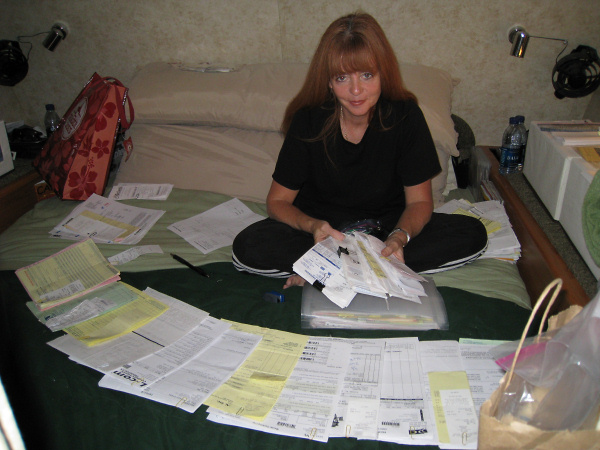

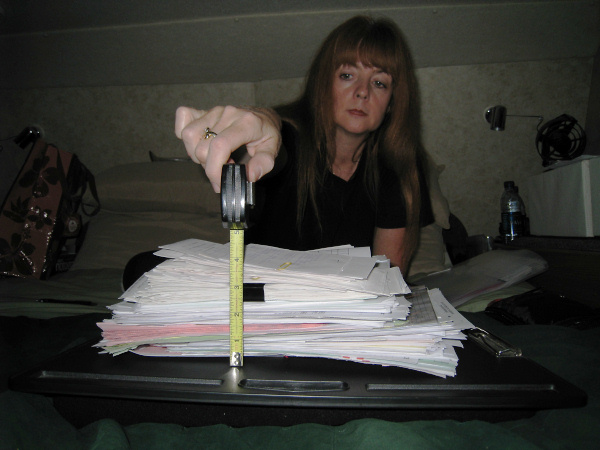

After a huge project by Steph collating and organizing all of the project receipts and hours on the laptop by me updating the cost spreadsheets I abandoned last December, we finally have a definative answer to the question,

"What did it cost?"

We now know, without any doubt, that the project cost us exactly four inches.

For those interested in a different means of measuring cost, here are some specifics on the basic elements of the project:

2007 Mitsubishi Fuso FG 140 $36,187.50

Includes all fees, etc. - total out the door price. Kearny Mesa Truck Center, San Diego.

2006 Bigfoot 30C10.11FR $31,920.00

Includes all dealer fees, options, etc. You can do a lot better than this price. There were only two left in the country at the time, so we didn't have much leverage.

External storage boxes, garage, etc. $5,711.00

This includes all external locking storage boxes, spare tire boxes, etc. Fleet Metal Box (FMB), Colton, CA

Aluminum custom fuel tanks $1,682.00

Stainless steel raw water tank $1,265.00

Three point pivot frame: $ will depend on your fabrication costs. For design ideas, etc. click here:

http://www.hackneys.com/mitsu/index-pivot-frame.htm

If you know someone who can fabricate, you can create the basic concept for about $100,000. Obviously, if you can fabricate yourself, you can do it for these costs and the raw material costs, which will be significantly less.

The rest of our total cost is in all those receipts: all the marine grade materials, marine systems, equipment and capabilities that we added to the rig.

Tonight was the first time we've had a cost total that we felt was complete and detailed enough to be pretty close to what our total investment was. It actually turned out to be less than I thought.