layers of CPP at $0.50 per square foot, it should work out to roughly the same cost of $2.50 per square foot.

Conclusions

- The cross-layer CPP composite, while heavier, seems like it could be more suited for flooring structures, while the XPS foam core composite seems more suitable for wall structures.

- Strength tests will need to be performed with larger samples, but it's clear to me that these composites will be more than suitable for many applications where a waterproof, lightweight, durable wall or floor material is needed.

- While the panels appear to be sufficient from a strength perspective, the durability may not be quite on par with FRP. I suspect that gouges and sharp edges will more easily damage the surface layers, but because it's multi-layered this type of damage would be mostly superficial. It should also be possible to repair cuts and gouges with melted plastic similar to how plastic kayaks are repaired. Finally, because the cost is orders of magnitude cheaper than FRP composites, entire panels could be replaced multiple times over and still be cheaper in the long run.

- The plastic is supposed to be UV stabilized, but it will be interesting to see how it performs over time.

- Insulation testing should be performed. My assumption is that the XPS core composite should be nearly as good as FRP composites (maybe even better), but the cross-layer composite may be slightly worse.

- Because CPP is mostly used for advertising, it is very easy to obtain it in different colors and finishes as well as the ability to be printed on.

- While it's relatively easy to build a vacuum bagging system in your garage, there is no reason this approach would not also work with a simple flat board and weights.

- I've seen figures of 1.75 lbs to 2.25 lbs per square foot for FRP composite panels, so if that figure is right, these panels are 50-75% lighter.

- If we figure FRP composite panels cost anywhere from $10-$20 per square foot, these panels can be made for 4-8X cheaper with materials you can find at your local hardware store or sign shop.

Very interested in hearing from other builders about their experience with this or similar materials and or pointers to existing threads on the topic.

Last edited: